A kind of polymerization granulation system and method

A technology of granulation and granulation machine, which is applied in the direction of coating, etc., can solve the problems of the influence of output rate and the decrease of melt flow rate, etc., and achieve the effect of temperature control, fluidity maintenance and increase of output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

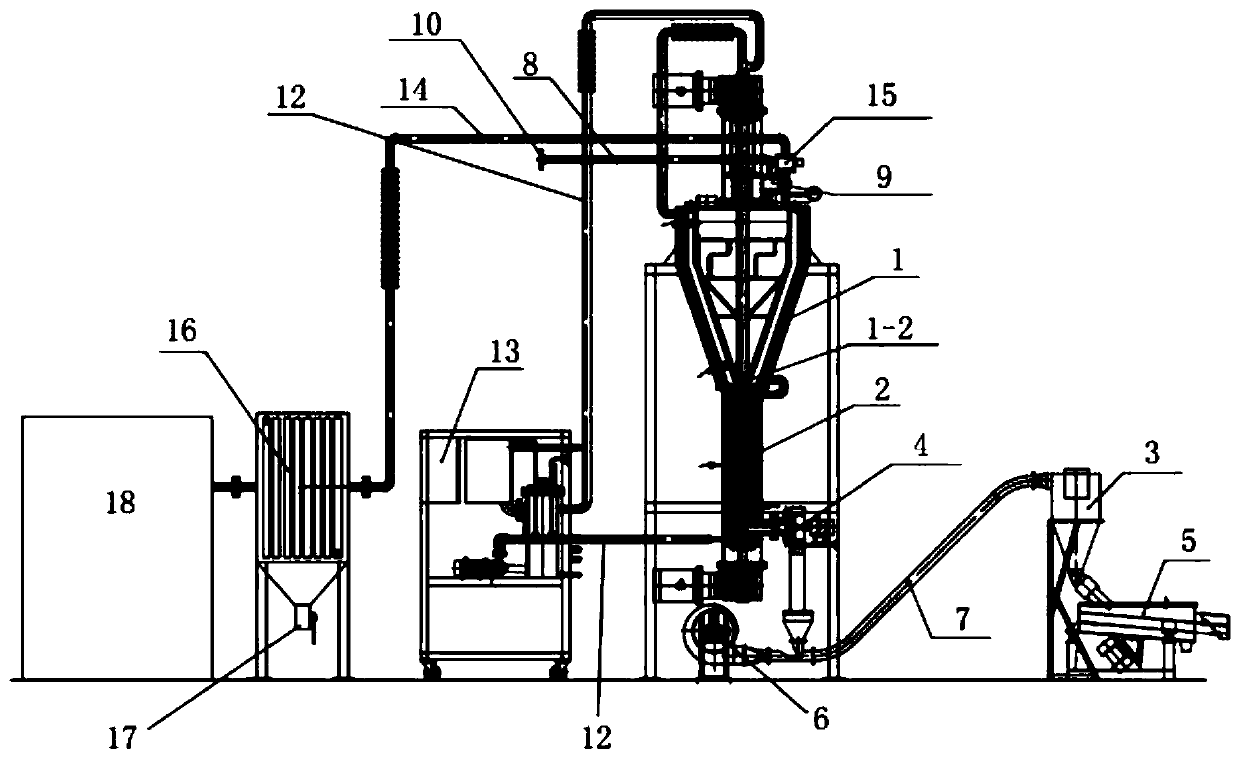

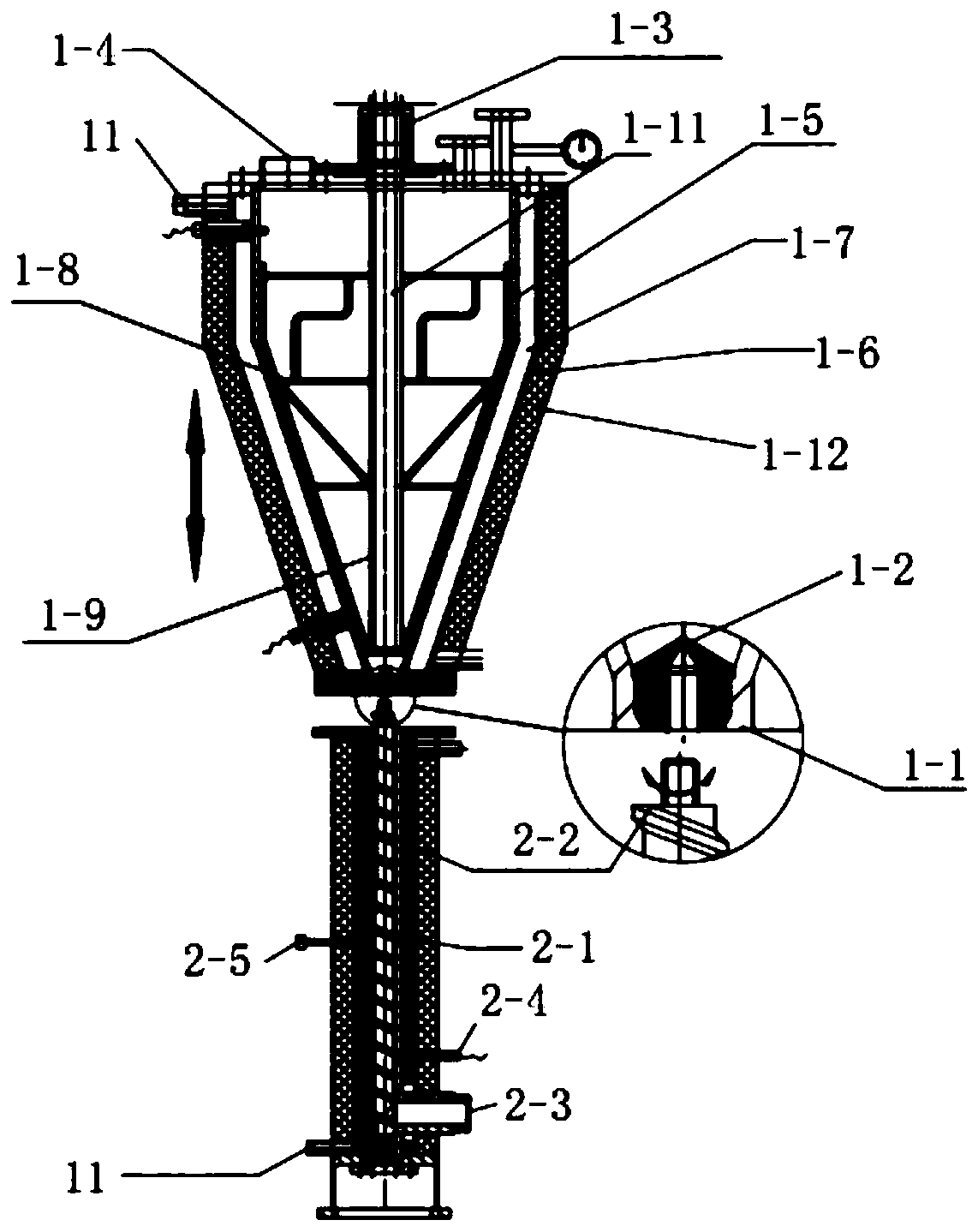

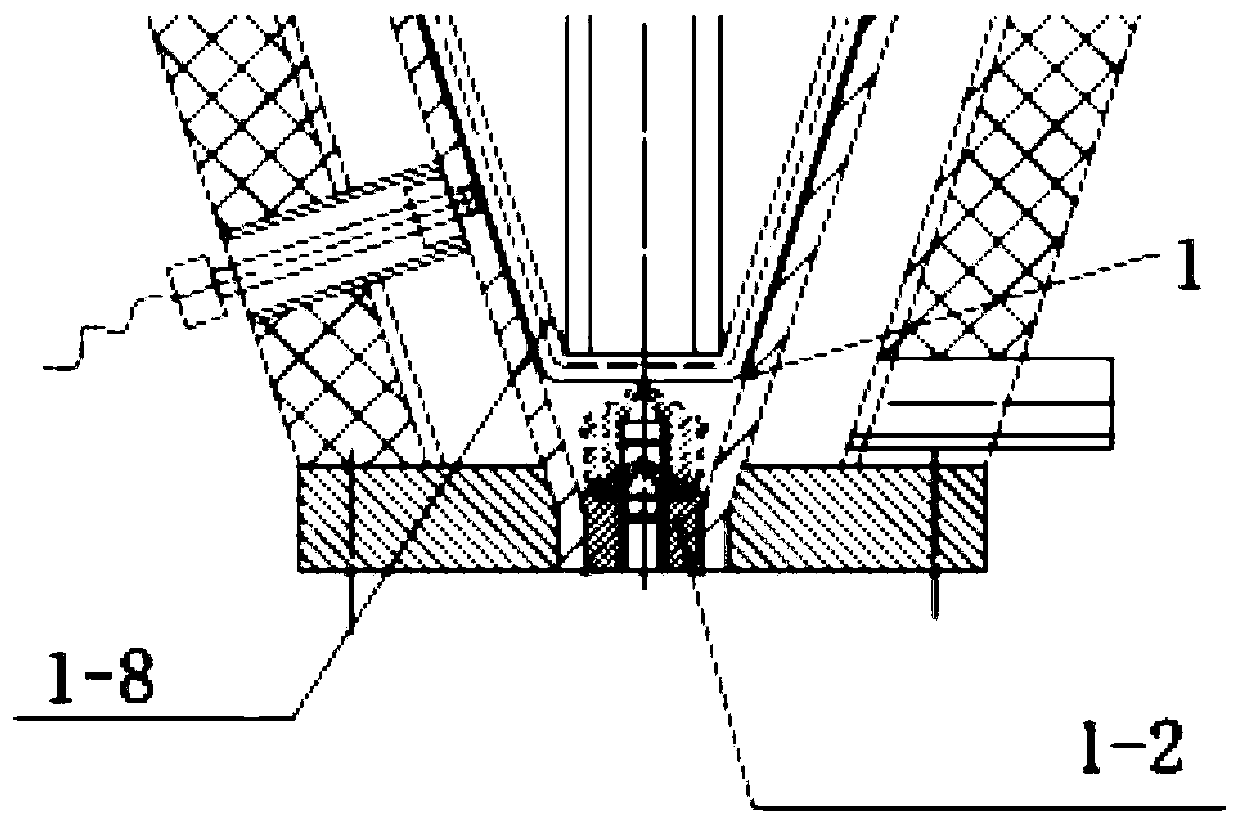

[0048] The present invention is a kind of polymerization granulation system used in the manufacturing process of thermotropic liquid crystal polymer, see figure 1 , the device mainly includes a reaction kettle 1, an extruder 2, a cyclone hopper 3, a granulator 4, a vibrating screen 5, a heating system, and a vacuum system. The