Methods of Improving the Specific Capacitance of Electric Double Layer Capacitors

An electric double layer capacitor and specific capacitance technology, applied in the field of capacitors, can solve the problems of low ionic conductivity, large equivalent internal resistance, low liquid absorption rate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

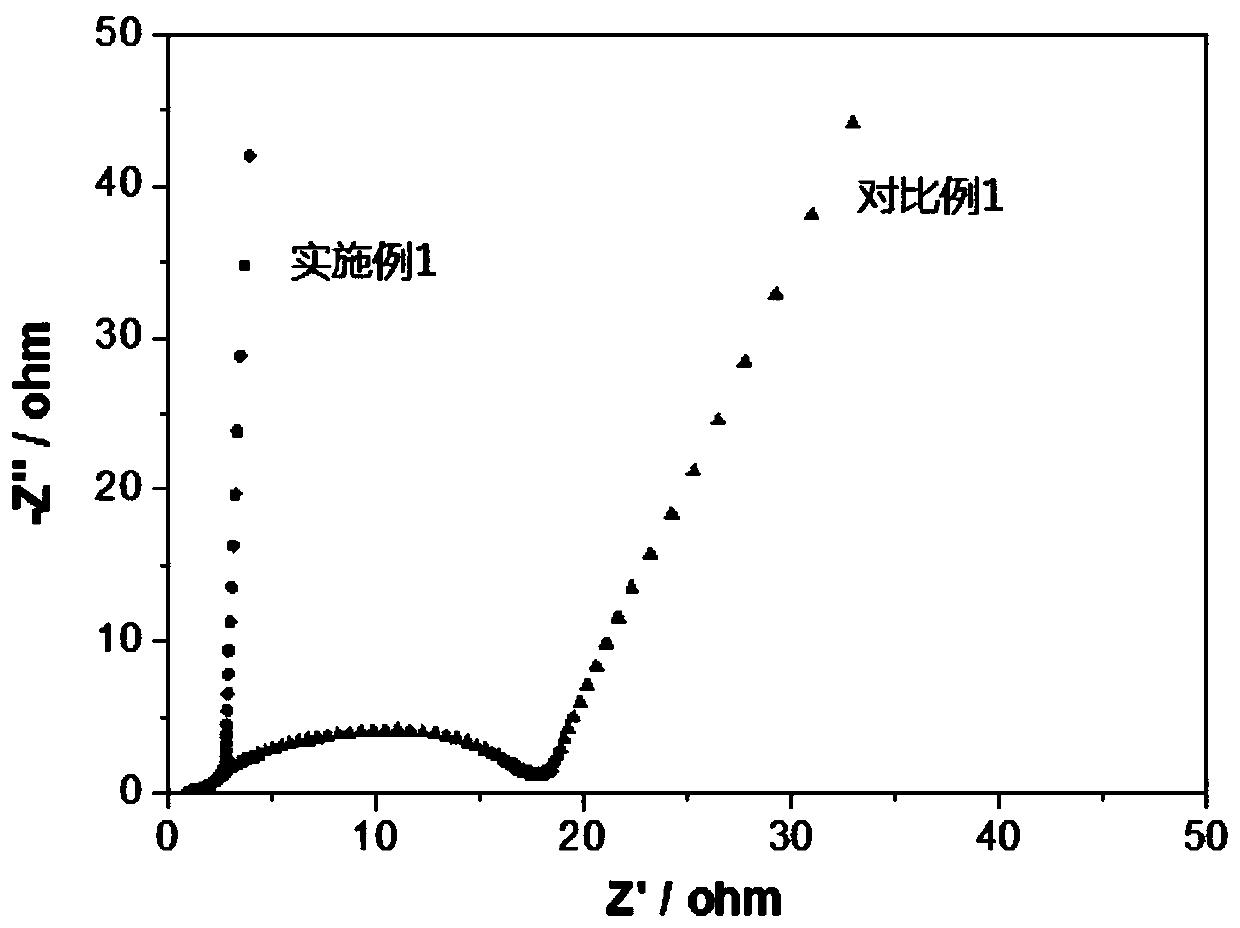

