Method for preparing zinc-rich calcium magnesium nitrate fertilizer by utilizing by-product calcium nitrate of phosphorus nitrate fertilizer

A technology of calcium and magnesium nitrate fertilizer and nitrophosphate fertilizer, which is applied in the field of fertilizer preparation, can solve the problems of increasing crop production cost, insufficient calcium utilization rate, large equipment load, etc., and achieves increasing appearance color and gloss, improving quality and output, and reducing raw materials. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

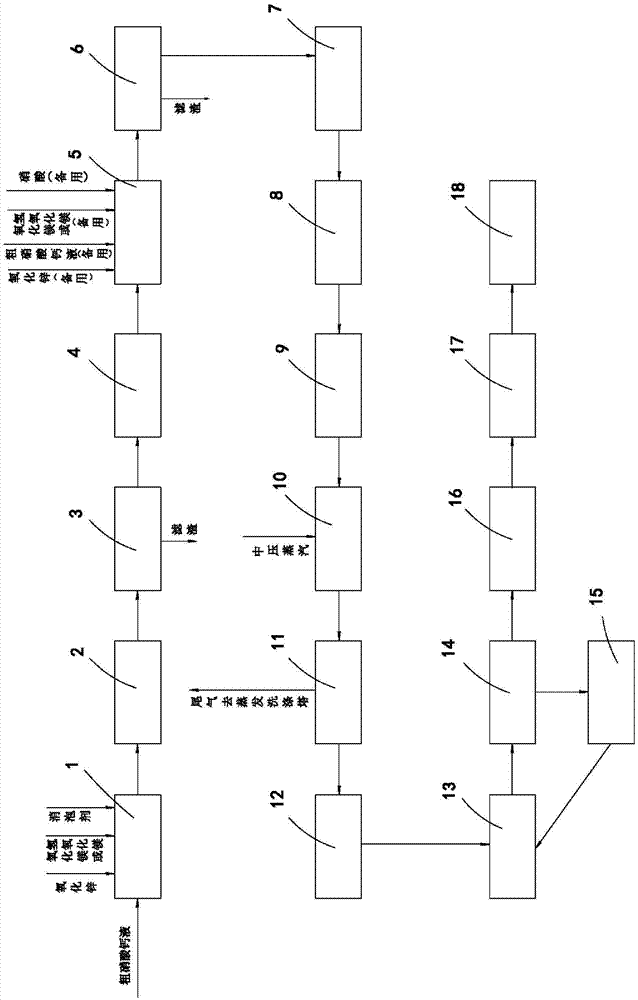

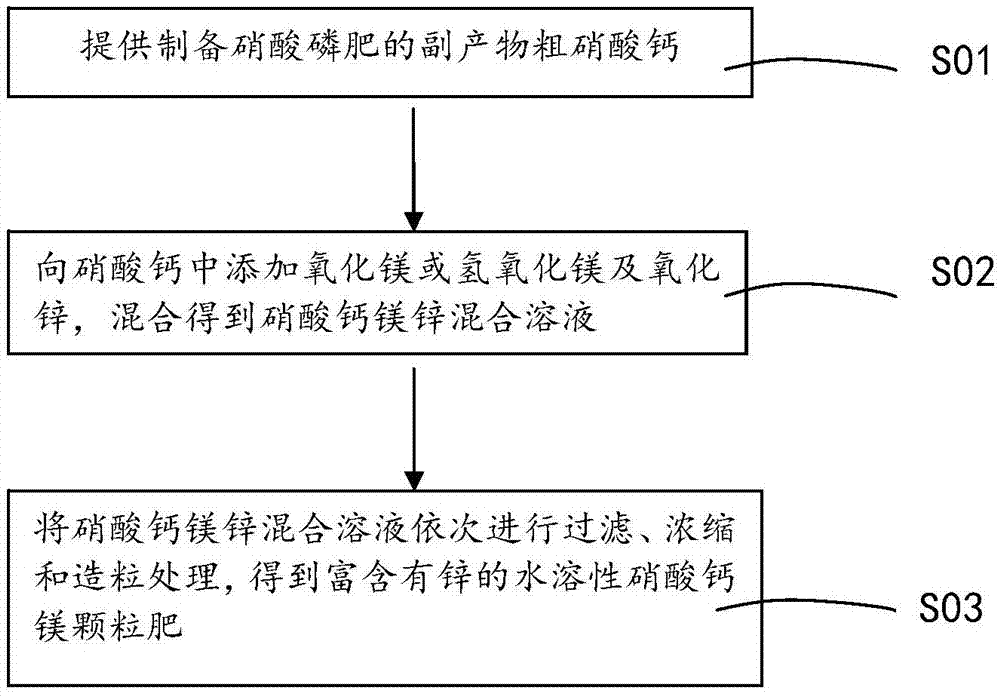

[0054] A kind of method that utilizes the crude calcium nitrate byproduct of nitrophosphate fertilizer to prepare the calcium nitrate magnesium fertilizer that the calcium weight percentage content is 16.8%, the magnesium weight percentage content is 2.2%, and the zinc weight percentage content is 0.02%, comprises the following steps, as figure 2 Shown:

[0055] S11. Provide crude calcium nitrate as a by-product for preparing nitrophosphate fertilizer: freeze and crystallize the crude calcium nitrate of nitrophosphate fertilizer, filter and separate it to the crude calcium nitrate buffer tank, and transport it to the neutralization reaction tank 1 by the crude calcium nitrate pump;

[0056] S12. Add magnesium oxide or magnesium hydroxide and zinc oxide to the calcium nitrate, and mix to obtain a mixed solution of calcium nitrate, magnesium and zinc, which specifically includes the following steps:

[0057] S121. According to the content of calcium in the thick calcium nitrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com