Functional edible film and preparation method thereof

A functional and modified technology, applied in the direction of sustainable manufacturing/processing, flexible coverings, flexible slender elements, etc., can solve food safety, poor stability of natural functional active factors, and inability to have broad-spectrum antibacterial properties at the same time Sex and other issues, to achieve the effect of simple preparation method, no toxic and side effects, and prolong shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

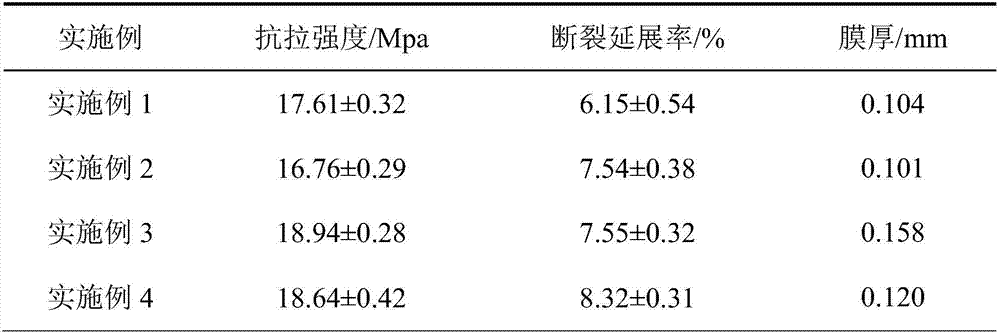

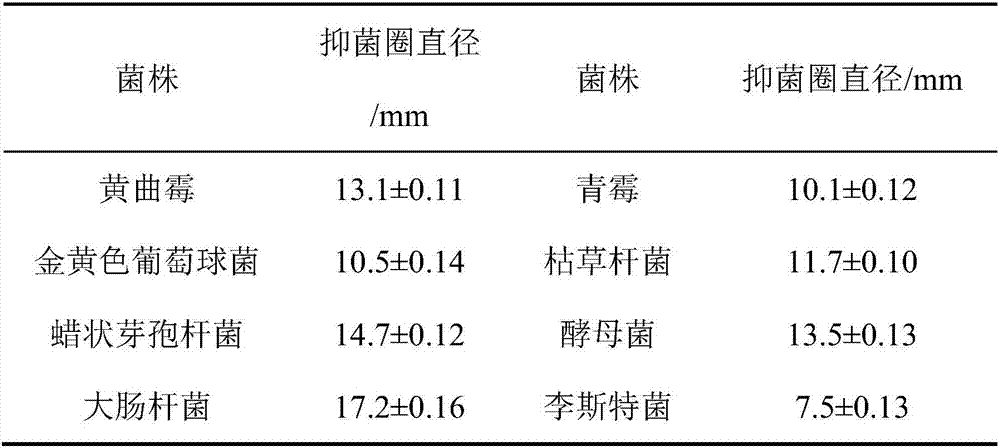

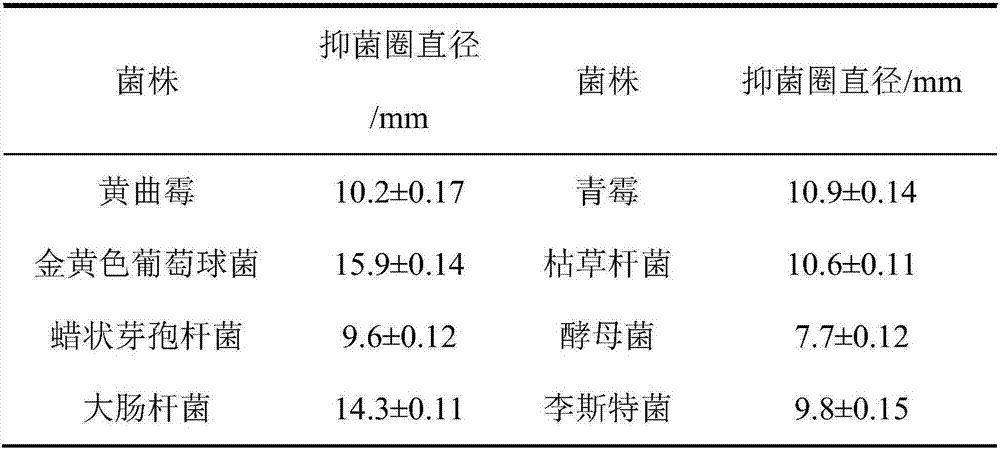

Examples

Embodiment 1

[0044] (1) Weigh 10g of cocoa butter, melt it at 50°C, then add 50mg of carnosic acid and fully dissolve it to obtain an oil phase;

[0045] (2) Take 100mL of deionized water and heat it to 50°C, add 0.20g of Tween80 and 0.30g of Span80 and mix thoroughly to obtain the aqueous phase;

[0046] (3) The volume ratio of the oil phase to the water phase is 1:10, the water phase is added to the oil phase and mixed, sheared at a high speed of 10kprm for 2min, then transferred to a high-pressure homogenizer, and homogenized 5 times at 30MPa to obtain SLN dispersion, after cooling to room temperature, refrigerate at 4°C;

[0047] (4) Divide the SLN dispersion in (3) into glass petri dishes for pre-freezing for 24 hours, transfer to a vacuum freeze dryer to dry for 24 hours to obtain SLN powder, and refrigerate at 4°C;

[0048] (5) Weigh 5g of glycerol, 20g of hydroxypropyl high amylose starch (dry basis) and 400mL of deionized water, mix well, transfer to a three-necked flask, and gel...

Embodiment 2

[0053] (1) Weigh 10g of cocoa butter, melt it at 50°C, then add 100mg of proanthocyanidins and fully dissolve to obtain the oil phase;

