Device for hydrothermal preparation of powder materials

A technology of powder materials and hydrothermal method, which is applied in chemical instruments and methods, chemical/physical/physical chemical processes of energy application, chemical/physical/physical chemical fixed reactors, etc., can solve the problem that microwave heating cannot be guaranteed uniformly The degree of radiation is not evenly distributed in the main space of the container, etc., so as to improve the quality of powder products, shorten the synthesis time, and improve the production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

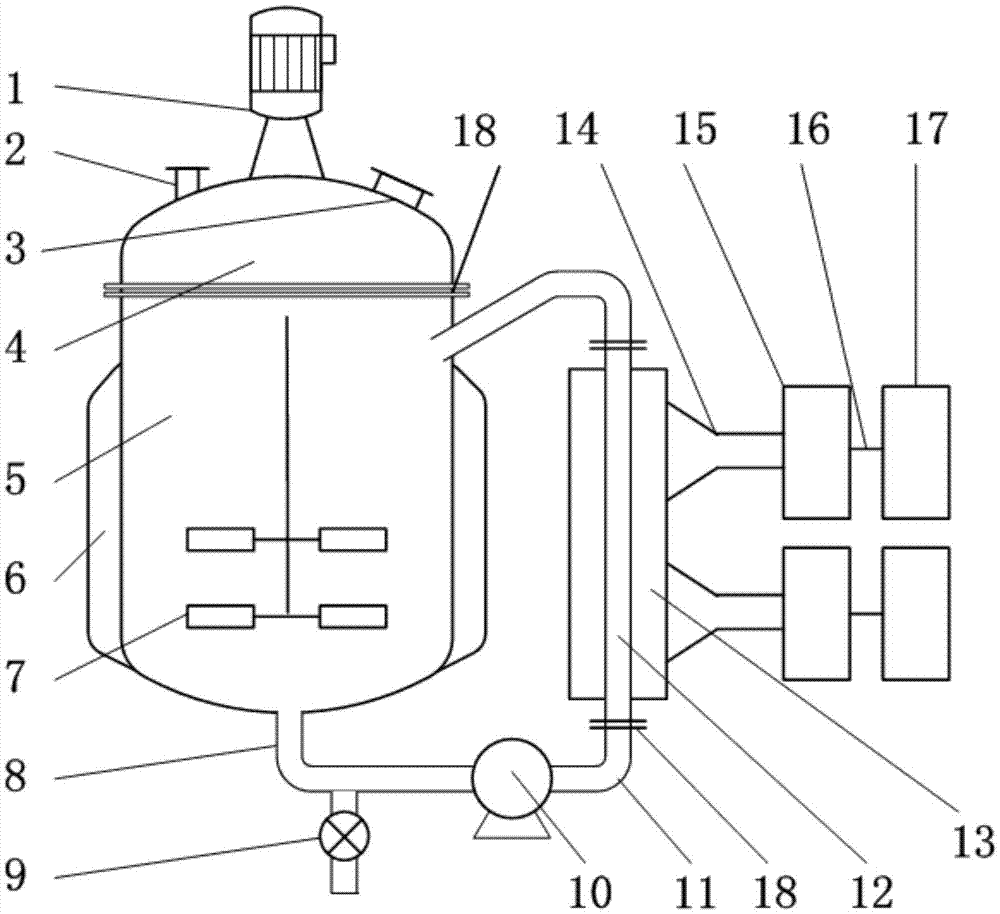

[0033] see figure 1 As shown, the device for preparing powder materials by the hydrothermal method of the present invention includes a tank-type stirred reactor composed of a top cover 4 and a kettle body 5, a circulation system and a microwave heating system, and the microwave heating system includes a microwave cavity, a microwave generator 15 And microwave power supply and control system 17. The top cover 4 and the kettle body 5 are connected by a flange 18. The top cover 4 is provided with a stirring motor 1, a gas discharge port 2 and a feed port 3. The stirring motor 1 is arranged in the middle of the top cover 4 and its bottom is connected with an extension Into the stirring paddle 7 in the kettle body 5, the outer wall of the middle and lower part of the kettle body 5 is provided with an insulating layer 6, the bottom of the kettle body 5 is connected with the inlet end of the circulation pump 10 through the first circulation pipeline 8, and the first circulation pipel...

