Method for preparing corrosion-resistance surface of bearing by laser texturing

A micro-modeling and corrosion-resistant technology, applied in laser welding equipment, bearings, bearing components, etc., can solve the problems of bearing self-lubricating performance, anti-friction and wear resistance and corrosion resistance that cannot meet the needs of industrialization, so as to improve the adaptability The ability to work in harsh environments, ensure the overall mechanical strength, improve the effect of anti-friction, wear resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing a corrosion-resistant surface of a bearing by laser micromodeling in this embodiment includes the following steps:

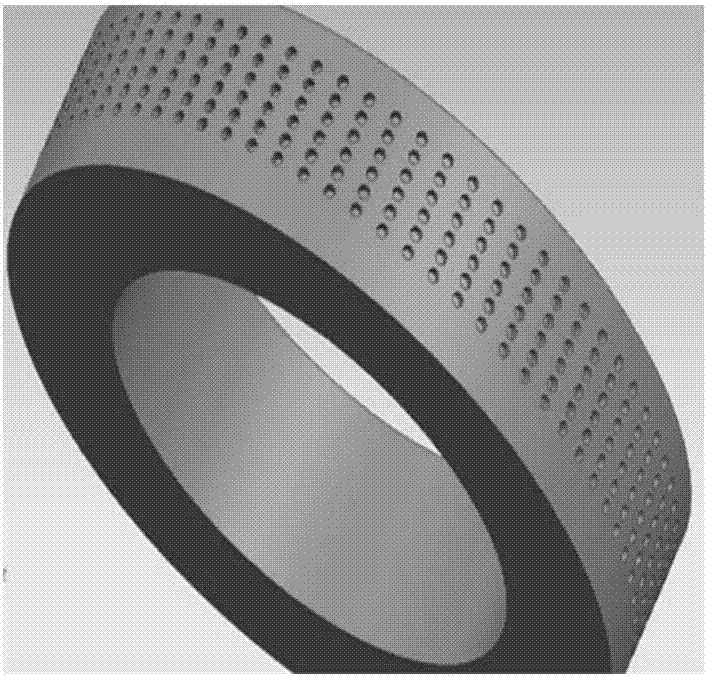

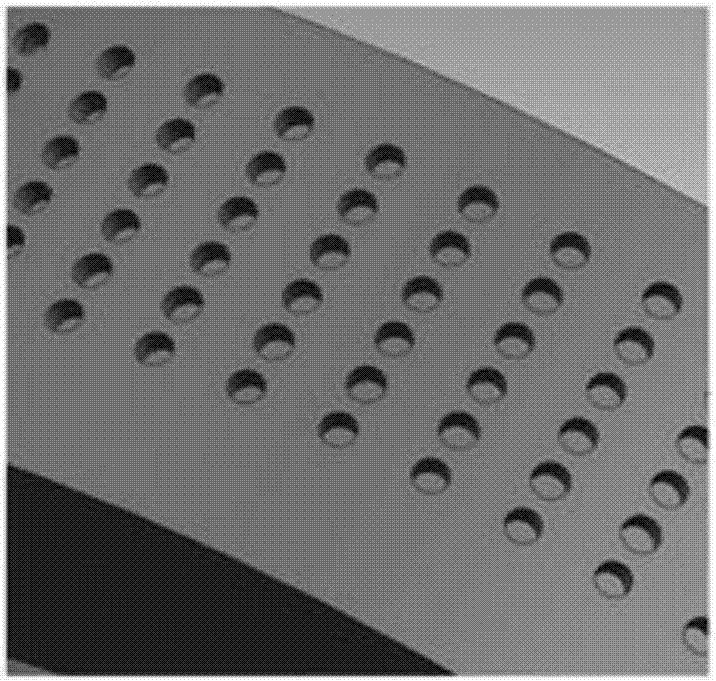

[0036] (1) Laser micro-modeling, using an infrared laser marking machine (DL-TG-IRF-30) to process a micro-pit structure on the outer surface of the inner ring of the rolling bearing with brass H62 as the base material, and the laser wavelength used is 1064nm , the laser output power is 20W, the laser frequency is 20kHz, the pulse width is 100ns, the diameter of the processed micro-pit is 60 μm, the depth is 20 μm, the distance between the two pits is 150 μm, and the area occupancy rate of the micro-pit is 20%;

[0037] (2) After-treatment of the bearing surface, the bearing samples after laser processing were polished with 3000# and 7000# sandpaper to remove surface burrs, and ultrasonically cleaned to obtain clean samples;

[0038] (3) Surface modification, immerse the bearing sample in a stearic acid ethanol solution with a mass pe...

Embodiment 2

[0043] A method for preparing a corrosion-resistant surface of a bearing by laser micromodeling in this embodiment includes the following steps:

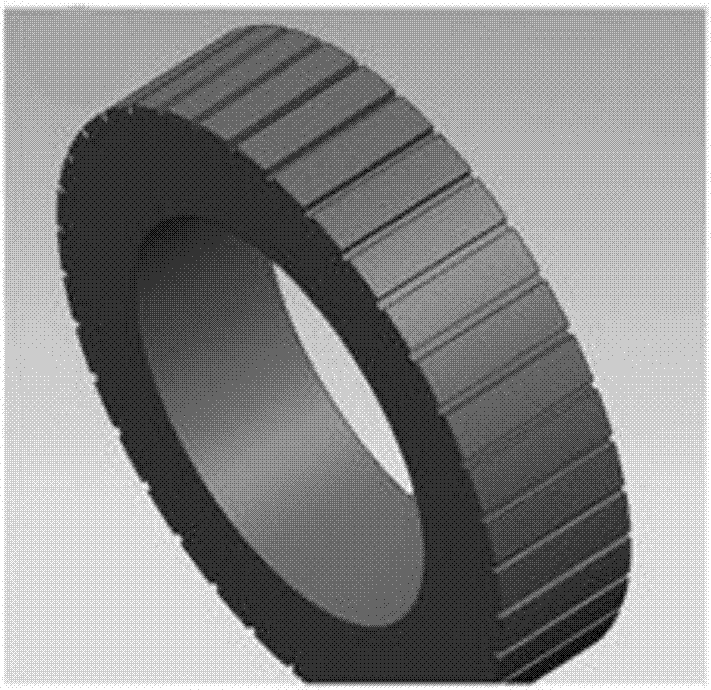

[0044] (1) Laser micro-modeling, using an infrared laser marking machine (DL-TG-IRF-30) to process a micro-groove structure on the working surface of the thrust bearing seat ring with 304 stainless steel as the base material, the laser wavelength used is 1064nm, The laser output power is 20W, the laser frequency is 20kHz, and the pulse width is 100ns. The width of the processed micro-groove is 80μm, the depth is 20μm, and the distance between the two grooves is 300μm.

[0045] (2) After-treatment of the bearing surface, the bearing samples after laser processing were polished with 3000# and 7000# sandpaper to remove surface burrs, and ultrasonically cleaned to obtain clean samples;

[0046] (3) Surface modification, immerse the bearing sample in a stearic acid ethanol solution with a mass percentage of 3% for 10 hours, then take it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com