[0054] (2) Take 67mL of deionized water and heat it to 50°C, add 0.25g of Tween80 and 0.25g of Span80 and mix thoroughly to obtain the aqueous phase;

[0055] (3) According to the volume ratio of the oil phase and the water phase is 1.5:10, the water phase is added to the oil phase and mixed, sheared at a high speed of 12000prm for 2min, then transferred to a high-pressure homogenizer, and homogenized 5 times at 40MPa to obtain SLN dispersion, after cooling to room temperature, refrigerate at 4°C;

[0056] (4) Divide the SLN dispersion in (3) into glass petri dishes for pre-freezing for 24 hours, then transfer to a vacuum freeze dryer to dry for 24 hours to obtain SLN powder, and refrigerate at 4°C;

[0057] (5) Weigh 5g of glycerol, 20g of hydroxypropyl high amylose starch (dry basis) and 400mL of deionized water, mix well, transfer to a th...

Embodiment 3

[0062] (1) Weigh 20g of stearic acid and 5g of soybean lecithin, melt at 80°C, then add 200mg of carnosic acid and fully dissolve to obtain an oil phase;

[0063] (2) Take 125mL of deionized water and heat it to 80°C, add 0.75g of poloxamer 188 and mix thoroughly to obtain an aqueous phase;

[0064] (3) According to the volume ratio of the oil phase and the water phase is 2:10, add the water phase to the oil phase and mix, shear at a high speed of 15000r / min for 2min, then transfer to a high-pressure homogenizer, and homogenize 5 times at 50MPa , to obtain the SLN dispersion, cooled to room temperature and refrigerated at 4°C;

[0065] (4) Divide the SLN dispersion in (3) into glass petri dishes and pre-freeze for 36 hours, then transfer to a vacuum freeze dryer to dry for 24 hours to obtain SLN powder, and refrigerate at 4°C;

[0066] (5) Weigh 4.8g of glycerol, 24g of potato starch (dry basis) and 300mL of deionized water, mix well, transfer to a three-necked flask, and gel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com