Mixed resin, retardation film and a liquid-crystal display device comprising the same

A technology of liquid crystal display device and retardation film, which is applied in the direction of instruments, optics, optical components, etc., can solve the problems of non-perpendicular optical axes and light leakage, and achieve low photoelastic coefficient, excellent heat resistance, and excellent retardation realization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

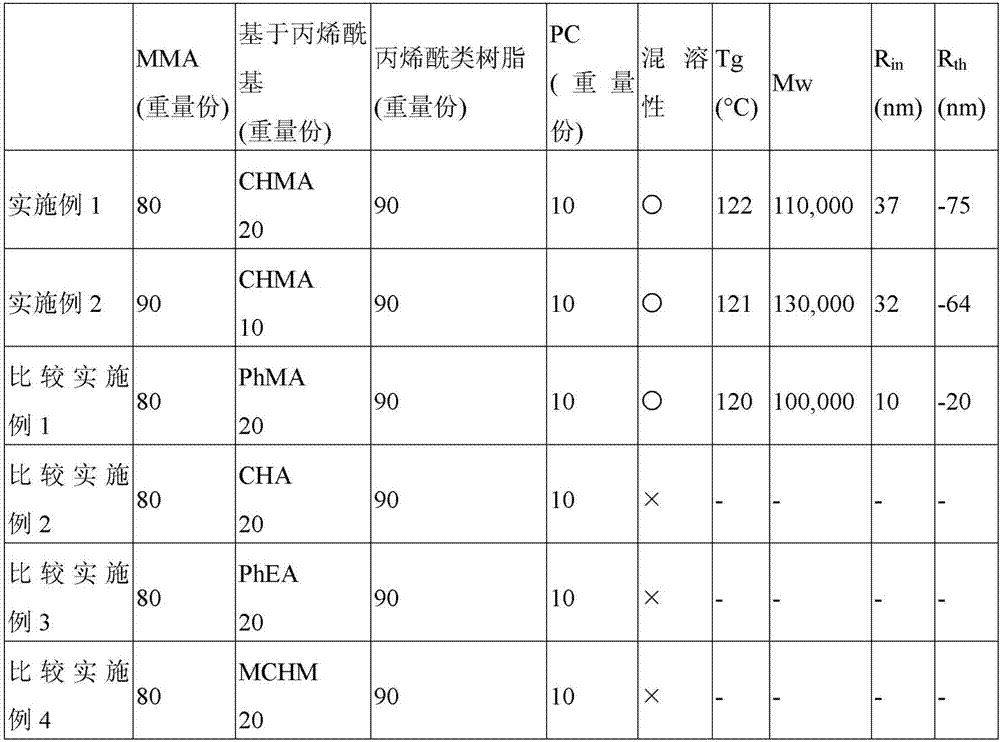

[0071] A resin was prepared by using 90 parts by weight of a copolymer of methyl methacrylate (80 parts by weight) and cyclohexyl methacrylate (20 parts by weight) and 10 parts by weight of polycarbonate. The glass transition temperature and molecular weight of the prepared resin were measured, and as a result, a resin having a glass transition temperature of 122° C. and a molecular weight of 110,000 was obtained. A film was produced from the resin using a solution casting method, and the film was stretched at a glass transition temperature, and then the retardation value of the film was measured. As a result, the in-plane retardation value / thickness retardation value were 37 nm / -75 nm.

Embodiment 2

[0073] A resin was prepared by using 90 parts by weight of a copolymer of methyl methacrylate (90 parts by weight) and cyclohexyl methacrylate (10 parts by weight) and 10 parts by weight of polycarbonate. The glass transition temperature and molecular weight of the prepared resin were measured, and as a result, a resin having a glass transition temperature of 121° C. and a molecular weight of 130,000 was obtained. A film was produced from the resin using a solution casting method, and the film was stretched at a glass transition temperature, and then the retardation value of the film was measured. As a result, the in-plane retardation value / thickness retardation value were 32 nm / -64 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com