Cocatalyst for reducing FCC (fluid catalytic cracking) regeneration flue gas pollutant discharge and application thereof

A pollutant emission and co-catalyst technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, heterogeneous catalyst chemical elements, etc., can solve the problem of not achieving efficient removal of SOx

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

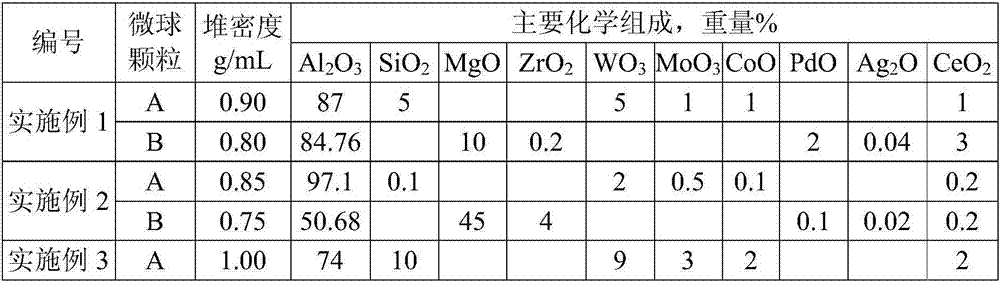

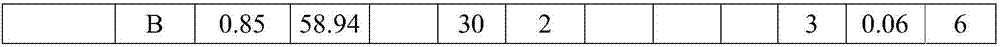

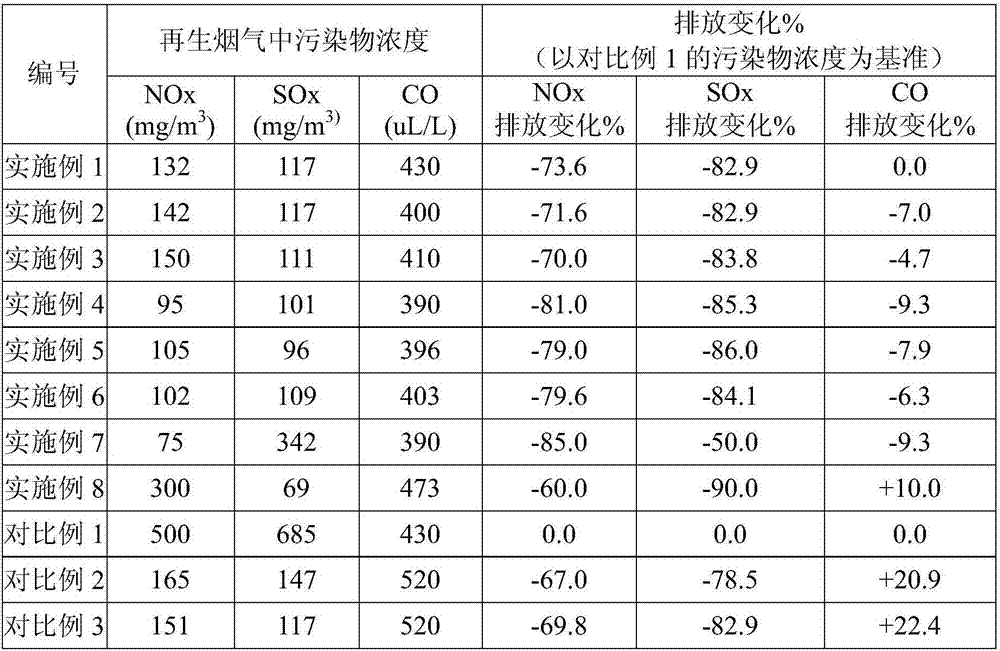

Embodiment 1

[0034] This embodiment provides a co-catalyst for reducing the emission of atmospheric pollutants such as NOx, SOx and CO in the regeneration flue gas. The co-catalyst includes microsphere particles A and microsphere particles B.

[0035] Wherein, microsphere particle A is prepared by the following steps:

[0036] Add deionized water into the stirring tank, then add 1.576 kg of pseudo-boehmite for beating, control the solid content of the slurry to about 12%, and beat for about 30 minutes; add hydrochloric acid solution, control the pH of the slurry to 1.2-2.0, and beat for about 60 minutes ;Continue to add 0.097 kg of kaolin into the stirring tank, beating for about 60 minutes; heat up to 60-80°C, let it stand for aging for about 120 minutes and continue stirring for 30 minutes, and then pump the colloidal material after beating into the spray drying system , to obtain a microsphere particle carrier, the microsphere particle carrier was calcined at 700° C. for 120 minutes to ...

Embodiment 2

[0045] This embodiment provides a co-catalyst for reducing the emission of atmospheric pollutants such as NOx, SOx and CO in the regeneration flue gas. The co-catalyst includes microsphere particles A and microsphere particles B.

[0046] Wherein, microsphere particle A is prepared by the following steps:

[0047] Add deionized water into the stirring tank, then add 1.665 kg of pseudo-boehmite for beating, control the solid content of the slurry to about 12%, and beat for about 30 minutes; add hydrochloric acid solution, control the pH of the slurry to 1.2-2.0, and beat for about 60 minutes ;Continue to add 0.002 kg of kaolin into the stirring tank, beating for about 60 minutes; heat up to 60-80°C, let it stand for aging for about 120 minutes and continue stirring for 30 minutes, and then pump the colloidal material after beating into the spray drying system , to obtain a microsphere particle carrier, the microsphere particle carrier was calcined at 700° C. for 120 minutes to ...

Embodiment 3

[0056] This embodiment provides a co-catalyst for reducing the emission of atmospheric pollutants such as NOx, SOx and CO in the regeneration flue gas. The co-catalyst includes microsphere particles A and microsphere particles B.

[0057] Wherein, microsphere particle A is prepared by the following steps:

[0058] Add deionized water into the stirred tank, then add 1.468 kg of pseudo-boehmite for beating, control the solid content of the slurry to about 12%, and beat for about 30 minutes; add hydrochloric acid solution, control the pH of the slurry to 1.2-2.0, and beat for about 60 minutes ;Continue to add 0.213 kg of kaolin into the stirring tank, beat for about 60 minutes; heat up to 60-80°C, let it stand for aging for about 120 minutes and continue to stir for 30 minutes, then pump the colloidal material after beating into the spray drying system , to obtain a microsphere particle carrier, the microsphere particle carrier was calcined at 700° C. for 120 minutes to obtain 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com