reaction kettle 1 is connected with an extruder 2, a granulator 4, The cyclone silo 3 and the vibrating screen 5, the discharge port 1-1 of the reactor is opposite to the extruder 2, so that the melt in the reactor 1 flows out through the screw 2-2 of the extruder 2, and the extruder discharges The port 2-3 is connected to the granulator 4, and the discharge port of the granulator 4 is connected to the feeding pipe 7 to form a material transportation chain. One end of the feeding pipe 7 is connected to a feeding fan 6, and the extruded material passes through the granulator 4. After granulation, it is sent into the cyclone silo 3 through the feeding fan ...

Embodiment 2

[0060] The present invention also provides a kind of polymerization granulation method in addition, and this method comprises the following steps:

[0061] a. Connect reactor 1, extruder 2, granulator 4, cyclone hopper 3 and vibrating screen 5 in sequence, and make extruder 2 vertically arranged below reactor 1;

[0062] b. Install the sealing member 1-2 at the bottom of the reactor 1, install the sealing top cover 1-3 and the stirring assembly of the reactor 1 in place, and connect the reactor 1 to the vacuum system, the heating system and the nitrogen pipeline respectively;

[0063] c. Add the required monomer materials and catalysts into the feeding port 1-4 on the sealed top cover 1-3 of the reaction kettle, and start the stirring paddle 1-8 to fully mix the materials;

[0064] d. Cover and seal the top cover 1-3, use the vacuum system to extract the air in the reactor 1 until the required vacuum degree is reached in the reactor 1, and at the same time, deliver nitrogen to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com