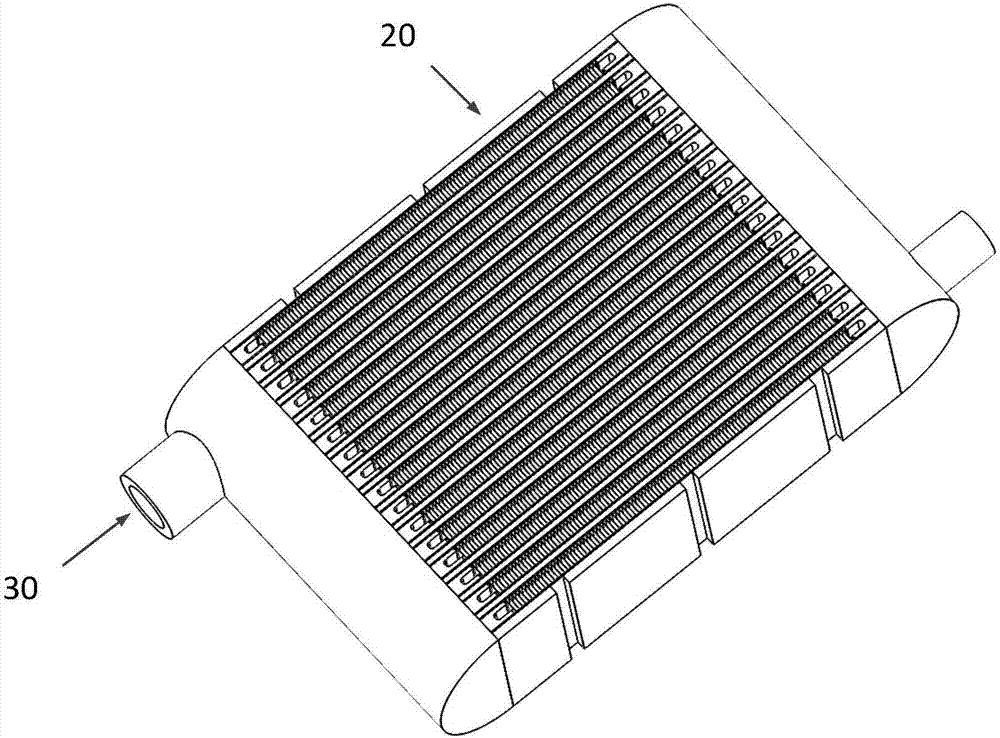

Cross-flow type aluminum plate fin heat exchanger provided with stress releasing seams, based on flexible seal strips and cover plates

A plate-fin heat exchanger and stress release technology, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the structural deformation of plate-fin heat exchangers, affecting industrial production efficiency and personnel safety , heat exchanger fatigue failure and other problems, to achieve the effect of reducing thermal stress, saving production consumables, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below with reference to the accompanying drawings and examples. The following examples are explanations of the present invention and are not limited to the following examples.

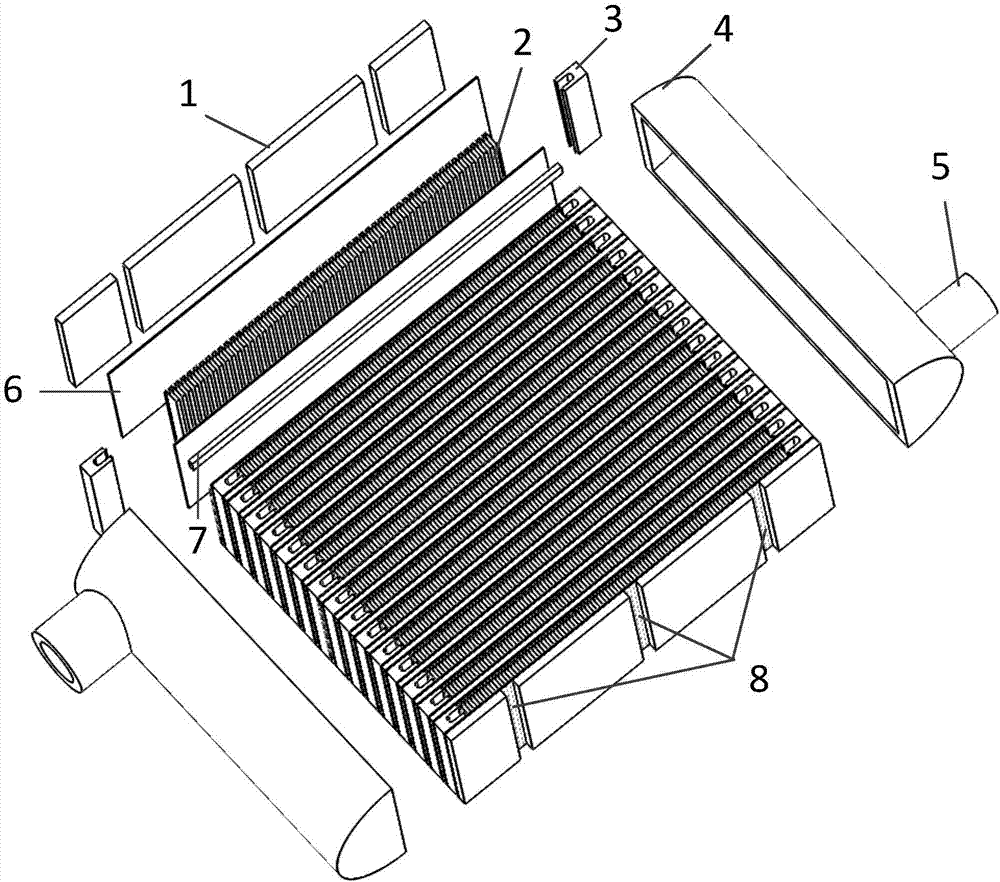

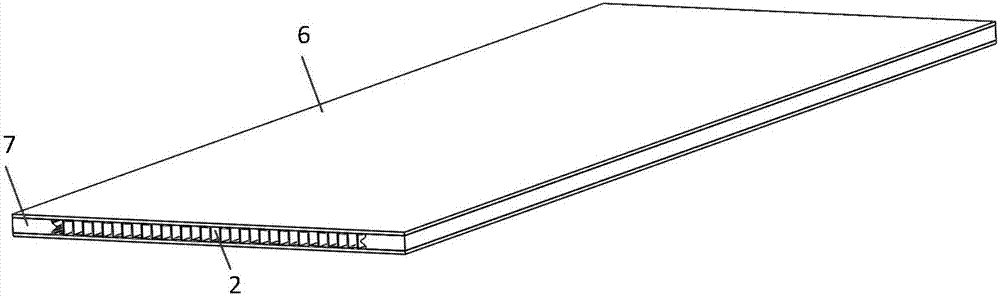

[0025] The new plate-fin heat exchanger of this embodiment is a cross-flow aluminum plate-fin heat exchanger based on flexible seals and cover plates with stress relief joints. It is mainly composed of a plate-fin heat exchanger core and a seal The core body of the heat exchanger is composed of several layers of hot channels and several layers of cold channels that are stacked and cross-flow arranged and brazed by the cover plate 1. The heat channel is two layers of separators 6 sandwiched by one layer. The fins 2 are sealed by a rectangular seal 7, and the cold aisle is a layer of fins 2 sandwiched between two layers of partitions 6 and sealed by a flexible seal 3; the outermost channels on both sides of the core are always cold aisles. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com