Platinum coated gold nanocrystal material and preparation method and application thereof

A gold nano-coating technology, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of difficult coating thickness, difficulty in obtaining core nanoparticles with uniform size, etc., and achieves the goal of preparing The method is simple and fast, the catalytic performance is good, and the treatment process is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

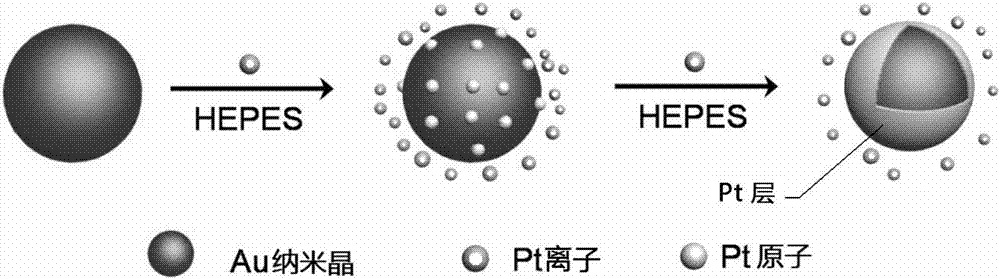

[0035] The invention provides a method for preparing a platinum-coated gold nanocrystal material, comprising the following steps:

[0036] a) Gold nanocrystals, piperazine derivatives and platinum source compounds are mixed and reacted in a solvent to obtain a platinum-coated gold nanocrystal material.

[0037] In the present invention, the platinum-coated gold nanocrystal material can be obtained by mixing and reacting gold nanocrystals, piperazine derivatives and platinum source compounds in a solvent. Wherein, the gold nanocrystals include but are not limited to spherical gold nanocrystals and / or flower-shaped gold nanocrystals; the particle size of the gold nanocrystals is preferably 1 to 100 nm, more preferably 10 to 50 nm, and more preferably 13 nm. ~30nm, most preferably 15nm. The present invention has no special limitation on the source of the gold nanocrystals, wherein the spherical gold nanocrystals can be prepared according to the following method:

[0038] The go...

