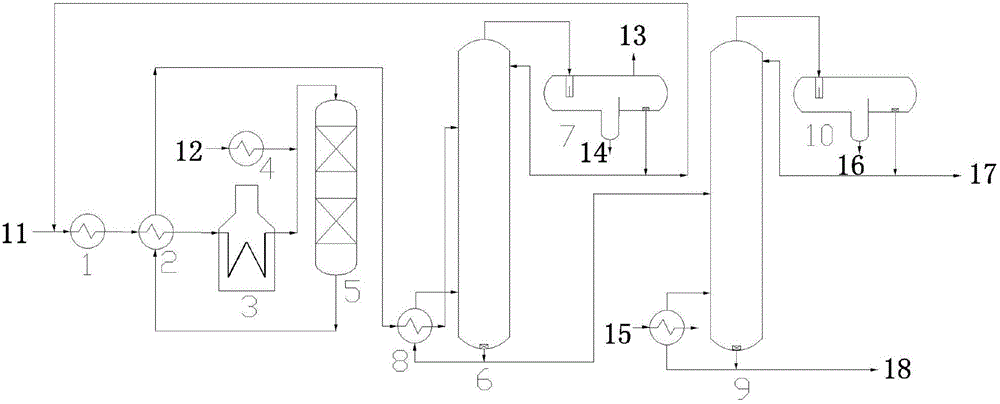

Method and device for preparing dimethylbenzene by alkylating benzene, methylbenzene and methanol

A technology of xylene and alkylation, which is applied in the production of xylene by the alkylation of toluene and methanol. From the field of benzene, it achieves the effects of easy operation, smooth process and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Benzene is used alone as raw material, and xylene is produced by alkylation reaction with methanol. The molar ratio of fresh raw materials to recycled raw materials is 1:3-6, the molar ratio of total benzene and toluene raw materials to methanol is 4-8:1, the reaction pressure is 0.5-0.6Mpa, the temperature is 400-450°C, and the total weight of raw materials The space velocity is 0.5-1h-1, and the xylene that meets the 3°C mixed xylene product standard in the "National Standard for Petroleum Mixed Xylene" (GB / T3470-2010) is produced.

Embodiment 2

[0050] The mixed feed of benzene and toluene is used for alkylation reaction with methanol to produce xylene. The molar ratio of toluene and benzene in fresh raw materials is 1:1, the molar ratio of fresh raw materials and recycled raw materials is 1:2-4, the molar ratio of total raw materials and methanol is 3-5:1, and the reaction pressure is 0.5-0.6Mpa , the temperature is 400-450°C, the total space velocity of the raw material weight is 1-2h-1, and the xylene that meets the 3°C mixed xylene product standard in the "National Standard for Petroleum Mixed Xylenes" (GB / T3470-2010) is produced.

Embodiment 3

[0052] The mixed feed of benzene and toluene is used for alkylation reaction with methanol to produce xylene. The molar ratio of toluene and benzene in fresh raw materials is 2:1, the molar ratio of fresh raw materials and recycled raw materials is 1:1-2, the molar ratio of total raw materials and methanol is 2-4:1, and the reaction pressure is 0.5-0.6Mpa , the temperature is 400-450°C, the total space velocity of the raw material weight is 2-3h-1, and the xylene that meets the 3°C mixed xylene product standard in the "National Standard for Petroleum Mixed Xylenes" (GB / T3470-2010) is produced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com