Welding method of four-wing octagonal radio frequency quadrupole cavity

A radio frequency quadrupole field, welding method technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as high-voltage ignition, and achieve the effect of improving quality, reducing outflow, and excellent welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

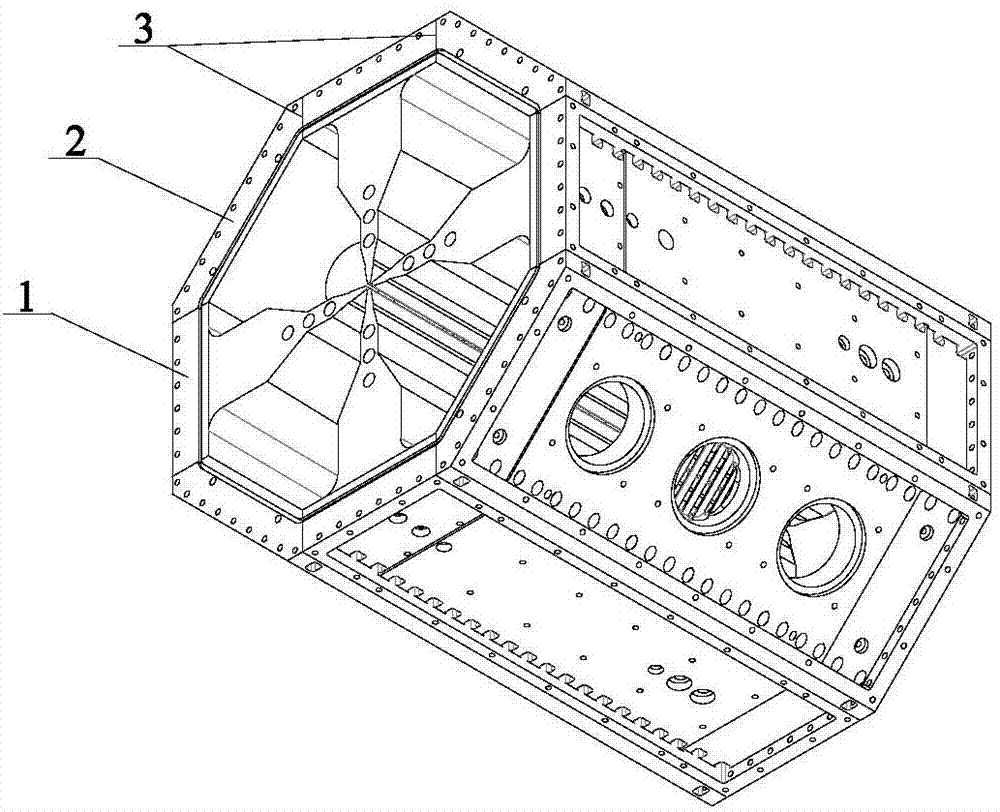

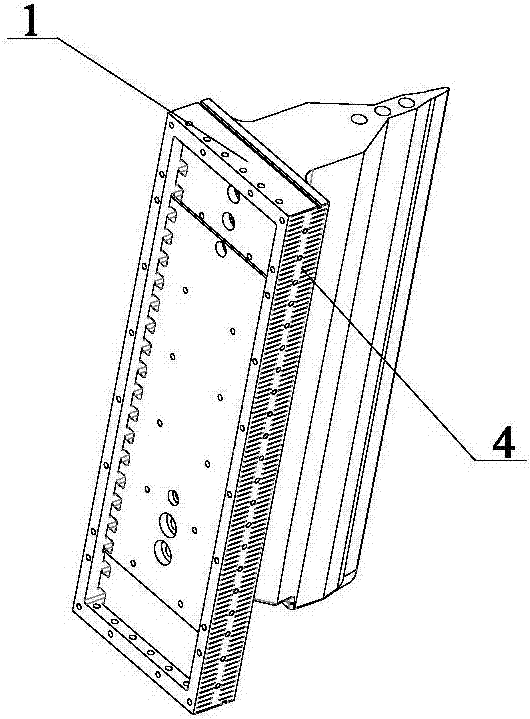

[0033] Such as figure 1 with figure 2 As shown, the side shape of the radio frequency quadrupole field accelerator cavity welded by the method of the present invention is an octagon, and the cavity includes an electrode 1 and a flank 2, wherein the electrode 1 includes two horizontal electrodes and two vertical electrodes, and the flank The number of 2 is four pieces; each electrode 1 is provided with an electrode solder tank 4 on both sides of each electrode 1, and the electrode solder tank 4 is loaded with an alloy filling material for welding, and the contact surface between the electrode 1 and the flank 2 is the welding surface 3. The size of the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com