Novel resene-based nanocomposite and preparation method, regeneration method and application thereof

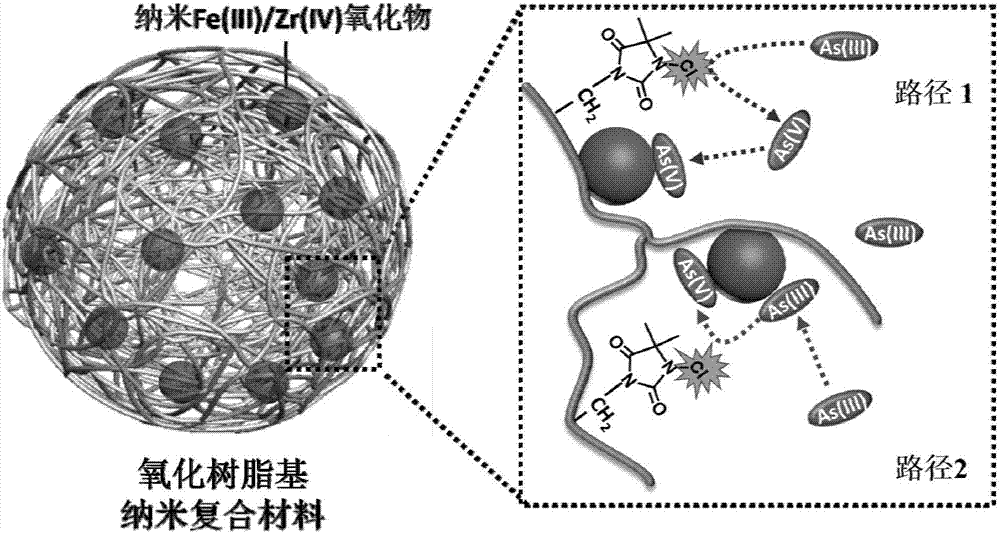

A nano-composite material and resin oxidation technology, applied in chemical instruments and methods, separation methods, filter regeneration, etc., can solve problems such as difficulty in regeneration, poor removal of trivalent arsenic, etc., and achieve the effect of avoiding covering and adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

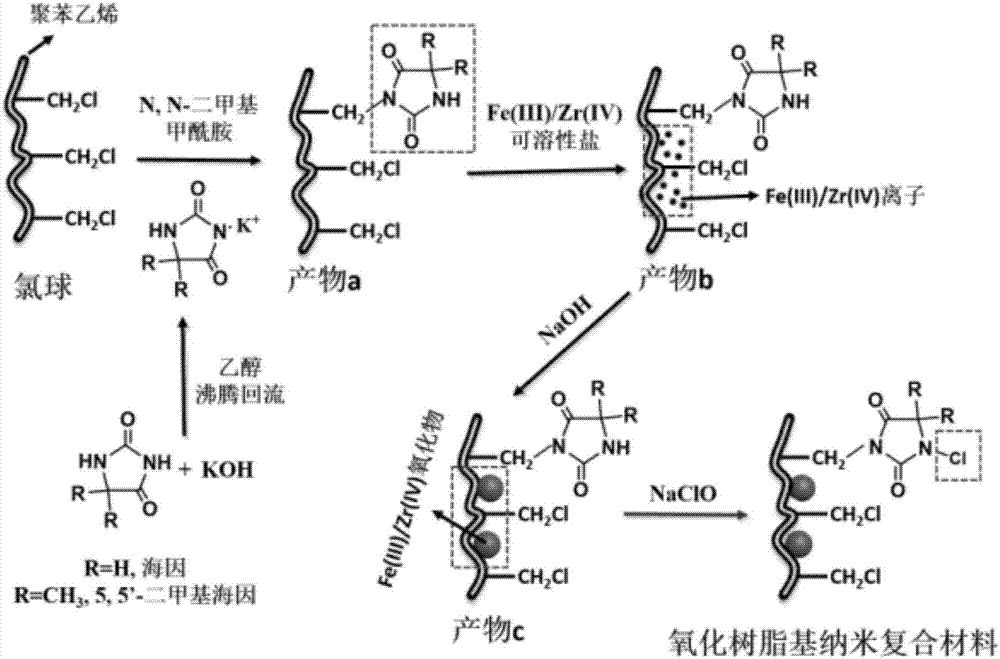

[0041] A kind of preparation method of novel oxidized resin-based nanocomposite material, its implementation steps are as follows (preparation process is as follows: figure 2 shown):

[0042] (1) Add 1.02g of 5,5'-dimethylhydantoin and 0.45g of KOH to 20mL of absolute ethanol, boil and reflux for 6h, and dry the obtained white potassium salt;

[0043] (2) Weigh 1.0 g of the white potassium salt obtained in step (1), add it to 20 mL of N, N'-dimethylformamide (DMF) to dissolve it, add 2.0 g of chloromethylated styrene-di Vinylbenzene copolymerized spheres, heated at 60°C for 12h;

[0044] (3) Add the product obtained in step (2) to 20mL containing 0.9M FeCl 3 In the solution, take out after stirring reaction at room temperature for 24h;

[0045] (4) Slowly add the product obtained in step (3) into 20 mL of 10% NaOH solution, stir and react at room temperature for 6 hours, then remove and wash until neutral;

[0046] (5) Add the product obtained in step (4) to 20mL of 8% Na...

