Wet type metallization treatment monitoring and controlling system for policapram or polyethylene terephthalate base material

A polyethylene terephthalate, metallization treatment technology, applied in metal material coating process, liquid chemical plating, coating and other directions, can solve the problem of expensive metal targets, difficult pattern etching, continuous vacuum Problems such as expensive investment in the evaporation processing chamber system, to achieve the effect of ensuring the growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]The implementation of the present invention will be described in more detail below with reference to the drawings and reference numerals, so that those skilled in the art can implement it after studying this specification.

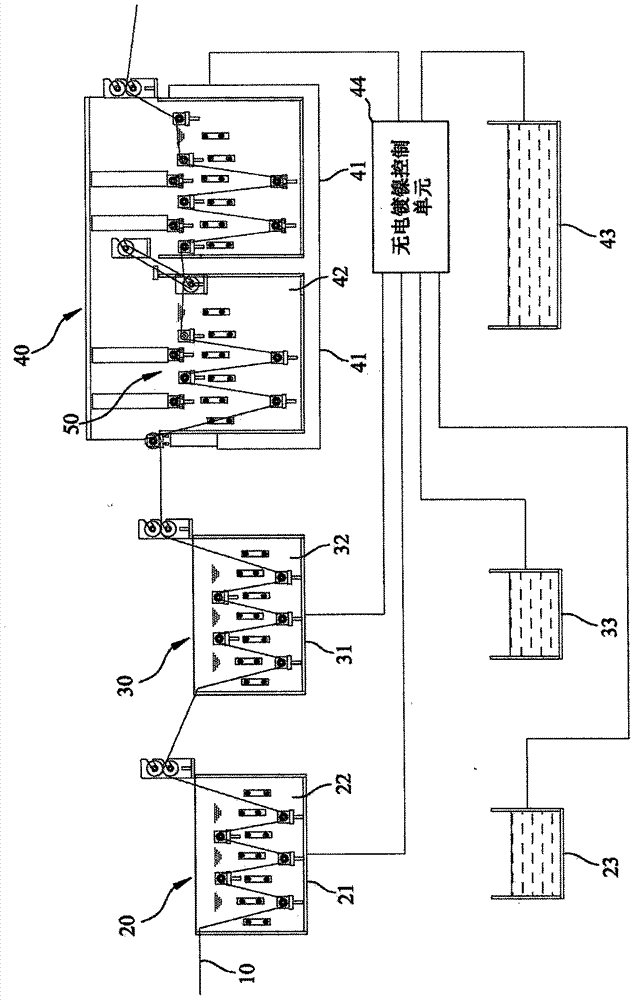

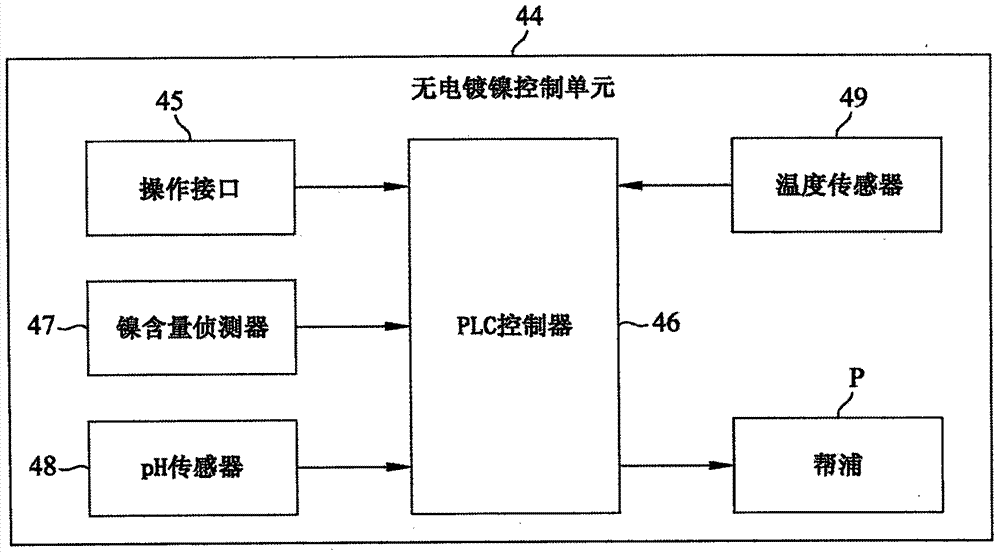

[0044] refer to figure 1 , a schematic diagram of a monitoring and control system for wet metallization of polyacetamide (Polyimide, PI) or polyethylene terephthalate (Polyethylene terephthalate, PET) substrates of the present invention. Such as figure 1 Shown, the polyacetamide of the present invention or the wet type metallization treatment monitoring control system of polyethylene terephthalate base material can be in the polyacetamide of strip film or polyethylene terephthalate base material 10 for wet metallization treatment, especially, the wet metallization treatment monitoring and control system of the present invention mainly includes silane coupling unit 20, catalytic treatment unit 30 and electroless nickel plating treatment unit 40, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com