Resin Flux Solder Paste and Mounting Structure

A technology of flux and resin, which is applied in the field of resin flux solder paste and mounting structures, can solve the problems of rising costs and achieve the effects of improving drop resistance, improving melting, and suppressing reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0066]

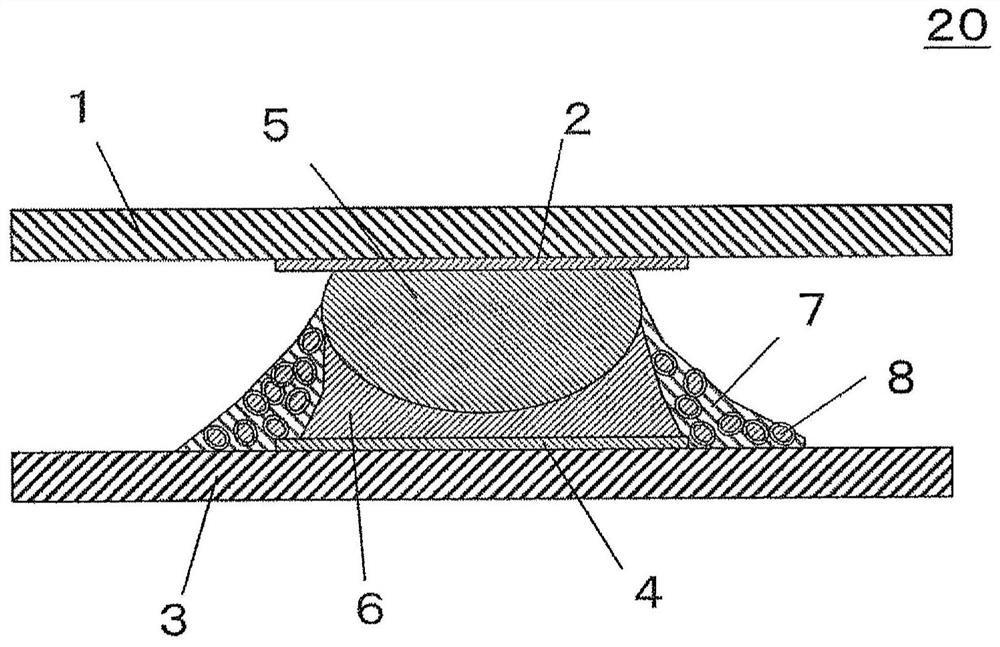

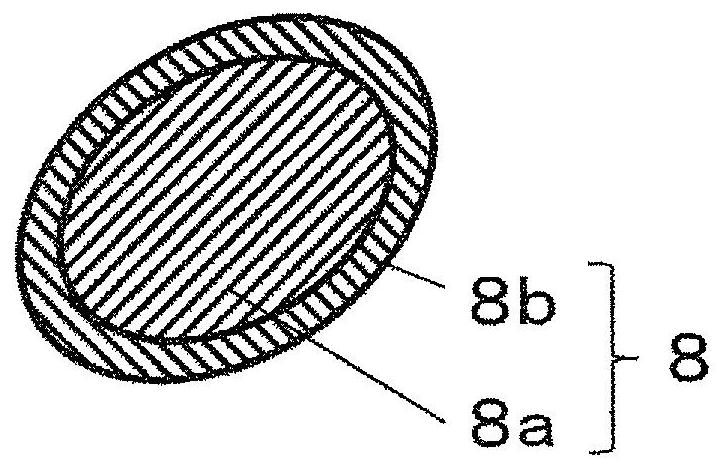

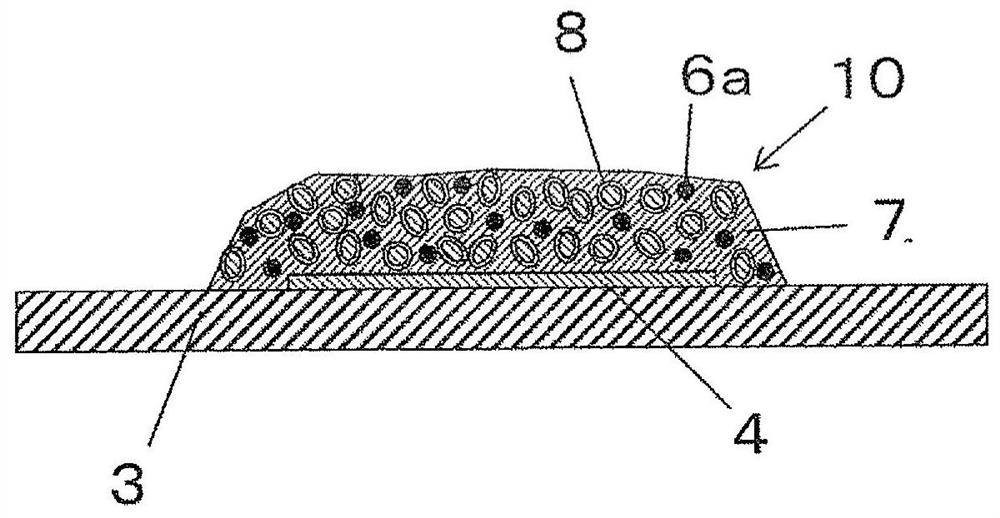

[0067] The resin flux solder paste according to Embodiment 1 includes non-resin-based powder including solder powder and inorganic powder, and flux including a first epoxy resin, a curing agent, and an organic acid. The non-resin powder is 30 to 90 wt% of the whole. On the other hand, 10 to 70 wt% of the remaining portion is composed of flux including the first epoxy resin, curing agent, and organic acid. The surface of the inorganic powder is covered with an organic resin. The inorganic powder can be, for example, silicon dioxide. The organic resin may be, for example, a second epoxy resin.

[0068] According to this resin flux solder paste, when used for solder bonding of electronic components to circuit boards, since it contains inorganic powder, it is possible to reinforce the reinforcing part more firmly with the resin of the solder joint part without using an underfill material. . Therefore, the drop resistance of the attachment structure can be improved. ...

Embodiment 2

[0151] Example 2 was the same as Example 1, and the ratio of the non-resin powder was 90 wt%. In addition, as fused silica, (a) silica having a particle diameter of 1 μm was used. The ratio of the solder powder to the silica was 5% of the silica with respect to the whole non-resin powder.

Embodiment 3

[0152] The ratio of the non-resin powder of Example 3 was 70 wt%. In addition, as fused silica, silica having a particle diameter of (c) of 11 μm was used. The ratio of the solder powder to the silica was compounded at 40% of the silica relative to the entire non-resin powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com