Embodiment 2

[0049] A preparation method of an oxidized resin-based nanocomposite material, its implementation steps are similar to those in Example 1, only the boiling reflux time in step (1) is changed to 3h, the heating temperature in step (2) is changed to 50°C, and the reaction time is changed to For 26h, FeCl in step (3) 3 Change the concentration of 1.5M into 1.5M, change the reaction time into 6h, change the reaction time into 3h in the step (4), adjust the pH of the solution to 4 by 0.1mmol / LHCl in the step (5), change the reaction temperature into 50°C, and change the reaction time into for 12h.

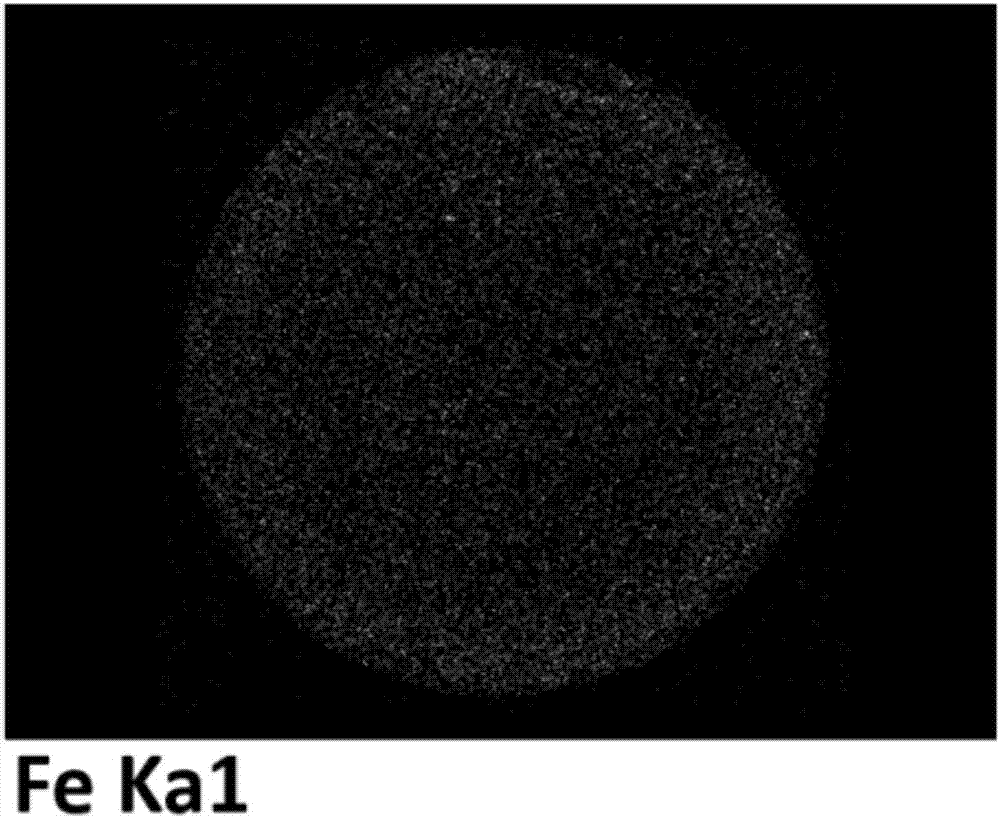

[0050] The active chlorine content of the composite material obtained in this embodiment is 1.3mmol / g, the iron loading is 12%, and the Fe element is evenly distributed; the specific surface area of the composite material is 60m 2 / g, the distribution of nanometer hydrated iron (III) oxide particles is 5-100nm.

Embodiment 3

[0052] A preparation method of an oxidized resin-based nano-composite material, the implementation steps of which are similar to those in Example 1, only changing the boiling reflux time to 12 hours in step (1), changing the heating temperature to 90°C and changing the reaction time to For 20h, FeCl in step (3) 3 The concentration of the solution is changed to 0.1M, the reaction time is changed to 12h, the reaction time is changed to 12h in the step (4), the solution pH is adjusted to 6 by 0.1mmol / LHCl in the step (5), the reaction temperature is changed to 90°C, and the reaction time is changed for 36h.

[0053] The composite material obtained in this example is a spherical particle with a diameter of 0.8 mm. According to "2.1 Iodine Method" in "Standard Test Method for Drinking Water: Disinfectant Index" (GB / T 5750.11-2006), the active chlorine content of the composite material is measured to be 1.5mmol / g; The amount of iron loading measured by flame atomic absorption meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com