Solid scale inhibitor and preparation method thereof

A scale inhibitor, solid technology, applied in chemical instruments and methods, earthwork drilling, cleaning appliances, etc., can solve the problems of short drug effect cycle, large manpower, financial resources, increase production cost, etc., and reduce the number of fillings. , High anti-scaling rate and anti-scaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

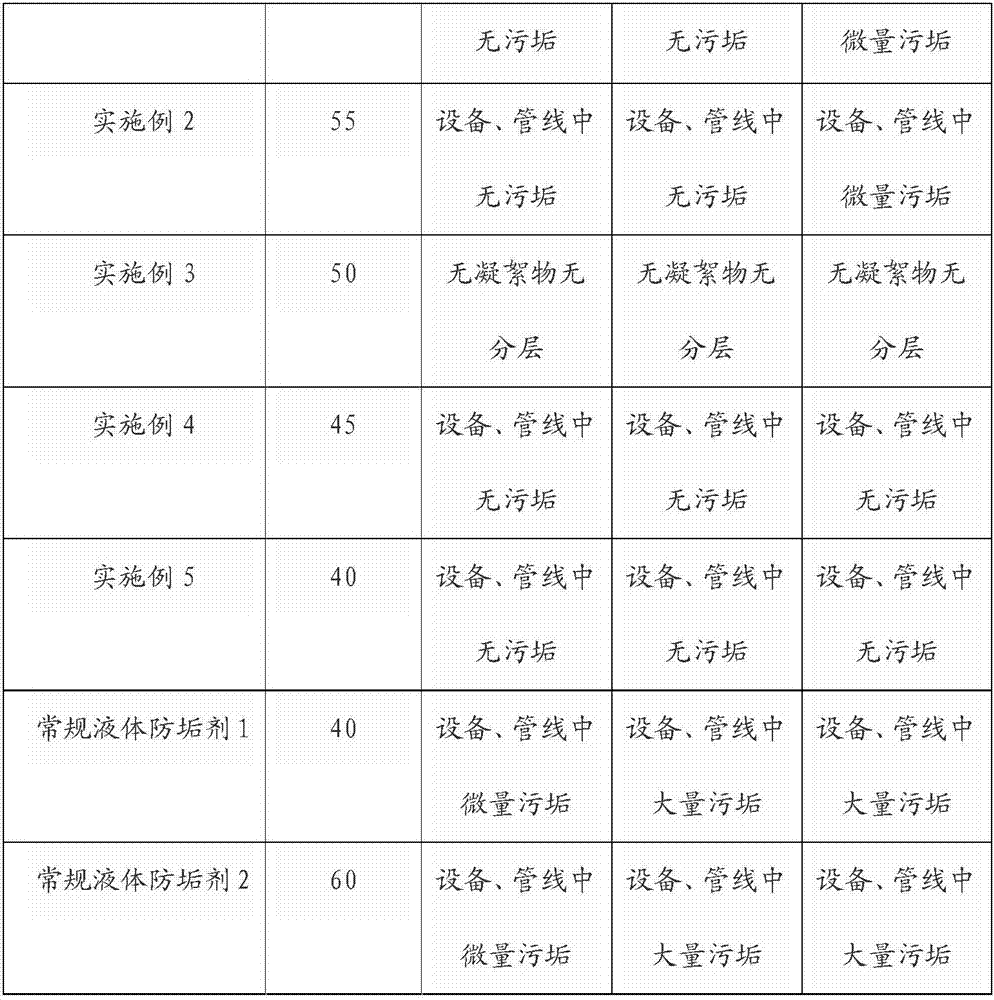

Examples

Embodiment 1

[0017] Solid antiscaling agent, the composition is as follows:

[0018] Including anti-scaling main agent and cementing agent, the ratio of anti-scaling main agent and cementing agent is 1:1; wherein the anti-scaling main agent includes by weight: 40 parts of hydroxyethylene diphosphonic acid, 40 parts of polyol phosphate, 3 parts of sodium hexametaphosphate, 7 parts of sodium molybdate; the cementing agent includes by weight: 5 parts of alum, 25 parts of epoxy resin, 8 parts of polyamide, 13 parts of epoxy thinner, and 18 parts of silane coupling agent.

[0019] Wherein, the preparation of the silane coupling agent comprises the following process: first, metal terephthalate and calcium oxide are added together at a speed of stirring tank (2000 revolutions / min) and stirred for 5 minutes, then chlorinated paraffin is added to mix, and the mixture is mixed at 2000 revolutions. Stir at a speed of 10 min at a speed of 2000 rpm for 10 min, then add bis(triethoxysilylpropyl) disulfi...

Embodiment 2

[0025] Solid antiscaling agent, the composition is as follows:

[0026] Including anti-scaling main agent and cementing agent, the ratio of anti-scaling main agent and cementing agent is 1:1; wherein the anti-scaling main agent includes by weight: 35 parts of hydroxyethylene diphosphonic acid, 30 parts of polyol phosphate, 2 parts of sodium hexametaphosphate, 6 parts of sodium molybdate; cementing agent includes by weight: 5 parts of alum, 20-30 parts of epoxy resin, 7 parts of polyamide, 13 parts of epoxy diluent, 19 parts of silane coupling agent .

[0027] Wherein, the making of silane coupling agent comprises the following process: first, metal terephthalate and calcium oxide are added together at a speed of stirring tank (2000 rpm / min) and stirred for 6 minutes, then chlorinated paraffin is added to mix, and then mixed with 2000 rpm Stir at a speed of 10 min at a speed of 2000 rpm for 10 min, then add bis(triethoxysilylpropyl) disulfide (Si75) at a constant speed, contin...

Embodiment 3

[0033] Solid antiscaling agent, the composition is as follows:

[0034] Including anti-scaling main agent and cementing agent, the ratio of anti-scaling main agent and cementing agent is 1:1; wherein the anti-scaling main agent includes by weight: 44 parts of hydroxyethylene diphosphonic acid, 37 parts of polyol phosphate, 3.5 parts of sodium hexametaphosphate, 7 parts of sodium molybdate; the cementing agent includes by weight: 3.5 parts of alum, 23 parts of epoxy resin, 8 parts of polyamide, 14 parts of epoxy diluent, and 19 parts of silane coupling agent.

[0035] Wherein, the preparation of the silane coupling agent comprises the following process: first, metal terephthalate and calcium oxide are added together at a speed of stirring tank (2000 revolutions / min) and stirred for 5 minutes, then chlorinated paraffin is added to mix, and the mixture is mixed at 2000 revolutions. Stir at a speed of 15 min at a speed of 2000 rpm for 15 min, then add bis(triethoxysilylpropyl) dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com