High sensitivity and high precision optical fiber shape sensing measuring method and system

A high-sensitivity, sensing measurement technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of limited sensing distance, increased fiber loss, and short boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

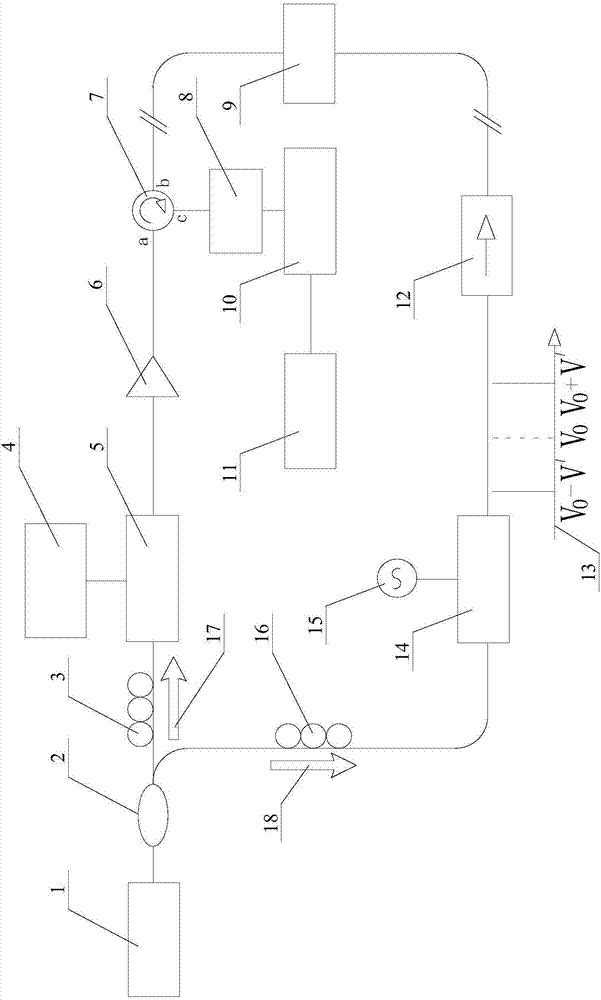

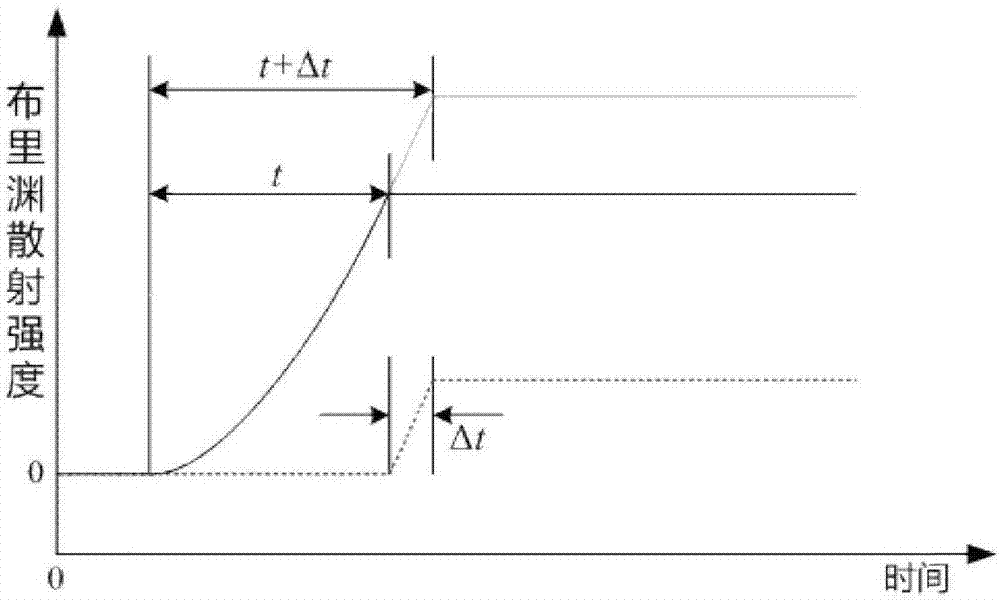

[0045] A measurement method of a high-sensitivity and high-precision optical fiber shape sensing system, such as image 3 and Figure 5 shown.

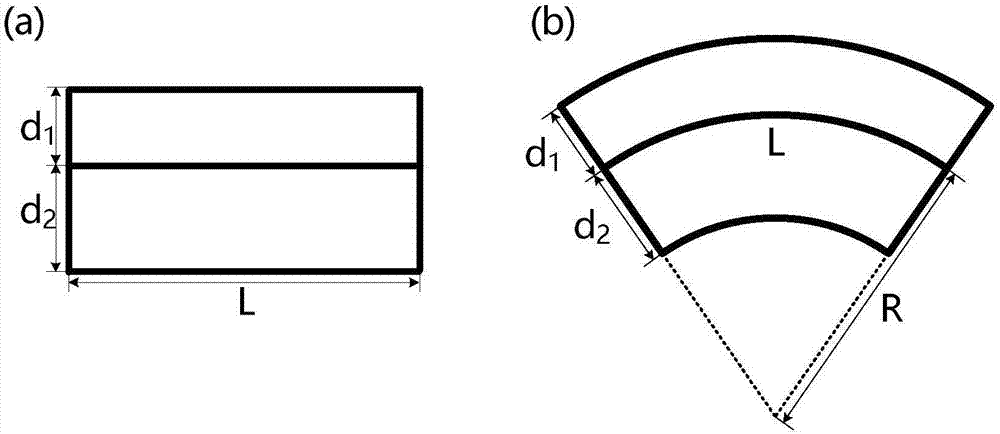

[0046] When an optical fiber is bent, one side of the fiber is stretched and the other side is compressed. It is assumed that the distance from the fiber core to the neutral axis (bending does not change the length, that is, no strain) is d 1 、d 2 , and the strains after bending are ε 1 , ε 2 , the length before bending is L, and the bending radius is R, then:

[0047] L 1 =(1+ε 1 )L (0-17)

[0048] L 2 =(1+ε 2 )L (0-18)

[0049] The geometric relationship is:

[0050...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com