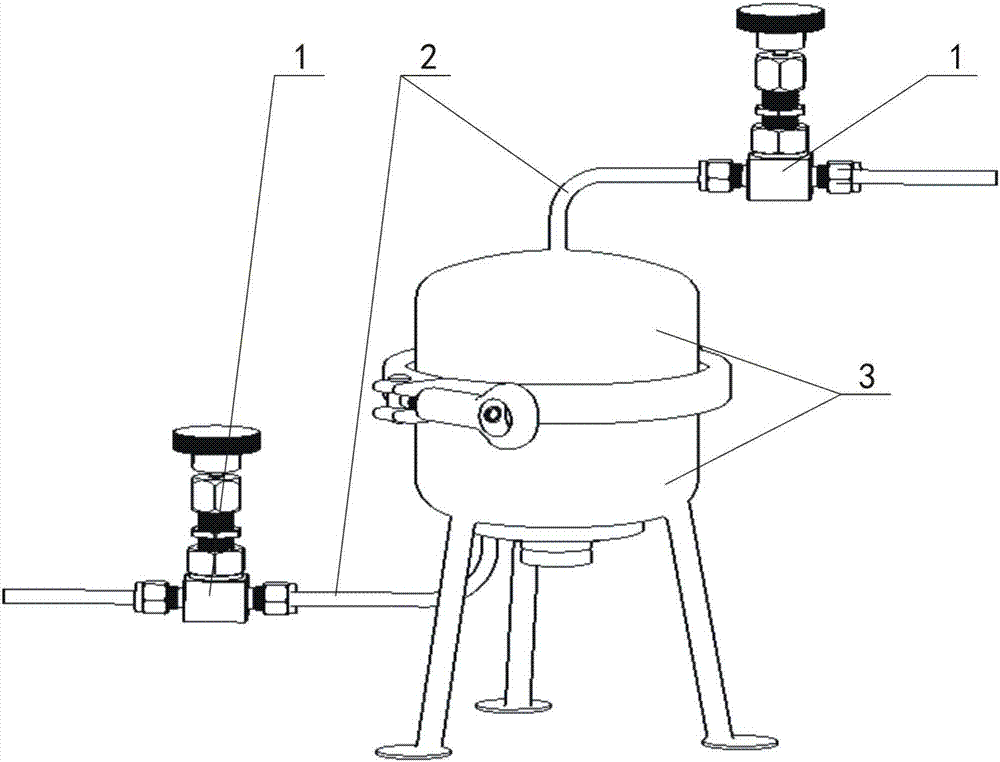

Assembled gas sensor calibration apparatus

A sensing standard and component-based technology, applied in measuring devices, analyzing gas mixtures, standard gas analyzers, etc., can solve problems such as low installation and use efficiency, inconvenient operation and carrying, and influence on atmosphere monitoring, and achieve easy operation, Easy loading and unloading, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

