Permanent-magnet synchronous motor, and power generation alternating operation system and adjusting method

A technology of permanent magnet synchronous motor and alternating operation, which is applied in the direction of electromechanical devices, control systems, electric components, etc., and can solve the problems of wasting electric energy, stator winding current pulsation, and large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

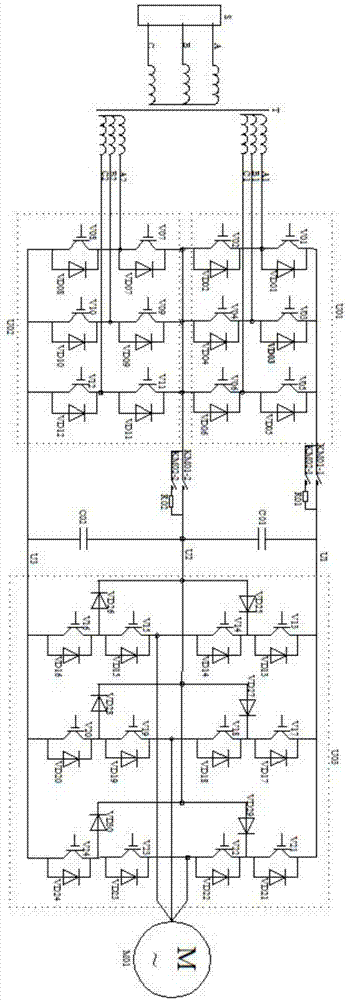

[0087] This embodiment provides a permanent magnet synchronous motor electric and power generation alternate operation system, figure 1 It is a schematic diagram of the circuit structure of the permanent magnet synchronous motor motor-generation alternating operation system according to Embodiment 1 of the present invention, as figure 1 As shown, the permanent magnet synchronous motor electric and power generation alternate operation system includes a transformer T, a three-phase full-bridge four-quadrant rectifier circuit U01, a three-phase full-bridge four-quadrant rectifier circuit U02, a DC voltage variable three-phase inverter circuit U03, Permanent magnet synchronous motor; when the permanent magnet synchronous motor is used as a motor, the energy is transmitted from the grid to the motor, and when the permanent magnet synchronous motor is used as a generator, the energy is input from the permanent magnet synchronous motor to the grid, that is, the system has a bidirectio...

Embodiment 2

[0116]When the permanent magnet synchronous motor operates at a constant speed, since the rotation speed of the rotor and the rotation speed of the equivalent magnetic pole of the stator are equal, the rotation speed of the rotor is determined by the rotation speed of the equivalent magnetic pole of the stator, and the rotation speed of the equivalent magnetic pole of the stator Determined by the frequency of the current in the three-phase windings of the stator. As the load changes, the amplitude of the current in the stator three-phase winding also needs to change accordingly, otherwise, if the amplitude of the stator three-phase winding current is too small, it will cause out of step, and if the amplitude of the stator three-phase winding current is too large, then Excessive excitation current will be caused.

[0117] When the permanent magnet synchronous motor is running as a motor, the rotor rotation angle is measured through the encoder, and the rotation angle of the sta...

Embodiment 3

[0137] When the permanent magnet synchronous motor operates as a generator, the energy needs to be transmitted to the DC link through the DC voltage variable three-phase inverter circuit U03.

[0138] The permanent magnet synchronous motor operates in the generator state, and the phase of the stator winding terminal voltage needs to be ahead of the phase of the stator winding current, and the phase difference is greater than 90°.

[0139] This embodiment is the constant speed control method of the permanent magnet synchronous motor of embodiment 1, which operates alternately as electric motor and generator:

[0140] Step 1: Install an encoder detector in the permanent magnet synchronous motor to detect the position of the encoder in real time, that is, the angle of rotation of the rotor.

[0141] Step 2. Before the permanent magnet synchronous motor is put into operation, the phase relationship between the encoder and the three-phase stator current is calibrated mappingly. At ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com