A kind of micron single crystal lithium nickelate and its preparation method and application

A lithium nickelate, micron-scale technology is applied in the field of preparation of micron-scale single crystal lithium nickelate, can solve the problems of high activity of lithium source LiOH, high cost, large specific surface area of secondary particles, etc. The effect of reducing synthesis cost and excellent rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of the micron-sized single crystal lithium nickelate of the present embodiment comprises the following steps:

[0033] (1) NiCl 2 Dissolve in distilled water to form a solution with a metal ion concentration of 0.5mol / L;

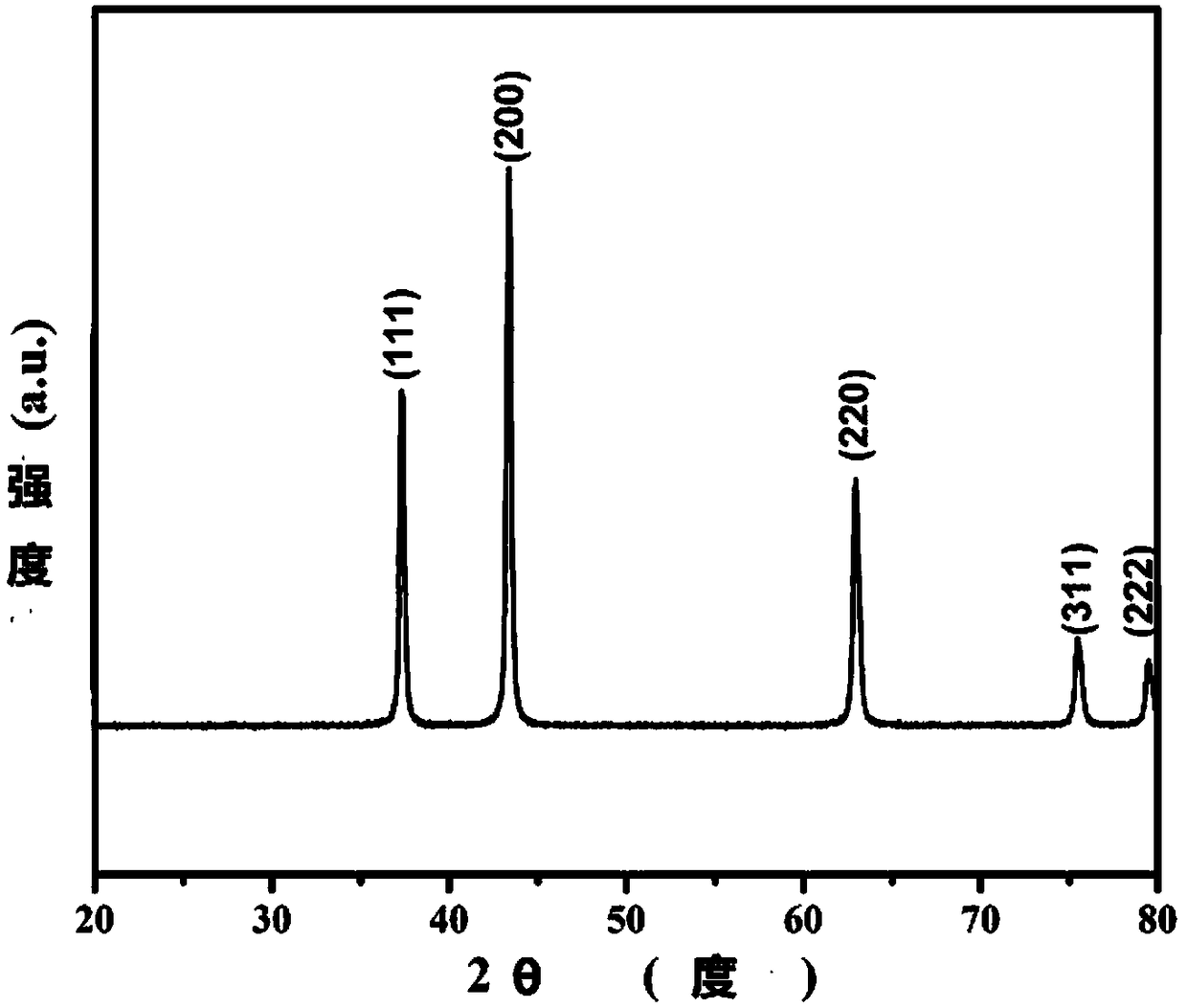

