Cathode active material of lithium ion secondary battery, preparation method of cathode active material, cathode pole piece of lithium ion secondary battery and lithium ion secondary battery

A negative electrode active material, secondary battery technology, applied in secondary batteries, active material electrodes, battery electrodes, etc., can solve the problems of low charge and discharge performance, poor fast charging performance, poor fast charging ability, etc. The effect of high, lowering the reverse lithium storage stress barrier, and increasing the binding site of lithium storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] Correspondingly, the embodiment of the present invention also provides a preparation method of the negative electrode active material of the lithium ion secondary battery, comprising the following steps:

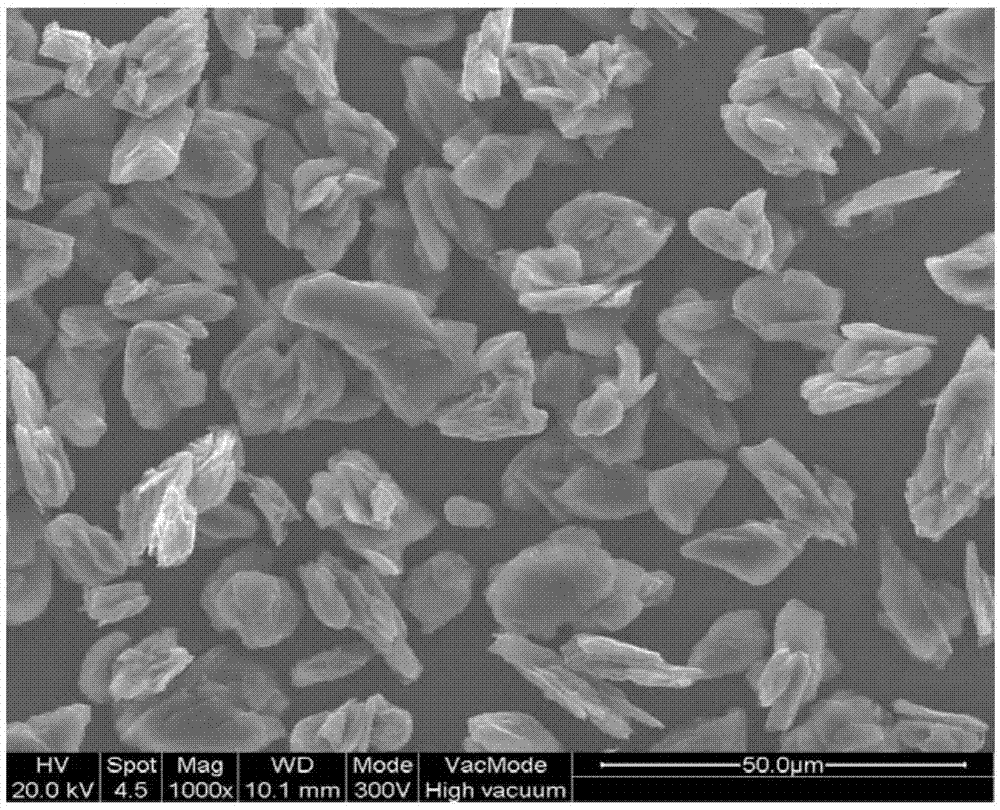

[0052] Mix carbon materials, amorphous carbon raw materials and ionic liquids to obtain a mixture; put the mixture into a reaction kettle, and pass a mixed gas of small organic molecules containing doping elements and an inert carrier gas, at 500-1200 The negative electrode active material of the lithium ion secondary battery is obtained by keeping the temperature for 1-12 hours at a temperature of ℃, and the negative electrode active material of the lithium ion secondary battery includes a carbon material inner core and a coating formed on the surface of the carbon material inner core layer, the material of the cladding layer includes amorphous carbon and a doping element, the doping element includes nitrogen, the cladding layer has a single-layer structure, and the d...

Embodiment 1

[0077] A preparation method for a negative electrode active material of a lithium ion secondary battery, comprising the following steps:

[0078] (1) Weigh 3.0kg of artificial graphite, 0.3kg of petroleum pitch crushed to less than 0.1mm, and 0.02kg of phenolic resin, stir evenly and put them into the reaction kettle, heat and coat at 500°C for 2 hours, and then pass nitrogen gas Protection, carbonization treatment at 1000°C for 4 hours, and then cooling the reaction product to room temperature to obtain artificial graphite coated with amorphous carbon;

[0079] (2) cetyltrimethylammonium bromide (CTAB, 0.5kg) is dissolved in the HCl (8L, 1mol / L) solution of ice-water bath to obtain the first mixed solution, and the above-mentioned gained amorphous carbon-coated Add 2.0kg of artificial graphite to the above first mixed solution, ultrasonically disperse for 30 minutes, then add ammonium persulfate (APS, 0.8kg) into it, immediately form a white suspension, stir for 0.5 hours, th...

Embodiment 2

[0083] A preparation method for a negative electrode active material of a lithium ion secondary battery, comprising the following steps:

[0084] (1) Dissolve cetyltrimethylammonium bromide (CTAB, 0.5kg) in the HCl (8L, 1mol / L) solution in ice-water bath to obtain the first mixed solution, take 2.0kg of artificial graphite and add it to the above-mentioned first In a mixed solution, ultrasonically disperse for 30 minutes, then add ammonium persulfate (APS, 0.8kg) therein, immediately form a white suspension, after stirring for 0.5 hours, add 0.5L pyrrole monomer to obtain the second mixed solution, The second mixed solution was incubated and reacted at 4° C. for 24 hours and then filtered to obtain a black precipitate. The black precipitate was washed three times with 1 mol / L HCl solution, and then washed with pure water until the solution was colorless and neutral. Then the precipitate was dried at 80° C. for 12 hours to obtain the dried precipitate; then the dried precipitat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com