A kind of microemulsion that delays the oxidation of feed oil and its preparation method

A microemulsion and feeding technology, which is applied in application, animal feed, and the use of additives to preserve fatty substances, etc., can solve the problems of limited use range, achieve thermodynamic and dynamic stability, low viscosity, and extend the shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

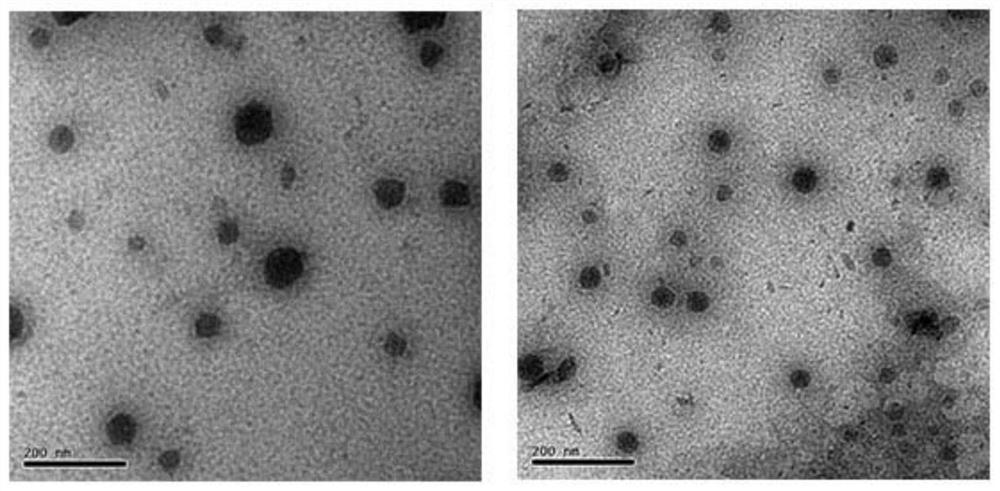

Embodiment 1

[0026] An embodiment of a microemulsion that delays the oxidation of fish oil for feeding according to the present invention, the microemulsion includes the following components in mass percentage: BHT 10%, 98% tea polyphenols 2%, paraffin oil 40%, lemon Acid 1%, Span80 21%, Tween80 7%, absolute ethanol 9%, water 10%.

[0027] The preparation method of microemulsion of the present invention is:

[0028] a) adding the synergist into water, stirring and dissolving, adding a co-emulsifier and a water-soluble antioxidant, stirring and dissolving at 40-50°C, and preparing the water phase of the microemulsion;

[0029] b) adding the fat-soluble antioxidant to the oil and heating and stirring to prepare the oil phase of the microemulsion;

[0030] c) adding an emulsifier to the water phase of the microemulsion prepared in step a), emulsifying at a speed of 300 to 600 r / min, adding the oil phase of the microemulsion prepared in step b) after emulsification, and stirring evenly at 40 ...

Embodiment 2

[0032] An embodiment of a microemulsion that delays the oxidation of fish oil for feeding according to the present invention, the microemulsion includes the following components in mass percentage: BHT 10%, 95% oligomeric proanthocyanidins 2%, paraffin oil 40%, lemon Acid 1%, Span80 21%, Tween80 7%, absolute ethanol 9%, water 10%.

[0033] The preparation method of microemulsion of the present invention is with embodiment 1.

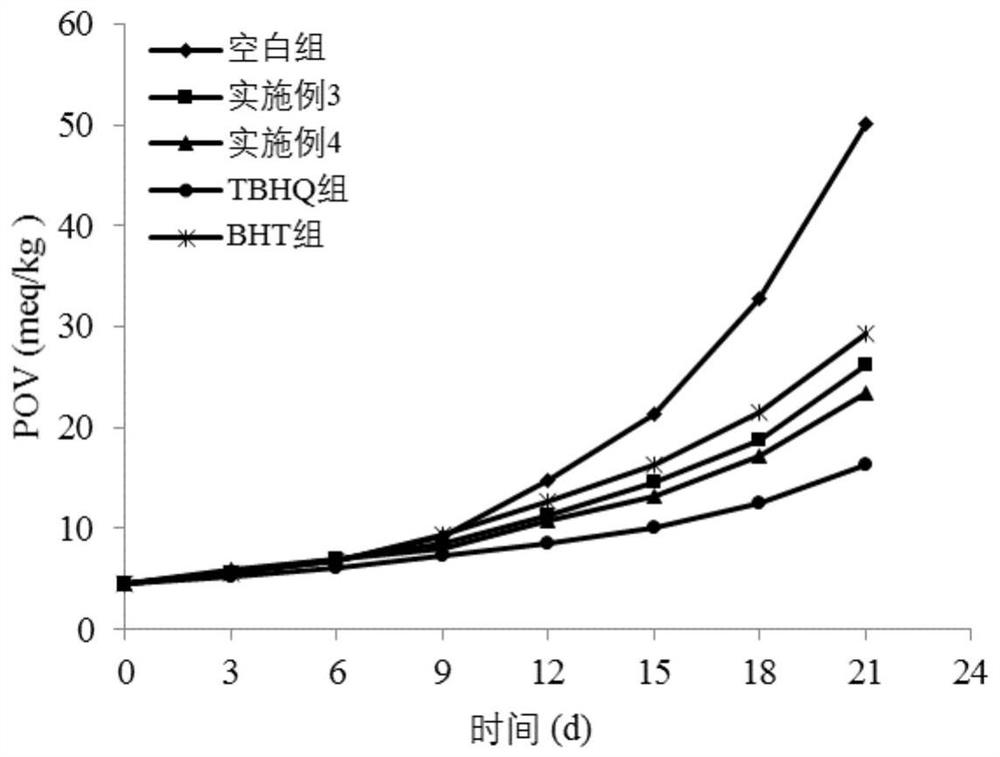

Embodiment 3

[0035] An embodiment of a microemulsion that delays the oxidation of fish oil for feeding according to the present invention, the microemulsion includes the following components in mass percentage: DLTP 10%, 98% tea polyphenols 2%, paraffin oil 40%, ascorbic acid 1%, Span80 22%, Tween80 7%, absolute ethanol 8%, water 10%.

[0036] The preparation method of microemulsion of the present invention is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com