New high-strength quick-hardened Al-Mg-Si-Cu alloy used for automobile body and preparation method of alloy

A rapid hardening, automobile body technology, applied in the field of aluminum alloy materials, to achieve the effect of high corrosion resistance, high aging strength, and low rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An excess Mg high Cu alloy by mass consists of the following components: Mg: 1.17wt.%; Si: 0.57wt.%, Cu: 0.5wt.%, Mn: 0.06wt.%, Fe: 0.17wt.% , The rest is Al.

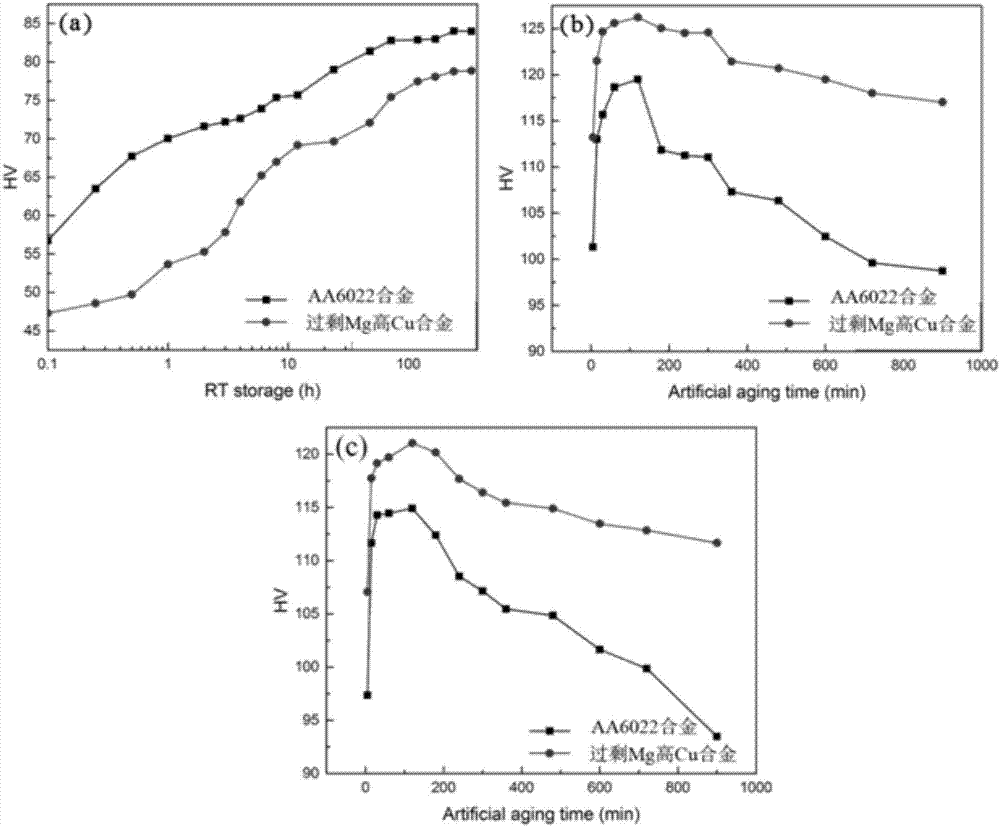

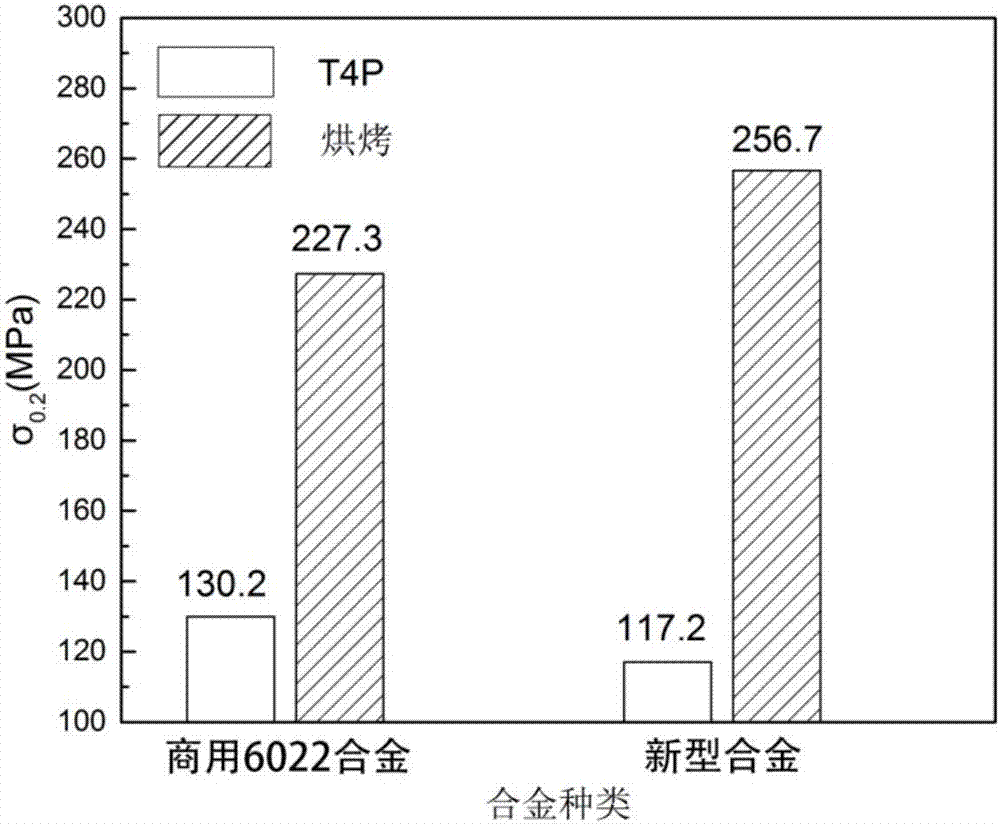

[0028] The alloy uses 99.98% industrial pure aluminum, pure Mg, Al-Si master alloy and Al-Cu master alloy as raw materials. Under the condition of a melting temperature of 660°C, firstly add industrial pure aluminum and add Al-Si after it is completely melted Master alloy; after completely melted, add Al-Cu master alloy, after completely melted, add pure Mg to ensure uniform mixing of the melt, then pour the melt into water-cooled steel molds with length, width, and height of 300mm, 200mm, and 60mm respectively. , And then cut the ingot, and sequentially carry out homogenization treatment, solution water quenching, and aging treatment. The cold-rolled sheet is first subjected to solution treatment at 560°C for 30 minutes, and then water quenched to room temperature, followed by 3 types of aging treatments: 1. Afte...

Embodiment 2

[0047] An excess Mg high Cu alloy by mass consists of the following components: Mg: 1.17wt.%; Si: 0.57wt.%, Cu: 0.5wt.%, Mn: 0.06wt.%, 0.17wt.%, and the rest Is Al.

Embodiment 3

[0049] An excess Mg high Cu alloy by mass consists of the following components: Mg: 1wt.%; Si: 0.3wt.%, Cu: 1.5wt.%, Mn: 0.20wt.%, Fe: 0.1wt.%, The rest is Al.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com