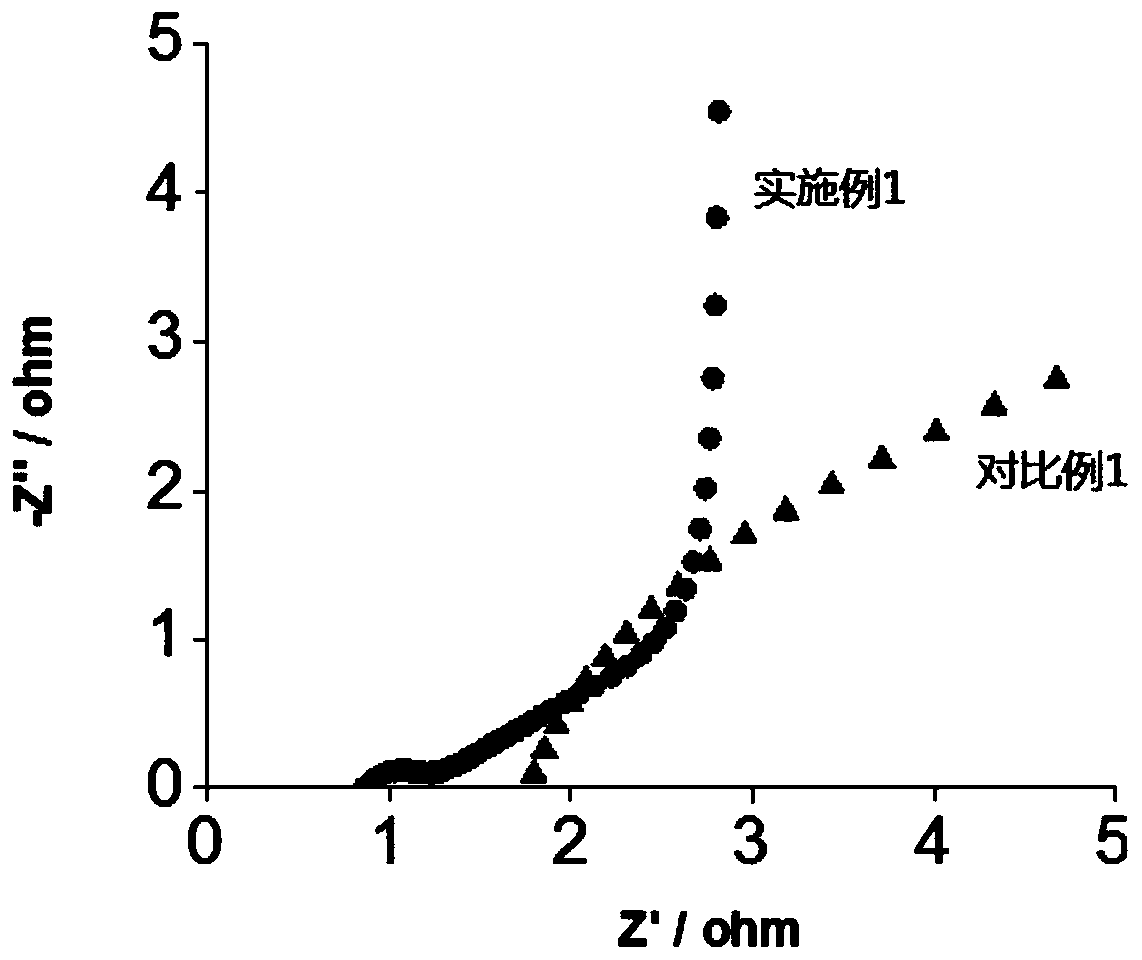

Embodiment 1

[0047] Step 1: Peel, clean and cut the eggshell membrane from the eggshell to a size of 1.2cm×1.2cm;

[0048] Step 2. Configure the egg white-based gel electrolyte. The egg white-based gel electrolyte is composed of egg white, water and sodium chloride. The volume ratio of egg white to water is 8:2, and the concentration of sodium chloride is 1mol / L ;

