Handmade soap and preparation method thereof

A technology of handmade soap and palm oil, applied in chemical instruments and methods, skin care preparations, alkali soap/ammonium soap composition, etc., can solve problems such as capillary blockage and skin damage, achieve super decontamination, and reduce production costs The effect of low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

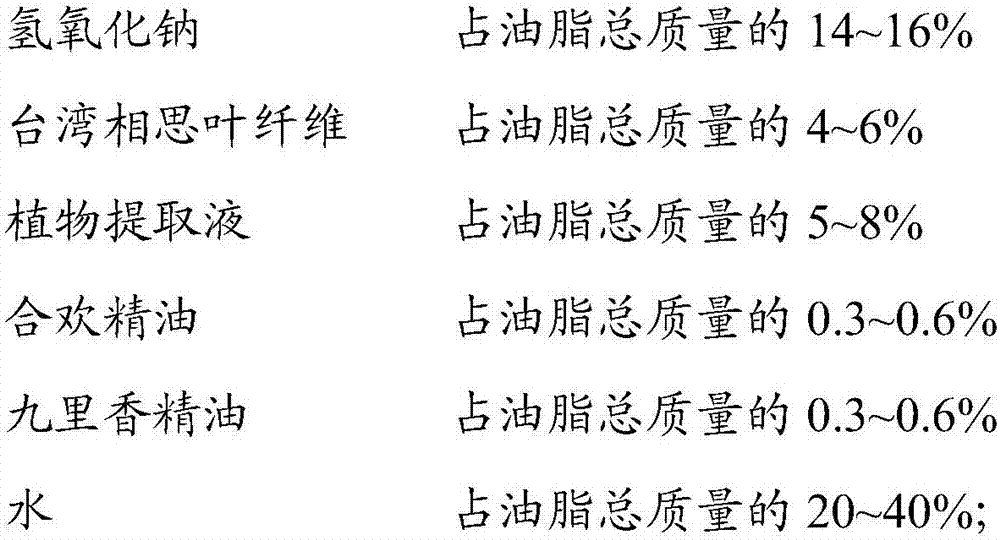

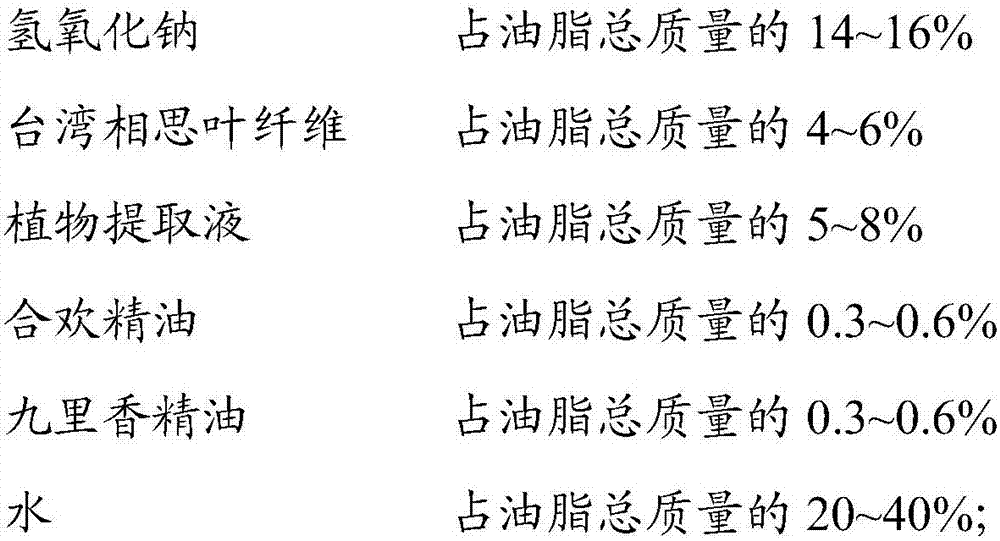

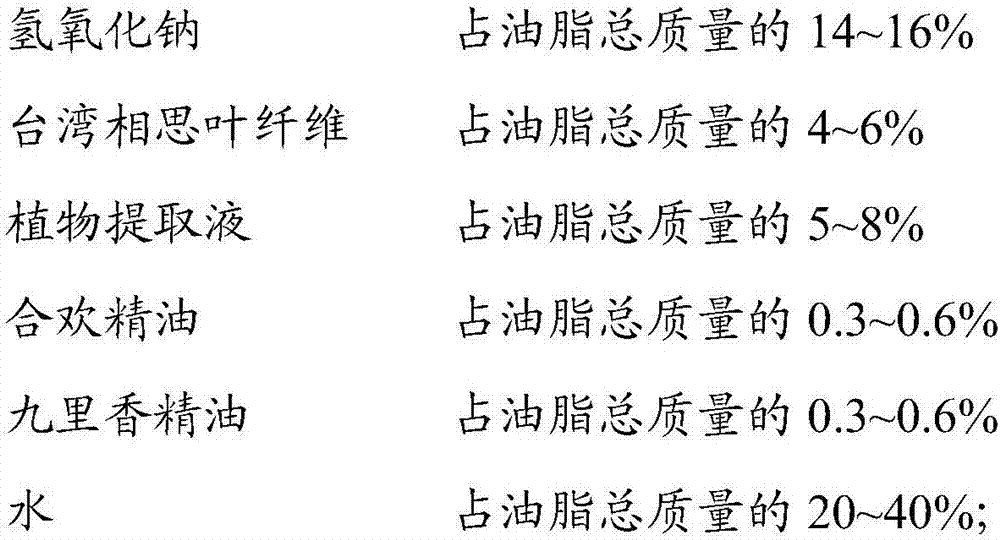

Method used

Image

Examples

preparation example Construction

[0038] A preparation method of handmade soap, comprising the following steps:

[0039] (1) Weigh sodium hydroxide according to the formula ratio, add plant extract and water to dissolve, cool to 50-55°C, and obtain mixed lye, wherein, the plant extract is Erythrina leaf extract, Clover One or more mixtures of needle grass extract or sheep's hoof flower extract;

[0040] (2) mixing palm oil, olive oil and coconut oil according to the formula ratio, heating to 40-50°C to obtain mixed oil;

[0041] (3) Slowly pour the mixed lye in the step (1) into the mixed oil in the step (2) under stirring, and continue to stir until there is no oil-water separation phenomenon, and obtain the mixed solution after the saponification reaction;

[0042] (4) After the mixed solution after the saponification reaction in step (3) is cooled to room temperature, slowly add Taiwan acacia leaf fiber, Albizia Julibrissin quintessence oil, and Gourilla quince essential oil, and stir to obtain handmade so...

Embodiment 1

[0050] A preparation method of handmade soap, comprising the following steps:

[0051](1) Weigh 40g of sodium hydroxide according to the proportion of the formula, add 15mL of plant extract and 75mL of water to dissolve, cool to 50°C, and obtain a mixed lye, wherein the plant extract is 5mL of Erythrina leaf extract and 3 leaf ghost 10mL mixture of needle grass extract;

