Method for improving stability of monatomic catalyst for catalytic combustion of VOCs

A catalytic combustion and catalyst technology, applied in combustion methods, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of single-atom catalyst stability and sintering resistance limitations, and achieve conditions conducive to industrial application and preparation. Mild, life-extending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

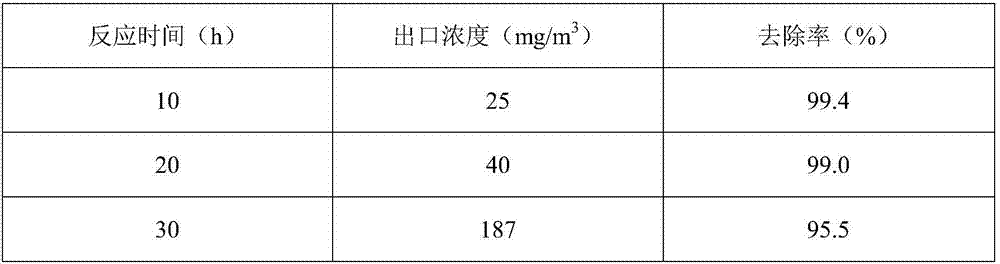

Embodiment 1

[0038] (1) Prepare tris buffer solution containing dopamine. Take 1.0 g of Tris, add 100 ml of water, stir to dissolve, and then adjust the pH value to 8.0 with 5 mol / L hydrochloric acid solution to obtain a Tris buffer solution with a concentration of 1 wt%. Take 50 mL of the solution and add 5.5 g of dopamine to prepare a dopamine-containing Tris buffer solution with a concentration of 10 wt%.

[0039](2) Preparation of single-atom catalyst-polydopamine. Get the single-atom catalyst Pt of 1g, loading capacity is 0.02wt% (active component and catalyst total mass ratio), catalyst support is Al2O3, adding the tris buffer solution containing dopamine that concentration is 10wt% , the mass ratio of catalyst to solution is 1:4. Stir magnetically for 24 hours, then centrifuge the suspension to obtain a precipitate, then wash the precipitate with deionized water for 3 times, and then wash with ethanol for 3 times; vacuum-dry the precipitate from which impurities have been removed ...

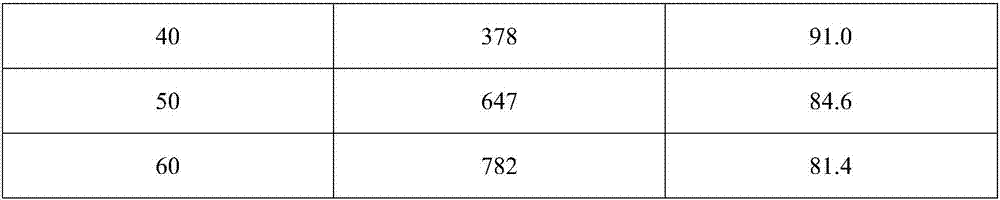

Embodiment 2

[0050] (1) Preparation of tris buffer containing dopamine. Take 2.0 g of Tris, add 100 ml of water, stir to dissolve, and then adjust the pH value to 8.0 with 5 mol / L hydrochloric acid solution to obtain a Tris buffer solution with a concentration of 2 wt%. Take 50 mL of the solution and add 4.3 g of dopamine to prepare a tris buffer solution containing dopamine with a concentration of 8 wt%.

[0051] (2) Preparation of single-atom catalyst-polydopamine. Get 1g of single-atom catalyst Pd, loading capacity is 0.01wt% (active component and catalyst total mass ratio), catalyst carrier is ferric oxide, adding concentration is the Tris buffer solution containing dopamine of 8wt% , the mass ratio of catalyst to solution is 1:5. Magnetically stirred for 24 hours, then the suspension was centrifuged to obtain a precipitate, and then the precipitate was washed with deionized water for 3 times, and then washed with ethanol for 3 times; the precipitate from which impurities were remove...

Embodiment 3

[0061] (1) Preparation of tris buffer containing dopamine. Take 2.6 g of Tris, add 100 ml of water, stir to dissolve, and then adjust the pH value to 8.0 with 5 mol / L hydrochloric acid solution to obtain a Tris buffer solution with a concentration of 2.5 wt%. Take 50 mL of the solution and add 3.8 g of dopamine to prepare a dopamine-containing Tris buffer solution with a concentration of 7 wt%.

[0062] (2) Preparation of single-atom catalyst-polydopamine. Get 1g of single-atom catalyst Au, loading capacity is 0.1wt% (active component and catalyst total mass ratio), catalyst carrier is titanium dioxide, adding the tris buffer solution containing dopamine that concentration is 7wt%, catalyst and The mass ratio of the solution is 1:6. Magnetically stirred for 24 hours, then the suspension was centrifuged to obtain a precipitate, and then the precipitate was washed 3 times with deionized water, and then washed 3 times with ethanol; the precipitate from which impurities were rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com