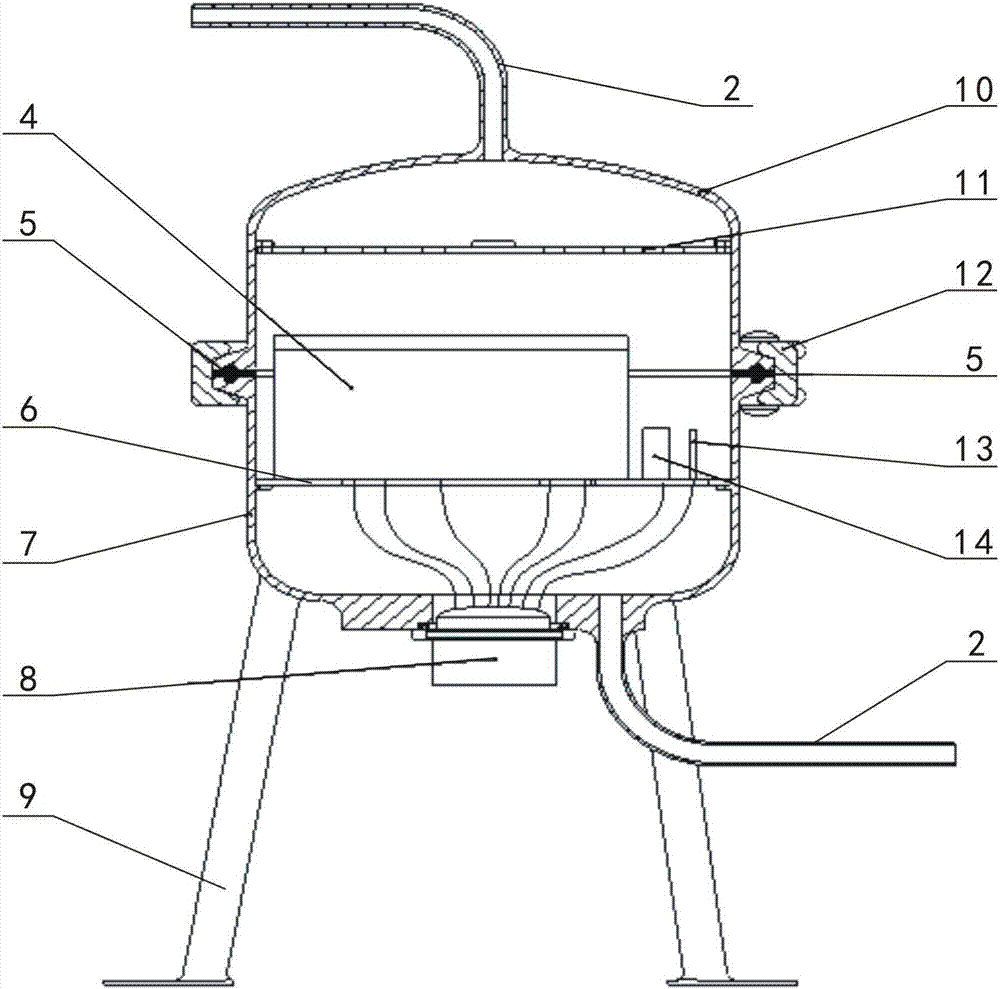

[0019] The present invention will be further described below in conjunction with accompanying drawing:

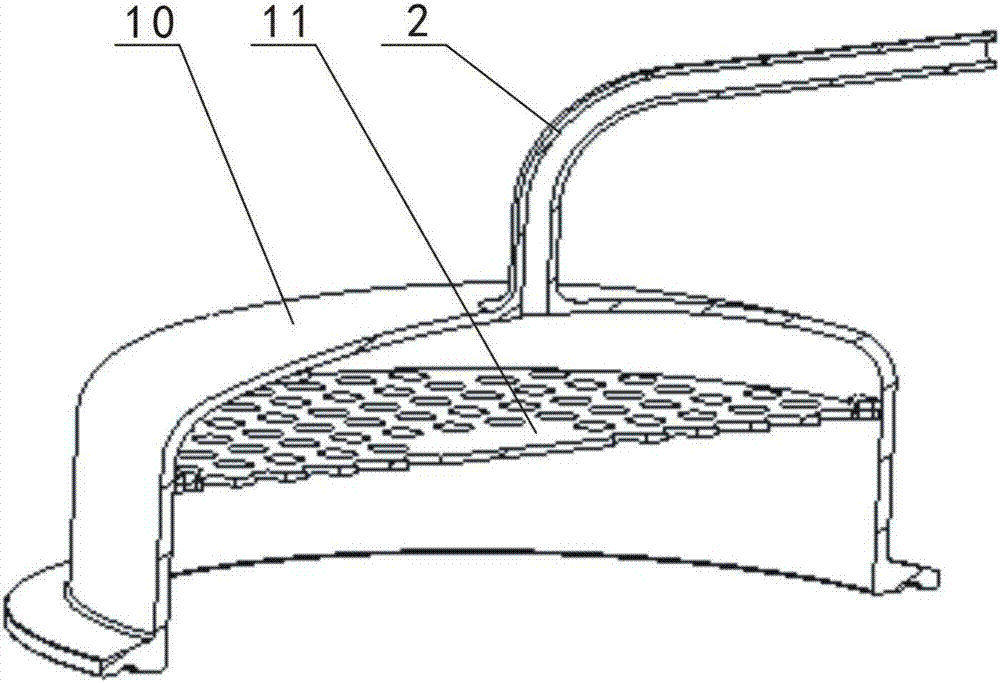

[0020] Such as Figure 1-Figure 6 As shown, the component type gas sensing calibration device 3 of the present invention includes an upper sealed tank 10, a lower sealed tank 7, an air distribution plate 11, a clamp 12, a sealing ring 5, a device mounting plate 6, a gas test component 4, a temperature The sensor 13, the pressure sensor 14 and the wire connector 8, the gas test assembly 4 is an assembly formed by installing the signal conditioning circuit and the gas sensitive element in a metal box and encapsulating the signal conditioning circuit with silicone gel. The upper part of the airtight tank 10 is provided with an air pipe 2 for air intake and a valve 1 is installed on the air pipe 2, and a plurality of vertical air holes 111 with a diameter of 1.5 to 3 mm are provided on the horizontal air distribution plate 11. The air flow distribution plate The central positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com