Embodiment 1

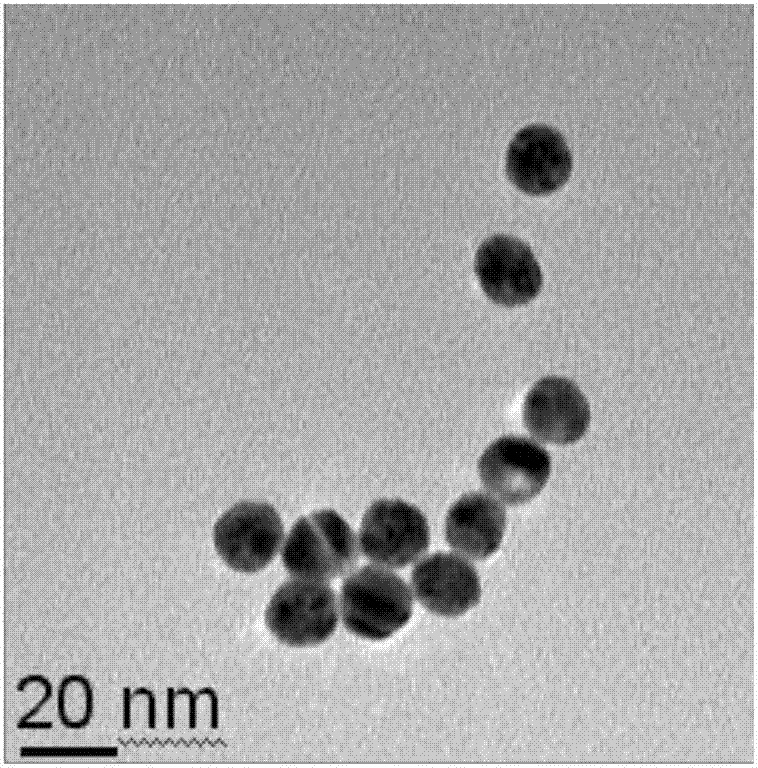

[0055] 1) Synthesis of spherical gold nanocrystals

[0056] Add 100mL double-distilled water into a 250ml volumetric flask, heat to boiling; add 2mL of 1% HAuCl 4 The solution was added to the volumetric flask to obtain HAuCl 4 Aqueous solution, heated to boiling; 4mL of 2% sodium citrate solution by mass percentage was added to the above-mentioned volumetric flask, and continued heating under stirring, the color of the solution changed from light yellow to blue-black, and finally wine red, continued stirring and heating for 1 Hour. Cool at room temperature, centrifuge at 9600rpm for 15min, discard the supernatant to obtain spherical gold nanocrystals with a particle size of 15nm; redisperse the spherical gold nanocrystals in water and make the concentration of spherical gold nanocrystals It is 4nmol / L and is ready for use.

[0057] 2) Synthesis of platinum-coated spherical gold nanocrystals

[0058] according to figure 1 The process shown in the preparation of platinum-c...

Embodiment 2

[0066] 1) Synthesis of spherical gold nanocrystals

[0067] Add 100mL double-distilled water into a 250mL volumetric flask, heat to boiling; add 2mL of 1% HAuCl 4 The solution was added to the volumetric flask to obtain HAuCl 4 Aqueous solution, heated to boiling; 4mL of 2% sodium citrate solution by mass percentage was added to the above-mentioned volumetric flask, and continued heating under stirring, the color of the solution changed from light yellow to blue-black, and finally wine red, continued stirring and heating for 1 Hour. Cool at room temperature, centrifuge at 9600rpm for 15min, discard the supernatant to obtain spherical gold nanocrystals with a particle size of 15nm; redisperse the spherical gold nanocrystals in water and make the concentration of spherical gold nanocrystals It is 4nmol / L and is ready for use.

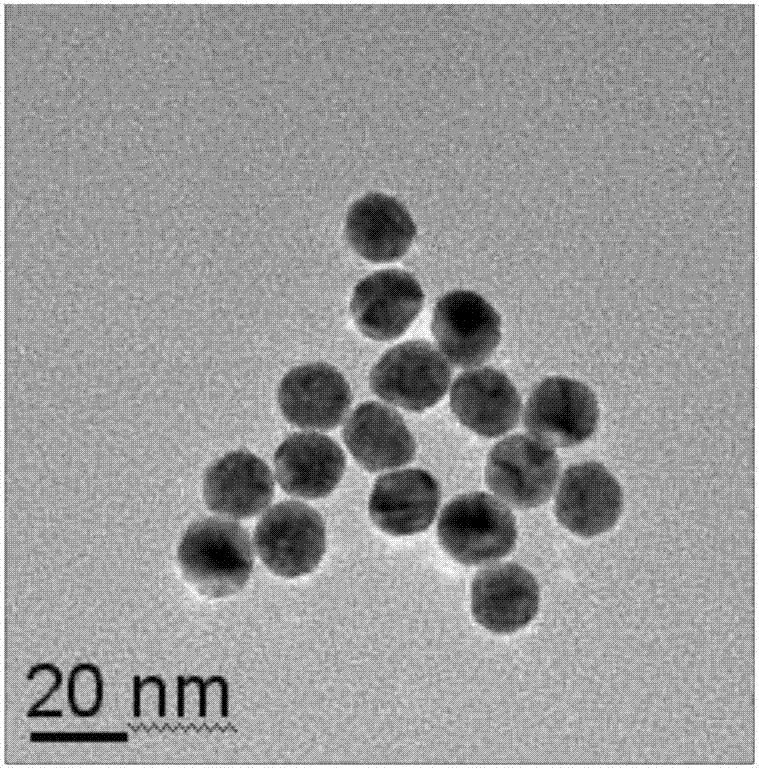

[0068] 2) Synthesis of platinum-coated spherical gold nanocrystals

[0069] 5ml of the spherical gold nanocrystal solution with a concentration of 4n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com