Energy bar containing zein and preparation technology thereof

A technology of zein and energy bars, which is applied in the food field, can solve the problems that the improvement effect of xanthan gum cannot be reflected, the hardness correlation of energy bars is not high, and the quality of energy bars is affected, so as to inhibit moisture migration, improve hardening, Slow down the effect of hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

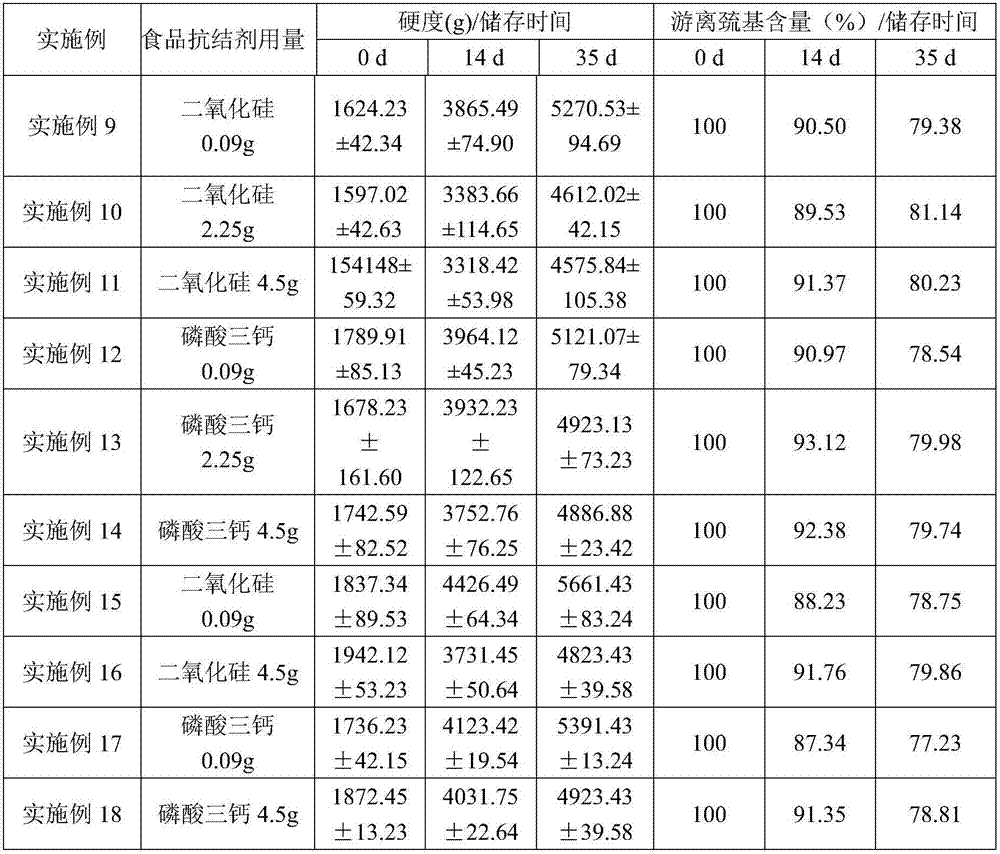

Examples

Embodiment 1

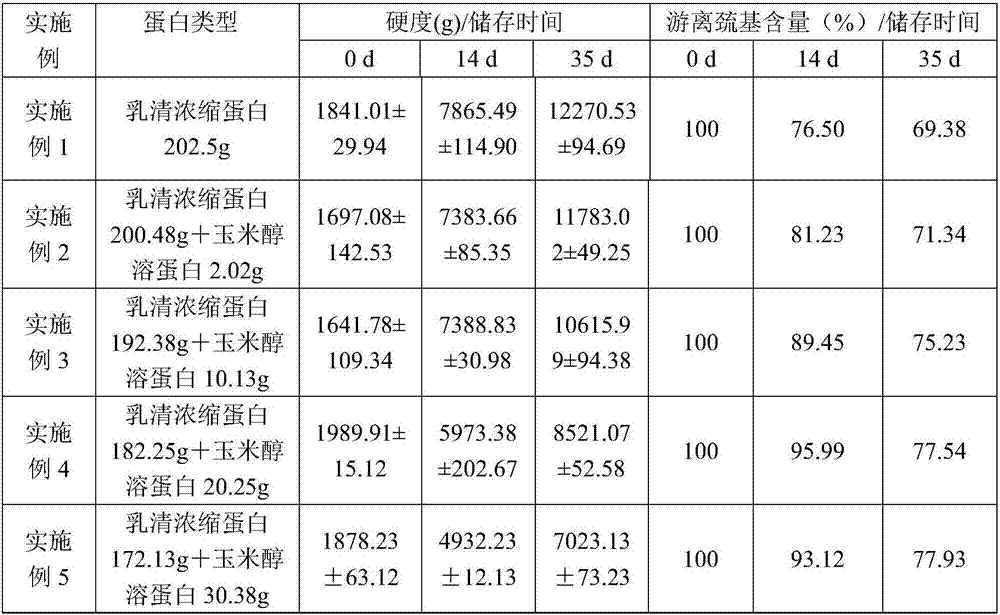

[0019] Embodiment 1 Preparation of control group energy bar

[0020] 1) The preparation method of the energy bar of the control group: weigh 216g of maltose syrup, 18g of coconut oil, 9g of glycerin, and 4.5g of soybean lecithin in a stainless steel bowl , heated and stirred on a water bath at 60°C to fully mix the liquid system evenly, then fully mix the liquid mixture with 202.5g protein powder (45 parts), then shape, equilibrate at room temperature for 2 hours, demould, and cut into strips ( About 30g / bar), finally packed in aluminum foil, and carried out accelerated storage test in a constant temperature incubator at 37°C. Measure the hardness and free sulfhydryl content on the 0th, 14th, and 35th day, and take out the samples respectively to test the corresponding parameters.

[0021] 2) Texture analysis method and free sulfhydryl content determination method are as follows:

[0022] Texture analysis method: take the samples out of the constant temperature incubator, tak...

