Method for detecting blowby of oven wall of carbonization chamber of coke oven

A carbonization chamber and furnace wall technology, which can solve problems such as shortening the service life of coke ovens, temperature rise, and furnace temperature fluctuations by detecting the appearance of fluid at leak points, measuring devices, and measuring color/spectral characteristics. Achieve the effects of reducing the fluctuation range of sulfur dioxide content, preventing further expansion, and stabilizing the content of particulate matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

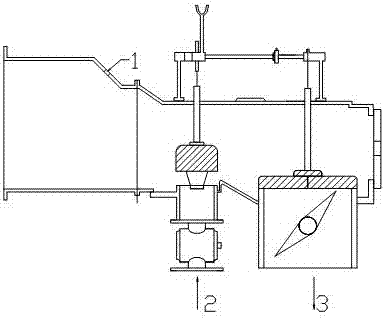

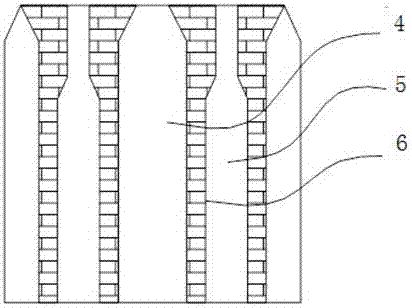

[0027] The principle of the present invention is: when the furnace wall of the carbonization chamber is not tightly sealed, the SO2 in the exhaust gas discharged from the combustion chamber is mainly produced by the combustion of heating coal gas and raw coal gas leaked from the carbonization chamber to combustion. During the coke oven exchange process, the gas flow for combustion decreases, the pressure in the carbonization chamber decreases and the air is relatively sufficient. At this time, the SO2 in the exhaust gas is mainly caused by the burning of raw coal gas leaked from the carbonization chamber to the combustion chamber. Through the comparison of the exchange process The amount of SO2 contained in the exhaust gas during the neutralization and non-exchange process can determine the degree of blowby in the coke oven carbonization chamber. Then carry out targeted treatment according to the leakage degree of the furnace wall of the carbonization chamber to prevent further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com