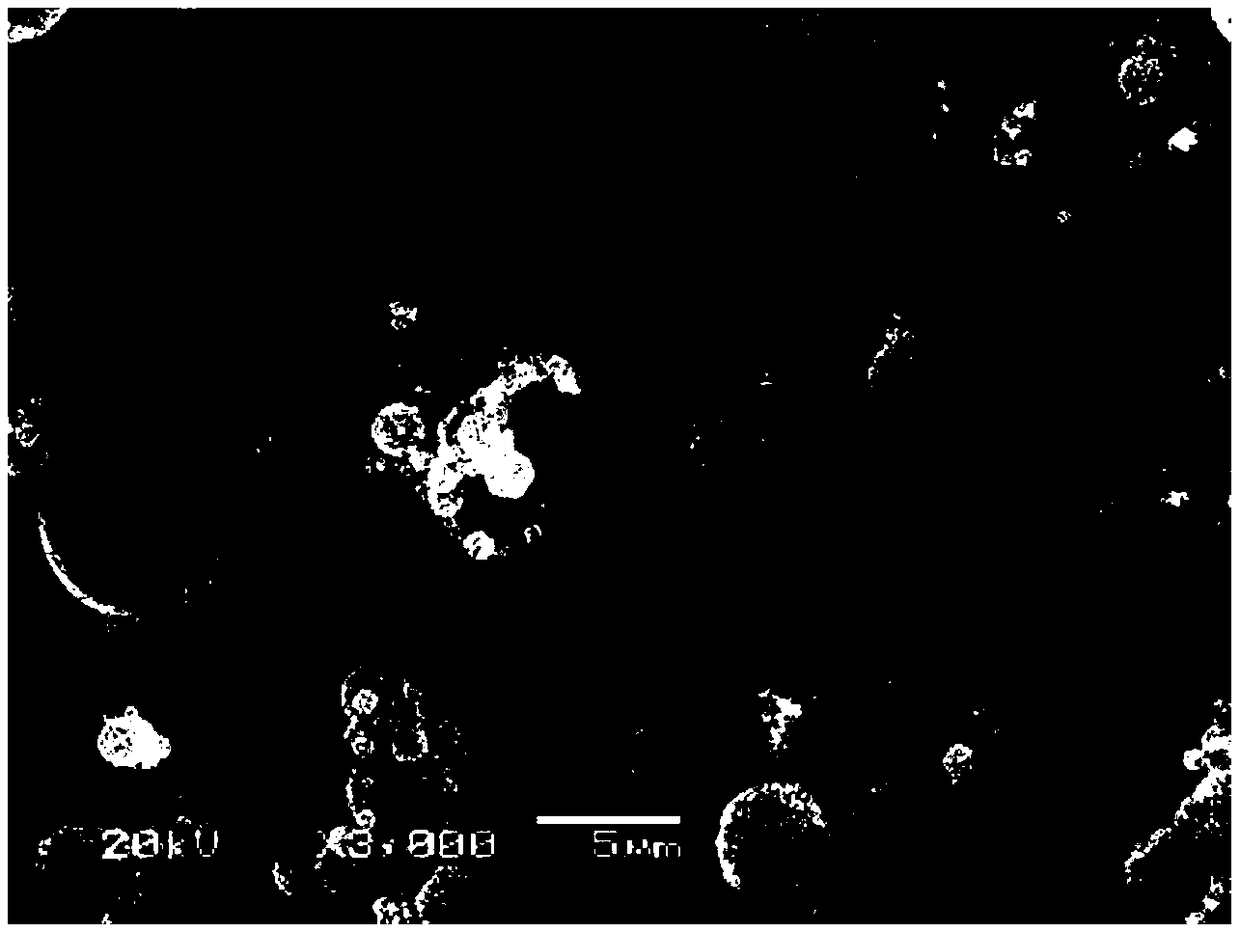

[0034] (2) NiCl obtained in step (1) 2 The solution was subjected to spray pyrolysis after ultrasonic atomization, the temperature of spray pyrolysis was 750°C, and the carrier gas was O 2 , the carrier gas flow rate is 6L / min, the residence time of the gas in the furnace is about 20s, and the powdery nickel oxide precursor is obtained, and the phase and morphology of the obtained powdery nickel oxide precursor are detected. figure 1 It is the XRD spectrum of the powdery nickel oxide precursor. figure 2 It is the SEM spectrum of the powder nickel oxide precursor, and it can be seen that the obtained product is a porous microsphere composed of many primary particles.