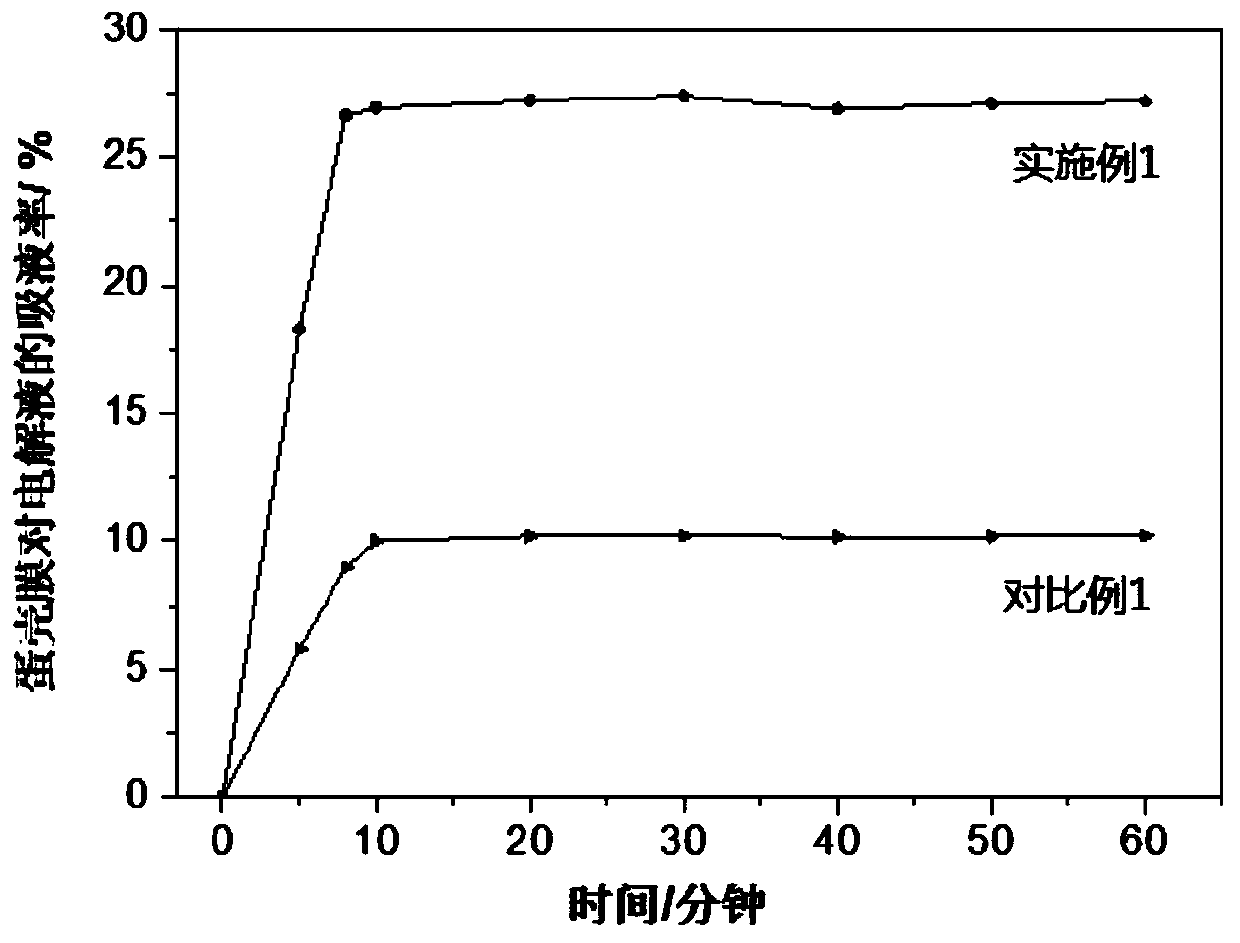

[0049] Step 3. Place the cut eggshell membrane in the egg white-based gel electrolyte for 10 minutes to obtain the eggshell membrane that absorbs the egg white-based gel electrolyte, wipe the excess electrolyte on the surface of the eggshell membrane to obtain the egg white-based gel electrolyte , The absorption rate of the eggshell membrane to the electrolyte is 27%;

[0050] Step 4: Assemble the egg white-based gel electrolyte and rice husk-based activated carbon electrode (1cm×1cm) in a sandwich structure, using tin foil as the current collector, and using transparent tape as a simple packaging material to avoid evaporation of the...

Embodiment 2

[0055] Step 1: Peel, clean and cut the eggshell membrane from the eggshell to a size of 1.2cm×1.2cm;

[0056] Step 2. Configure the egg white-based gel electrolyte. The egg white-based gel electrolyte is a combination of egg white, water and sodium chloride. The volume ratio of egg white to water is 10:0, and the concentration of sodium chloride is 1mol / L. ;

[0057] Step 3. Place the cut eggshell membrane in the egg white-based gel electrolyte for 10 minutes to obtain the eggshell membrane that absorbs the egg white-based gel electrolyte, wipe the excess electrolyte on the surface of the eggshell membrane to obtain the egg white-based gel electrolyte , The absorption rate of the eggshell membrane to the electrolyte is 19%;

[0058] Step 4: Assemble the egg white-based gel electrolyte and rice husk-based activated carbon electrode (1cm×1cm) in a sandwich structure, using tin foil as the current collector, and using transparent tape as a simple packaging material to avoid evaporation...

Embodiment 3

[0061] Step 1: Peel, clean and cut the eggshell membrane from the eggshell to a size of 1.2cm×1.2cm;

[0062] Step 2. Configure egg white-based gel electrolyte. The egg white-based gel electrolyte is a combination of egg white, water and sodium chloride. The volume ratio of egg white to water is 1:9, and the concentration of sodium chloride is 1mol / L. ;

[0063] Step 3. Place the cut eggshell membrane in the egg white-based gel electrolyte for 10 minutes to obtain the eggshell membrane that absorbs the egg white-based gel electrolyte, wipe the excess electrolyte on the surface of the eggshell membrane to obtain the egg white-based gel electrolyte , The absorption rate of the eggshell membrane to the electrolyte is 11%;

[0064] Step 4: Assemble the electrolyte membrane egg white-based gel electrolyte and rice husk-based activated carbon electrode (1cm×1cm) in a sandwich structure, using tin foil as the current collector, in order to avoid the evaporation of electrolyte water, use tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com