Device and method for carrying out liquid-phase pre-lithiation treatment on silicon monoxide negative electrode material

A negative electrode material, silicon oxide technology, applied in battery electrodes, electrochemical generators, structural parts, etc., can solve the problems of reduced lithium reducibility and potential safety hazards, and achieve reduced production costs, low processing temperature, and good economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

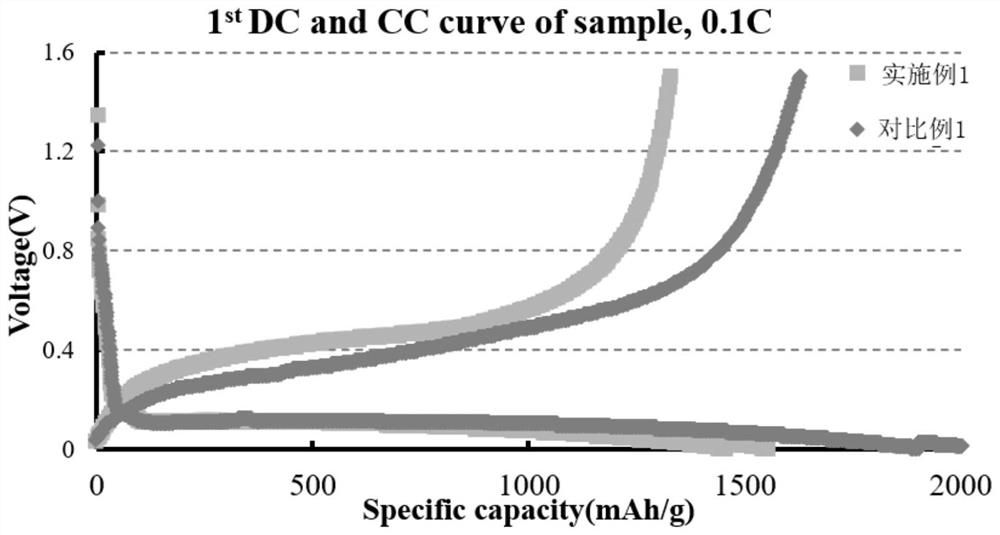

Embodiment 1

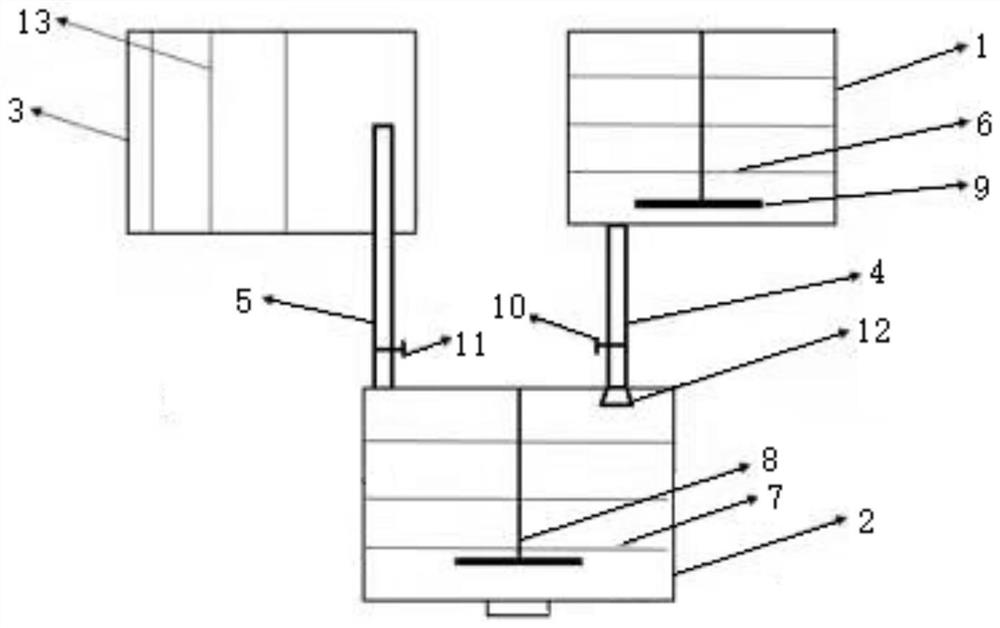

[0032]Get 2kg SiO (D50=6um) and add in mixing kettle 2, open the first stirring paddle 8, open the second heating device 7 to heat, keep the temperature at 190 ° C, and store in vacuum, the first locking valve 10 and the second locking Valve 11 remains closed. Add diphenyl ether and 105g of lithium ingot to the solvent kettle 1, quickly vacuumize, turn on the first heating device 6 to heat, and turn on the second stirring paddle 9 to stir, heat to 190 ° C, keep the temperature for 3 hours, and open the first locking valve. 10. Lithium in molten state is dispersed in diphenyl ether, and then through the first pipeline 4, under the action of the nozzle 12, the diphenyl ether dispersed with lithium is evenly touched and sprinkled on the SiO precursor in the mixing kettle 2, and the solvent is After the material in the kettle 1 is touched and sprinkled, the first locking valve 10 is closed. After the first stirring paddle stirring paddle 8 is continuously stirred at 190 ° C for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com