Embodiment 2-6

[0025] A technical solution utilizing the effect of zein on the texture change of energy bars during storage is:

[0026]1) The preparation method of Example 2-6 refers to Example 1, the difference is that part of the whey protein powder is replaced by zein, and the mixed protein powder corresponding to Example 2-6 is respectively 200.48g of whey protein concentrate powder ( 44.55 parts) and zein 2.03g (0.45 parts) mixed protein powder, whey protein concentrate powder 192.38g (42.75 parts) and zein 10.13g (2.25 parts) mixed protein powder, whey protein concentrate Mixed protein powder of 182.25g (40.5 parts) of flour and 20.25g (4.5 parts) of zein protein, mixed protein of 172.13g (38,25 parts) of whey protein concentrate powder and 30.38g (6.75 parts) of zein protein powder, whey protein concentrate powder 162g (36 parts) and zein 40.5g (9 parts) mixed protein powder. The prepared energy bar was subjected to an accelerated storage test in a constant temperature incubator at ...

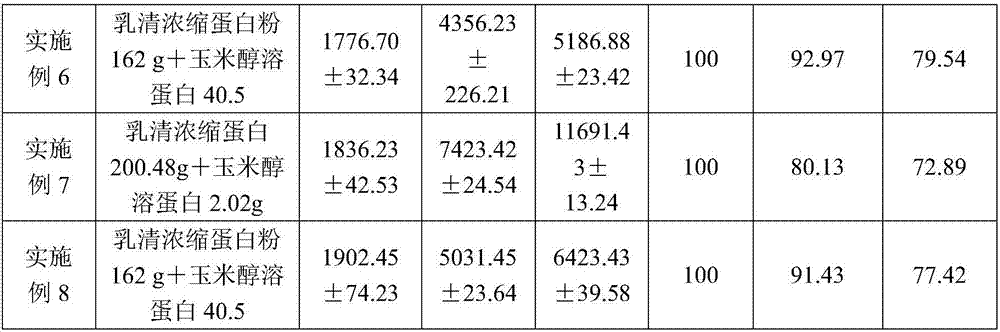

Embodiment 7

[0028] An energy bar containing zein, wherein the proportions by weight of maltose syrup, coconut oil, glycerin, soybean lecithin, and protein powder are respectively: 157.5g (35 parts) of maltose syrup, 13.5g (35 parts) of coconut oil ), glycerin 2.25 (0.50 parts), soybean lecithin 3.60g (0.8 parts), zein 2.03g (0.45 parts), whey protein concentrate powder 200.48g (44.55 parts).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com