[0052] (2) 80g of palm oil, 100g of olive oil and 80g of coconut oil are mixed, heated to 50°C to obtain mixed oil;

[0053] (3) Slowly pour the mixed lye in the step (1) into the mixed oil in the step (2) under stirring, and continue to stir until there is no oil-water separation phenomenon, and obtain the mixed solution after the saponification reaction;

[0054] (4) After the mixed solution after the saponification reaction in step (3) is cooled to room temperature, slowly add 12g of Taiwan acacia leaf fiber, 1mL of Albizia Julibrissin essential oil, and 1mL of Jiulixiang essential oil, and stir to obtain...

Embodiment 2

[0062] A preparation method of handmade soap, comprising the following steps:

[0063] (1) Weigh 45g of sodium hydroxide according to the proportion of the formula, add 20mL of plant extract and 85mL of water to dissolve, cool to 50°C, and obtain a mixed lye, wherein, the plant extract is 6mL of Erythrina leaf extract, 3 leaf ghost A mixture of 8mL of needlewort extract and 6mL of S. chinensis extract;

[0064] (2) 100g of palm oil, 120g of olive oil and 100g of coconut oil are mixed, heated to 50°C to obtain mixed oil;

[0065] (3) Slowly pour the mixed lye in the step (1) into the mixed oil in the step (2) under stirring, and continue to stir until there is no oil-water separation phenomenon, and obtain the mixed solution after the saponification reaction;

[0066] (4) After the mixed solution after the saponification reaction in step (3) is cooled to room temperature, slowly add 13g of Taiwan Acacia leaf fiber, 1.5mL of Albizia Julibrissin essential oil and 1mL of Guriba e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com