Step-by-step desiliconizing and upgrading method for high-aluminum and high-silicon bauxite

A technology for desiliconization of bauxite, which is applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of high chemical consumption in flotation, high separation cost, and high energy consumption in grinding, so as to avoid desiliconization. Poor silicon effect, reduced amount of beneficiation, simple and flexible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

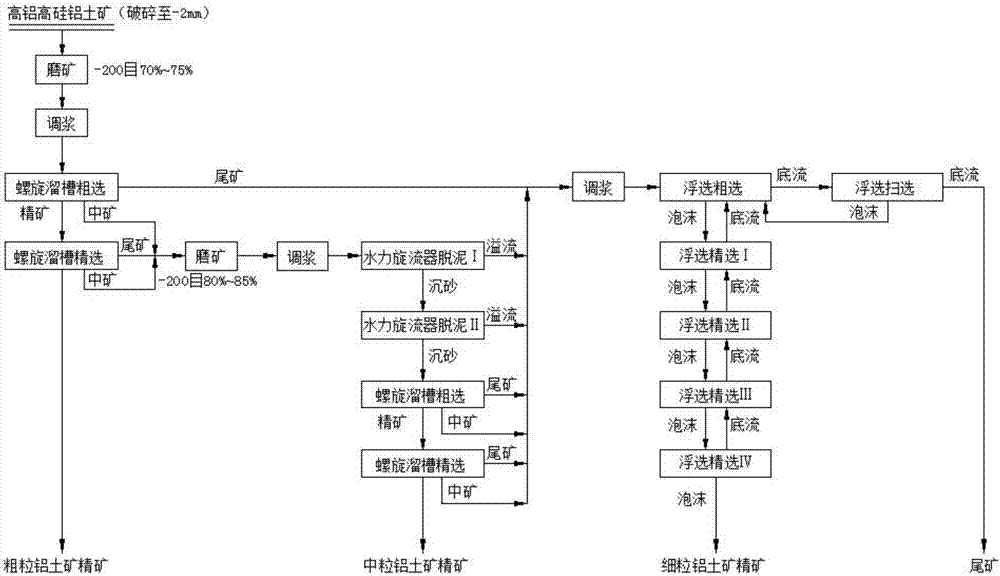

[0026] Such as figure 1 As shown, the step-by-step desiliconization and upgrading method of this high-alumina and high-silicon type bauxite, its specific steps are as follows:

[0027] (1) The first step of gravity desiliconization in the spiral chute: the high-aluminum high-silicon bauxite (mine sample I), which contains Al 2 o 3 65.41wt%, SiO 2 13.15wt%, the aluminum-silicon ratio (A / S) is 4.97, the main aluminum minerals are diaspore (48.21wt%) and boehmite (17.20wt%), and the remaining gangue minerals are kaolinite, Mainly illite and quartz. The ore sample was crushed, screened and ground to -200 mesh to account for 70%, water was added to adjust the slurry concentration to 15% (m / v), and a spiral chute was used to carry out a roughing and a beneficiation respectively, and the concentrate of the spiral chute was Coarse-grained bauxite concentrate.

[0028] (2) The second step of hydrocyclone combined with spiral chute gravity desiliconization: the rough ore selection ...

Embodiment 2

[0032] Such as figure 1 As shown, the step-by-step desiliconization and upgrading method of this high-alumina and high-silicon type bauxite, its specific steps are as follows:

[0033] (1) The first step of gravity desiliconization in the spiral chute: the high-aluminum high-silicon bauxite (mine sample II), which contains Al 2 o 3 66.57wt%, SiO 2 12.42wt%, the aluminum-silicon ratio (A / S) is 5.36, the main aluminum minerals are diaspore (52.03wt%) and boehmite (14.54wt%), and the remaining gangue minerals are kaolinite, Mainly muscovite and quartz. The ore sample was crushed, screened and ground to -200 mesh to account for 70%, water was added to adjust the slurry concentration to 15% (m / v), and a spiral chute was used to carry out a roughing and a beneficiation respectively, and the concentrate of the spiral chute was Coarse-grained bauxite concentrate.

[0034] (2) The second step of hydrocyclone combined with spiral chute gravity desiliconization: the rough ore selectio...

Embodiment 3

[0038] Such as figure 1 As shown, the step-by-step desiliconization and upgrading method of this high-alumina and high-silicon type bauxite, its specific steps are as follows:

[0039] (1) The first step of gravity desiliconization in the spiral chute: the high-aluminum high-silicon bauxite ore (mine sample III), which contains Al 2 o 3 64.78wt%, SiO 2 12.82wt%, the aluminum-silicon ratio (A / S) is 5.05, the main aluminum minerals are diaspore (49.53wt%) and boehmite (15.25wt%), and the rest of the gangue minerals are quartz, leaf wax Stone, kaolinite and so on. The ore sample was crushed, screened and ground to -200 mesh to account for 75%, water was added to adjust the pulp concentration to 20% (m / v), and a spiral chute was used to carry out a roughing and a beneficiation respectively, and the concentrate of the spiral chute was Coarse-grained bauxite concentrate.

[0040] (2) The second step of hydrocyclone combined with spiral chute gravity desiliconization: the rough ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com