Embodiment 2

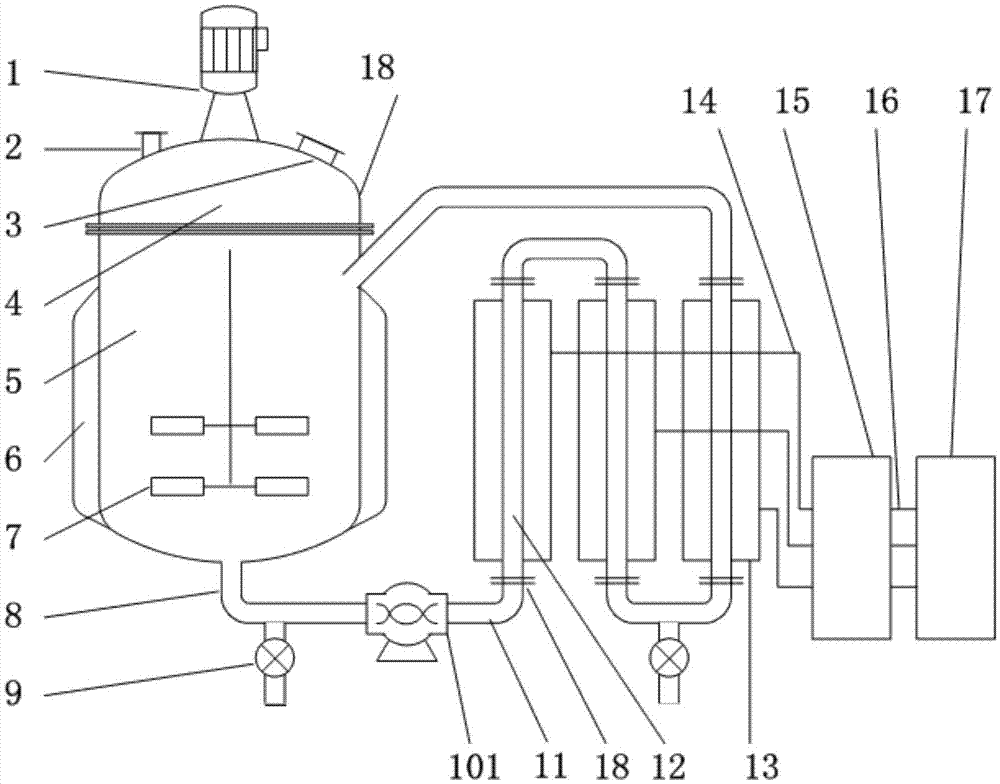

[0037] see figure 2 As shown, on the basis of the device in Example 1, the microwave-heated inner tube 12 is set as three sections of tubes 121 arranged vertically and parallelly in series through metal pipes, and each section of tubes 121 is provided with an independent microwave-heated metal cavity 13. According to the needs of heating power, more sections of tubes can be set; the outer wall of the middle and lower part of the kettle body 5 is provided with an insulation layer 6, and the circulation pump 10 is replaced by a homogeneous pump 101, which can convert the The material of the block is evenly dispersed and then input into the subsequent microwave heating inner tube 12.

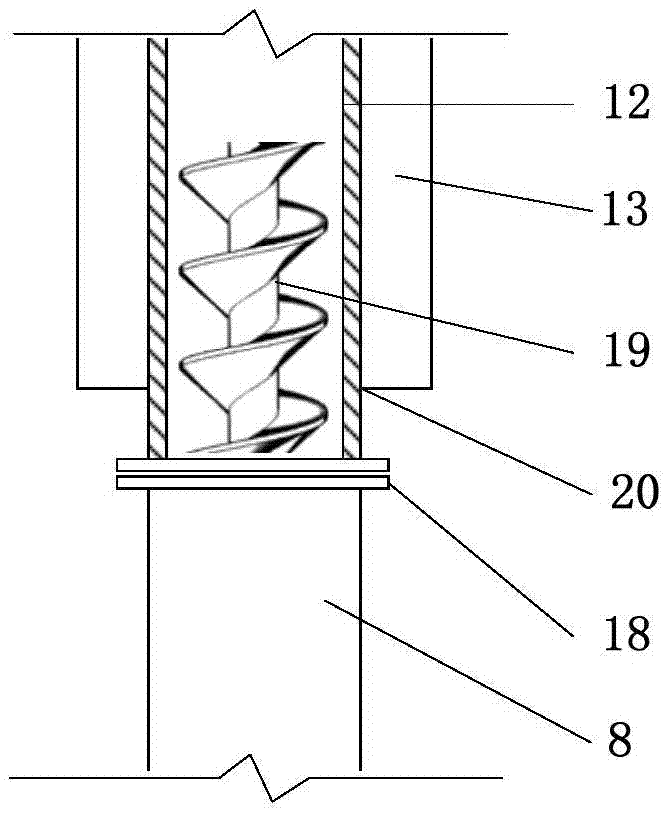

[0038] see image 3 As shown, the inlet end of the array tube 121 is provided with a helical member 19 , and the helical member 19 is 1 / 3 of the length of the array tube 121 .

[0039] Reaction material is with embodiment 1, and tank type stirred reactor is 1m 3 1. The length of the single-sect...

Embodiment 3

[0041] The device described in Example 2 was used to hydrothermally synthesize Y zeolite. The reactor size was 150 L. The length of the single-stage tubes 121 in the microwave cavity was 1.6 m, the inner diameter of the tubes 121 was 6 cm, and the maximum power of each single-stage microwave feeding was 5 kW. The reaction materials are water glass, aluminum sulfate, sodium metaaluminate and deionized water, according to the conventional formula and mixing sequence, the preparation composition is SiO 2 :Al 2 o 3 : Na 2 O: H 2 The molar ratio of O is 1:0.07:1.1:30 silica-alumina gel directing agent, and then the directing agent, silicon source, aluminum source and water are composed of SiO 2 : 0.1Al 2 o 3 : 0.9Na 2 O: 65H 2 The molar ratio of O is 1:0.1:0.9:65 for mixing and beating, turn on the homogeneous pump 101 to further mix evenly, turn on microwave heating, heat up to 100°C, cool down after constant temperature crystallization for 5 hours, and obtain the crystalli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com