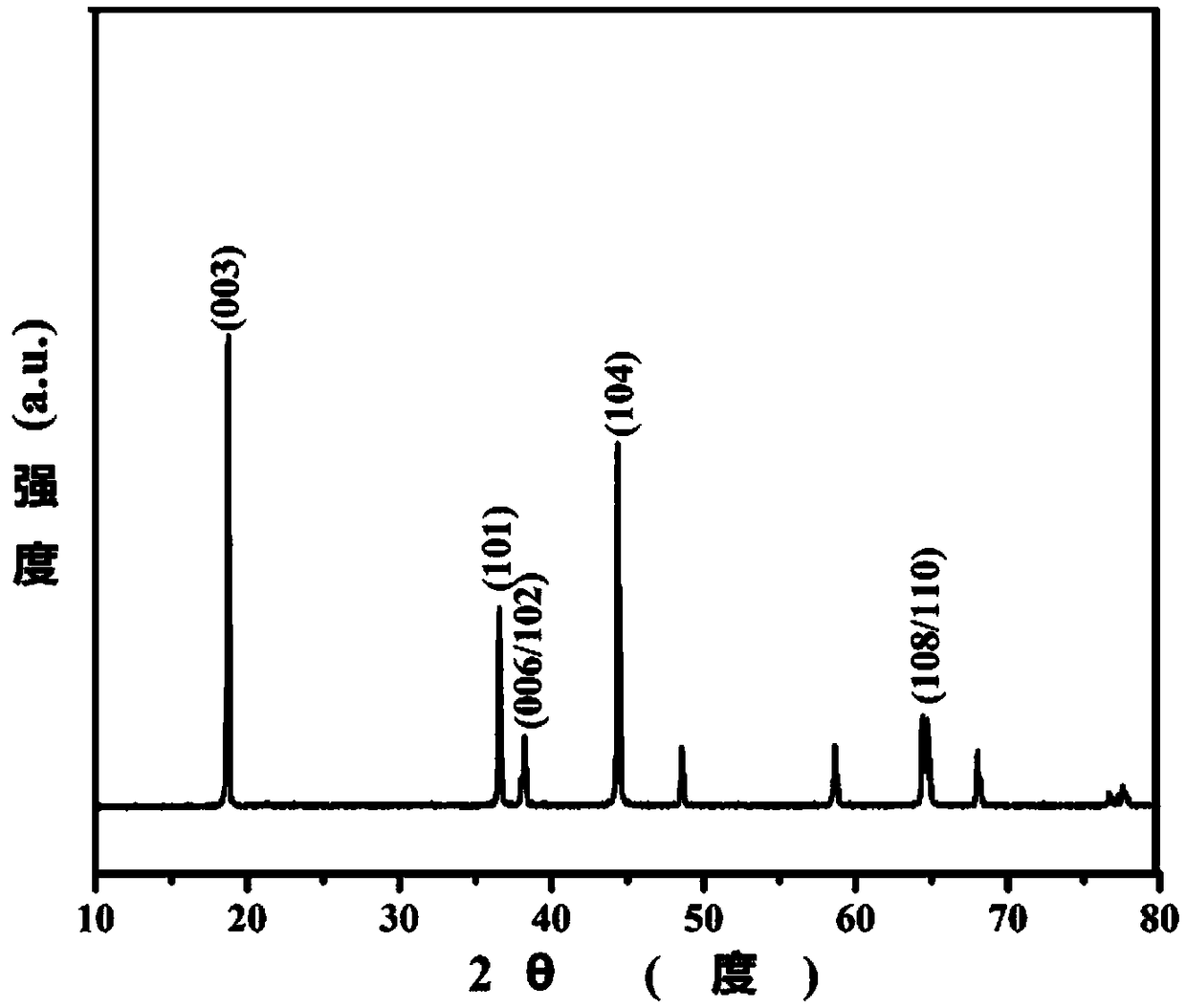

[0035] (3) After mixing and grinding the powdery nickel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com