Organic matter vanadium removal mud solid-liquid separation device and separation method

A technology for solid-liquid separation and organic matter, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve problems such as high equipment requirements, clogging of nozzles, complex process flow, etc., and achieve high separation efficiency, low energy consumption, and process Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

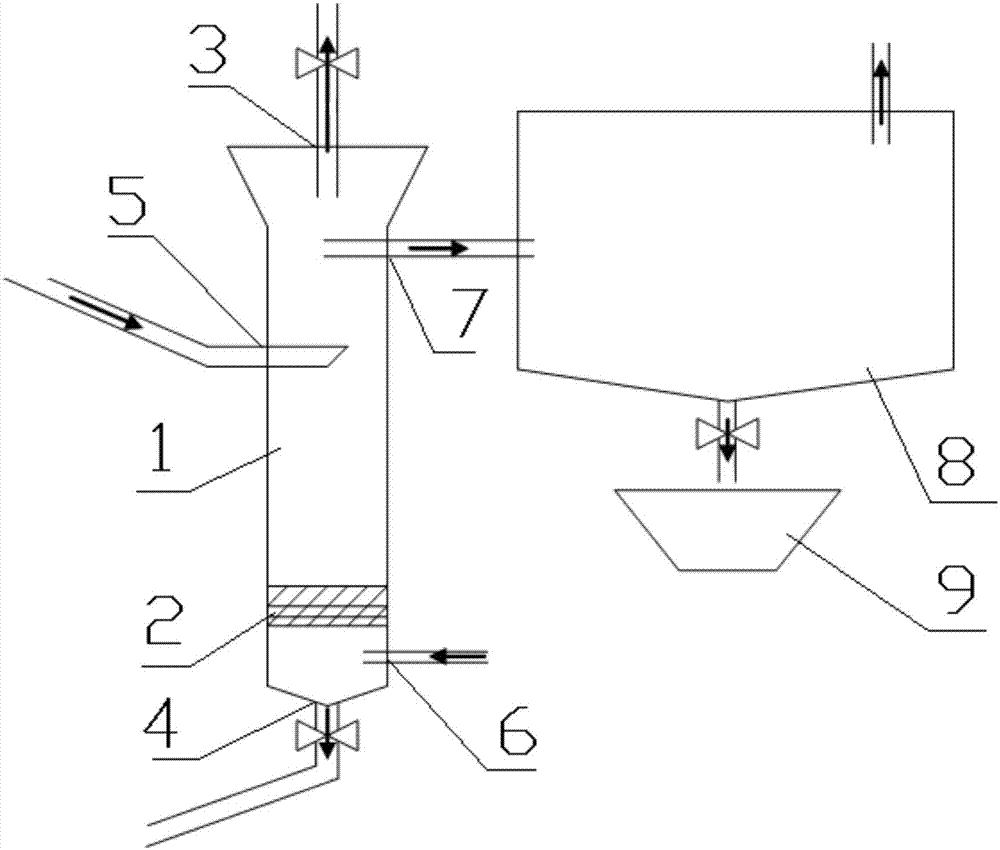

[0025] Example 1: Solid-liquid separation of vanadium removal slurry for organic matter in the laboratory

[0026] Main equipment: drying furnace size φ200mm×1000mm, amplification room 1000mm×1000mm×1500mm, processing 20kg of vanadium removal mud per hour. The implementation steps are: A. Through the slurry pump, 20kg of organic vanadium removal slurry is input into the drying furnace 1 through the slurry inlet 5, and the valve of the bottom slurry outlet 4 is opened, and the filtrate is sent out for 4 minutes to 6 minutes; B. Close the slurry outlet 4 , the valves of mud inlet 5 and hot gas outlet 7, open the valves of condenser interface 3 and hot gas inlet 6, and the hot gas inlet 6 is fed with heated inert gas. / s, until there is no condensate in the condensation place, the time is generally 30min to 40min; C, close the valve of the condenser interface 3, open the valve of the hot gas outlet 7, open the valve of the tail gas outlet of the amplification chamber 8, and incre...

example 2

[0027] Example 2: Solid-liquid separation treatment of 2t / h organic vanadium removal mud

[0028] Main equipment: drying furnace size φ1500mm×2000mm, amplification chamber 3000mm×3000mm×5000mm, processing 2000kg of organic vanadium removal mud per hour. The implementation steps are: A. Through the slurry pump, 2000kg of organic vanadium removal slurry is input into the drying furnace 1 through the slurry inlet 5, and the valve of the bottom slurry outlet 4 is opened, and the filtrate is sent out for 8 minutes to 12 minutes; B. Close the slurry outlet 4 , the valves of mud inlet 5 and hot gas outlet 7, open the valves of condenser interface 3 and hot gas inlet 6, and the hot gas inlet 6 is fed with heated inert gas. / s, until there is no condensate in the condensation place, the time is generally 40min to 50min; C. Close the valve of the condenser interface 3, open the valve of the hot gas outlet 7, open the valve of the exhaust gas outlet of the amplification chamber 8, and in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com