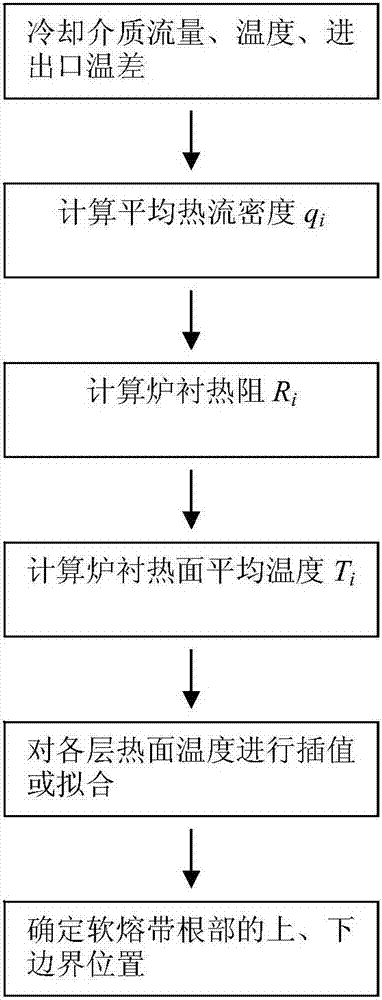

Online blast furnace soft melting zone root position monitoring method

A technology of reflow belt, blast furnace, applied in the direction of blast furnace, blast furnace detail, furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0176] The following examples are used to illustrate the present invention, but do not limit the scope of application of the present invention.

[0177] For a more reasonable description of the realization of the present invention, the following will be combined with the accompanying drawings and a volume of 2650m 3 The actual production parameters of the blast furnace at a certain moment will further describe the realization process of the present invention.

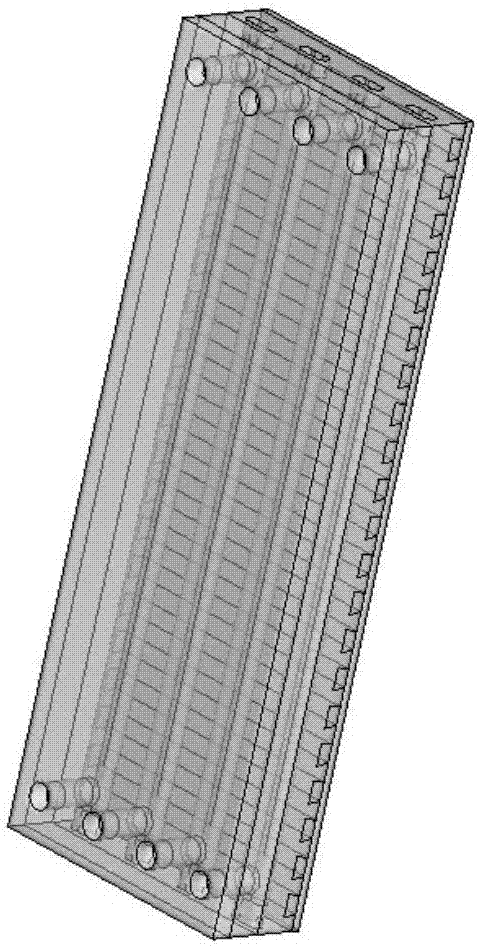

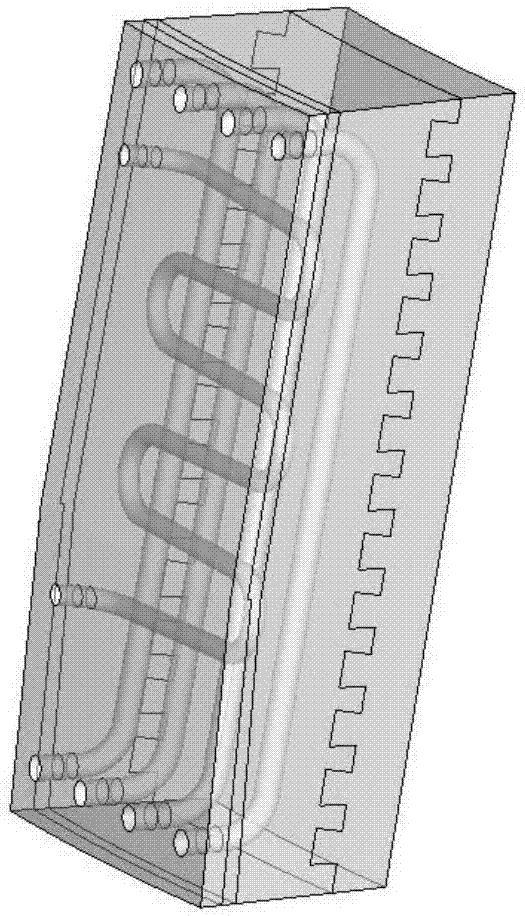

[0178] Figure 2 is a schematic diagram of various linings and cooling staves used in the blast furnace. The blast furnace is equipped with 15 floors, and the 6th to 8th floor linings use copper cooling staves, as shown in Figure 2 (1); the 9th to 11th floors of furnace linings use ductile iron brick-inlaid cooling walls with serpentine tubes, as shown in Figure 2 ( As shown in 2), the 12th to 14th layers of furnace lining use ordinary ductile iron brick-inlaid cooling walls, as shown in Figure 2 (3); the 15th layer of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com