Barrier film for solar back sheet and preparation method thereof

A technology for solar backplanes and solar panels, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve problems such as poor water vapor barrier properties, achieve high water vapor barrier properties and hydrolysis resistance, and prepare The method is simple and the process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the barrier film for solar back panel provided by the invention comprises the following steps:

[0022] (1) Granulation: Mix polyester resin, nano-inorganic particles, chain extender, nucleating agent and dispersant evenly and carry out twin-screw mixing and granulation to obtain polyester functional masterbatch;

[0023] (2) Cast sheet: three-layer co-extrusion process is adopted; the material of layer A is PEN, and for layer B, the polyester resin and the polyester functional masterbatch obtained in step (1) are mixed according to the ratio, and then ABA three-layer co-extrusion is carried out Melting plasticization, cast casting;

[0024] (3) Stretching to form a film: longitudinally stretching, transversely stretching, heat-setting, winding and packaging the cast sheet obtained in step (2) to obtain a barrier film for a solar backplane.

[0025] The particle size of the nano inorganic filler is 0.2-0.6 μm. The polyester resin used in Exam...

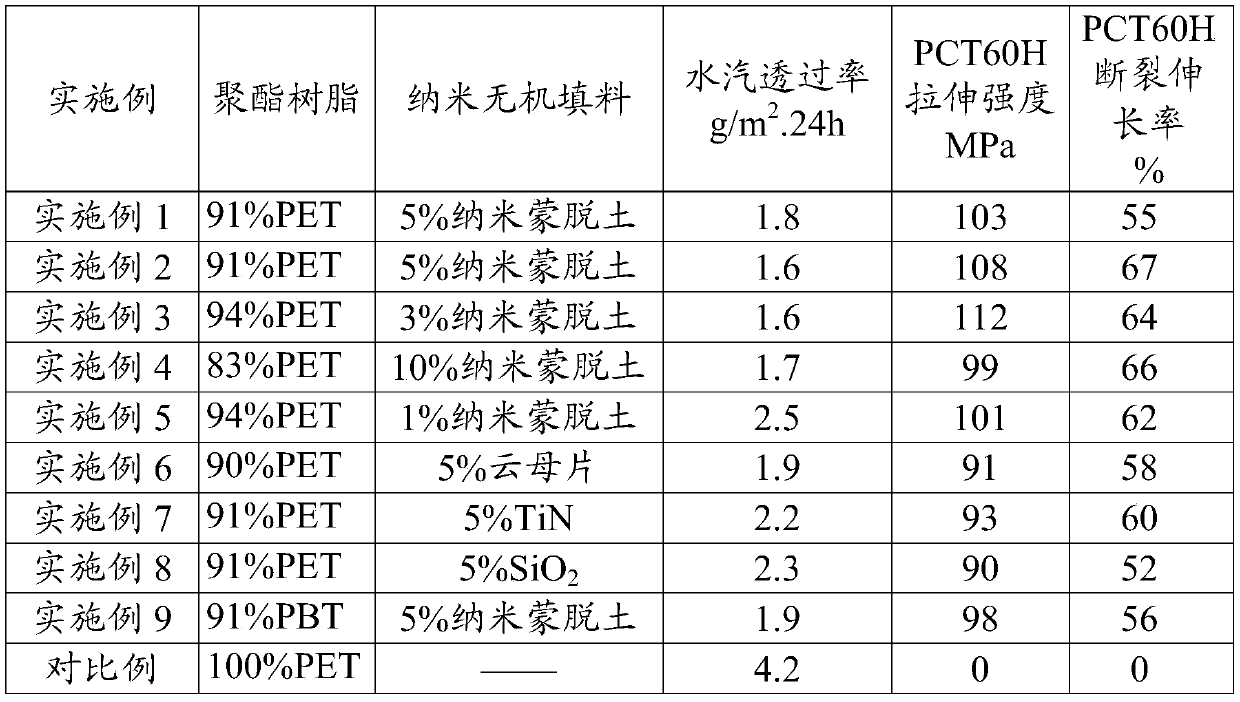

Embodiment 1

[0030] In the barrier film for solar back panels provided by the present invention, the raw materials of the B layer of the barrier film include the following components: 91% of PET resin, 5% of nano-montmorillonite, 0.5% of carbodiimide, and NA-10 nucleating agent 2%, polyethylene wax 1.5%. The barrier film is an ABA three-layer co-extrusion structure, and the thickness of the barrier film is 250 μm, wherein, the thickness of the A layer accounts for 8% of the total thickness, and the thickness of the B layer accounts for 92% of the total thickness. The relevant properties are shown in Table 1.

Embodiment 2

[0032] In the barrier film for solar back panels provided by the present invention, the raw materials of the B layer of the barrier film include the following components: 91% of PET resin, 5% of nano-montmorillonite, 1.5% of carbodiimide, and NA-10 nucleating agent 1.5%, polyethylene wax 1.0%. The barrier film is an ABA three-layer co-extrusion structure, and the thickness of the barrier film is 250 μm, wherein, the thickness of the A layer accounts for 10% of the total thickness, and the thickness of the B layer accounts for 90% of the total thickness. The relevant properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com