Adhesive resin and preparation method and applications thereof

A technology for bonding resin and ethylene, which is applied in the direction of adhesives, adhesive types, grafted polymer adhesives, etc., can solve the problems of poor bonding durability, low cohesive force, and poor water resistance, and achieve bonding Strong durability, high bonding strength, and strong water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

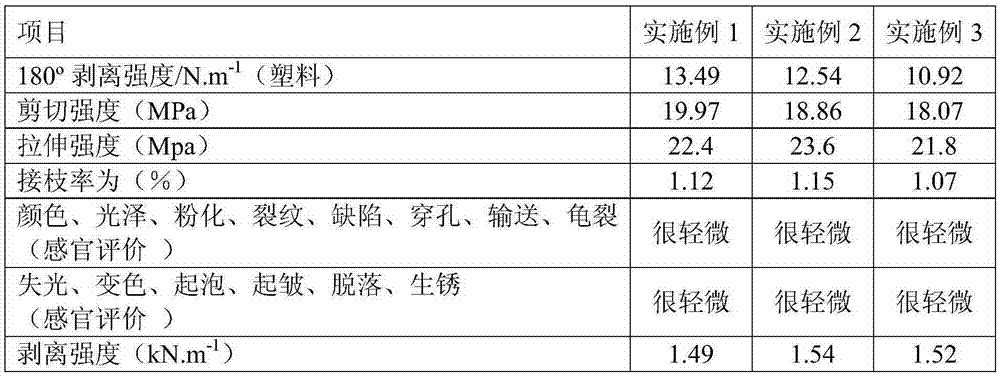

Examples

Embodiment 1

[0027] The content of each raw material component is as follows in the present embodiment:

[0028] 4 parts by weight of high-density polyethylene;

[0029] Ethylene-vinyl acetate copolymer 1.0 parts by weight;

[0030] 0.9 parts by weight of low-density polyethylene;

[0031] 0.45 parts by weight of 1,1-bis-(tert-butylperoxy)-3,3,5-trimethylcyclohexane;

[0032] 0.5 parts by weight of 3,3,6,6,9,9-hexamethyl-1,2,4,5-tetraoxocyclononane;

[0033] 0.55 parts by weight of 2,5-dimethyl-2,5-bis(benzoylperoxy)hexane;

[0034] 1 part by weight of maleic anhydride;

[0035] Wherein: the high-density polyethylene is purchased from Kunshan Aimed Plastic Technology Co., Ltd., the brand is 2911;

[0036] The ethylene-vinyl acetate copolymer is purchased from Suzhou Suyang Plastic Chemical Co., Ltd., and the trade mark is EVA150;

[0037] The low-density polyethylene is purchased from DuPont China Group Co., Ltd., and the brand name is 1F7B.

[0038] The specific preparation method ...

Embodiment 2

[0043] The content of each raw material component is as follows in the present embodiment:

[0044] 5 parts by weight of high-density polyethylene;

[0045] Ethylene-vinyl acetate copolymer 0.9 parts by weight;

[0046] 1.0 parts by weight of low-density polyethylene;

[0047] 0.55 parts by weight of 1,1-bis-(tert-butylperoxy)-3,3,5-trimethylcyclohexane;

[0048] 0.45 parts by weight of 3,3,6,6,9,9-hexamethyl-1,2,4,5-tetraoxocyclononane;

[0049] 0.5 parts by weight of 2,5-dimethyl-2,5-bis(benzoylperoxy)hexane;

[0050] 2 parts by weight of maleic anhydride;

[0051] Wherein: the high-density polyethylene is purchased from Kunshan Aimed Plastic Technology Co., Ltd., the brand is 2911;

[0052] The ethylene-vinyl acetate copolymer is purchased from Suzhou Suyang Plastic Chemical Co., Ltd., and the trade mark is EVA150;

[0053] The low-density polyethylene is purchased from DuPont China Group Co., Ltd., and the brand name is 1F7B.

[0054] The specific preparation method...

Embodiment 3

[0059] The content of each raw material component is as follows in the present embodiment:

[0060] 6 parts by weight of high-density polyethylene;

[0061] Ethylene-vinyl acetate copolymer 1.1 parts by weight;

[0062] 1.1 parts by weight of low-density polyethylene;

[0063] 0.5 parts by weight of 1,1-bis-(tert-butylperoxy)-3,3,5-trimethylcyclohexane;

[0064] 0.55 parts by weight of 3,3,6,6,9,9-hexamethyl-1,2,4,5-tetraoxacyclononane;

[0065] 0.45 parts by weight of 2,5-dimethyl-2,5-bis(benzoylperoxy)hexane;

[0066] 3 parts by weight of maleic anhydride;

[0067] Wherein: the high-density polyethylene is purchased from Kunshan Aimed Plastic Technology Co., Ltd., the brand is 2911;

[0068] The ethylene-vinyl acetate copolymer is purchased from Suzhou Suyang Plastic Chemical Co., Ltd., and the trade mark is EVA150;

[0069] The low-density polyethylene is purchased from DuPont China Group Co., Ltd., and the brand name is 1F7B.

[0070] The specific preparation method i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com