Full-diameter rock core hydrofracturing ultrasonic detection method with independent axial stress loading

A full-diameter core and independent loading technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems that rock distortion or shear force state cannot be simulated, and it is not a certain value. Achieve high creativity, satisfy horizontal resolution, and design scientific and reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

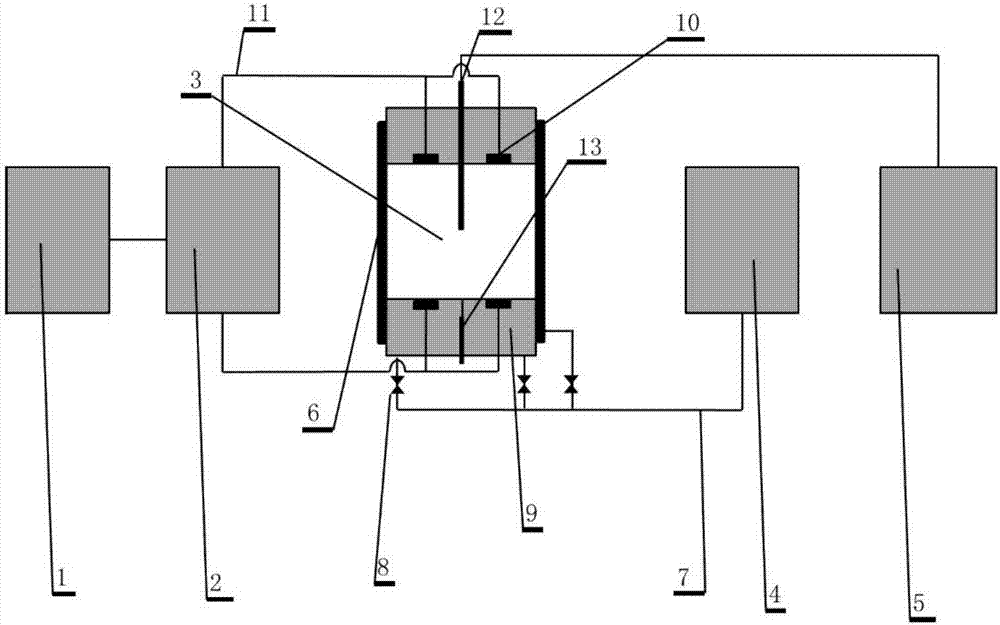

[0032] A full-diameter rock core hydraulic fracturing ultrasonic detection system independently loaded by axial stress, including a core holder 3, an ultrasonic detection system, a hydraulic loading system, and a fracturing fluid injection system.

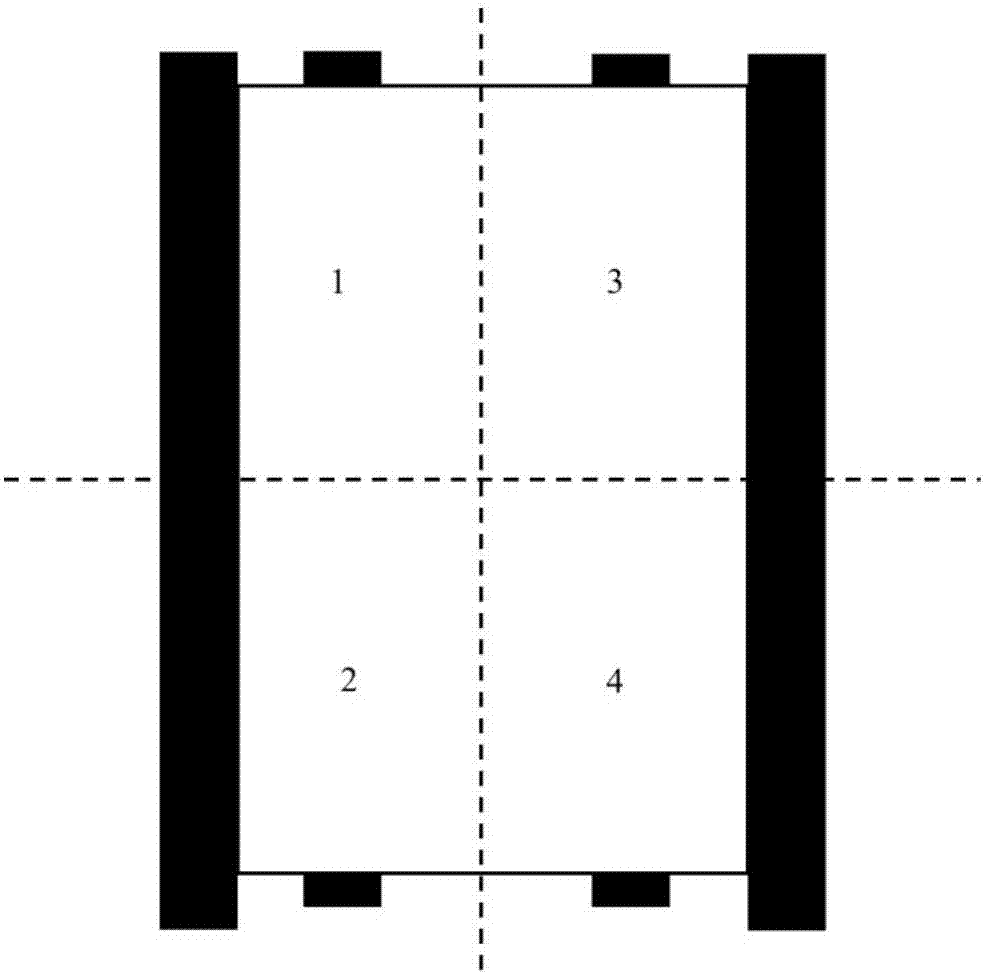

[0033] The ultrasonic testing system includes a computer 1, an oscilloscope 2, an ultrasonic signal cable 11 and an ultrasonic probe 10, the computer is connected to the oscilloscope, and the oscilloscope is connected to four ultrasonic probes through ultrasonic cables.

[0034] The fracturing fluid injection system includes an advection pump 5 and a fracturing fluid injection pipe 12, the advection pump is connected to the fracturing fluid injection pipe,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com