Stress corrosion experimental method for full-scale marine oil and gas pipeline

An oil and gas pipeline, stress corrosion technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of lack of bending moment load application function, limitation of load types, etc., to achieve the effect of improving experimental efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with accompanying drawing, the specific embodiment of the present invention will be further described:

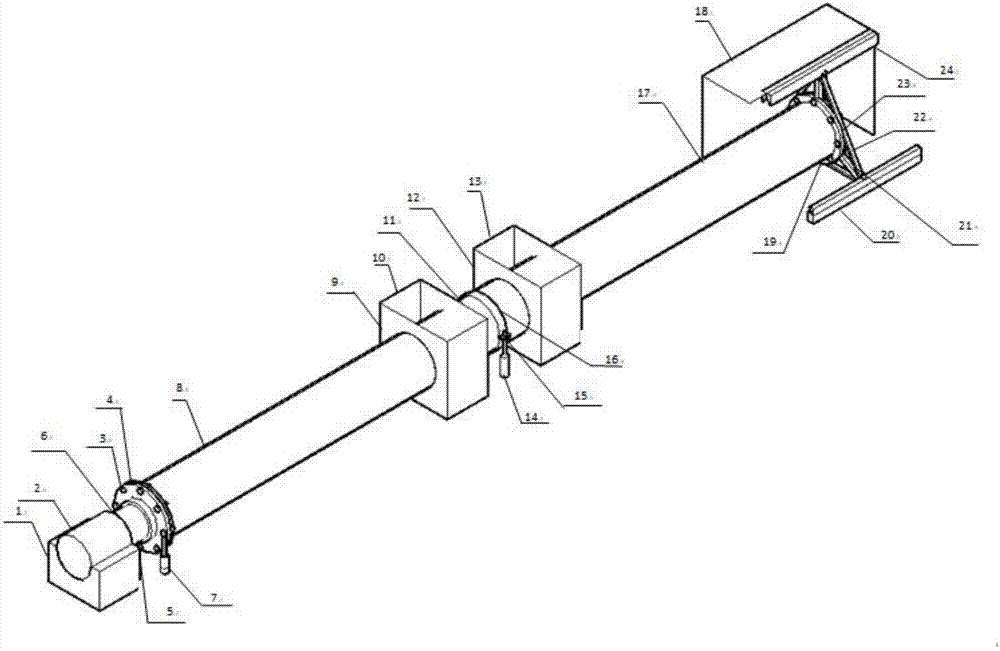

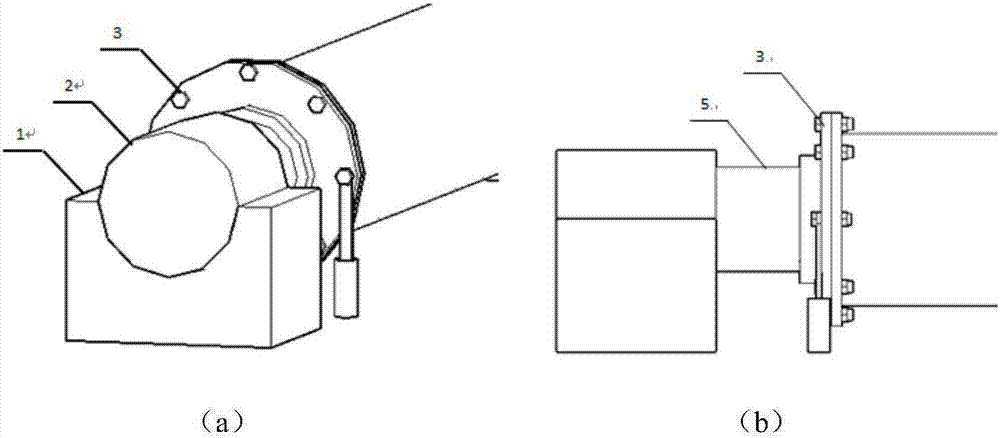

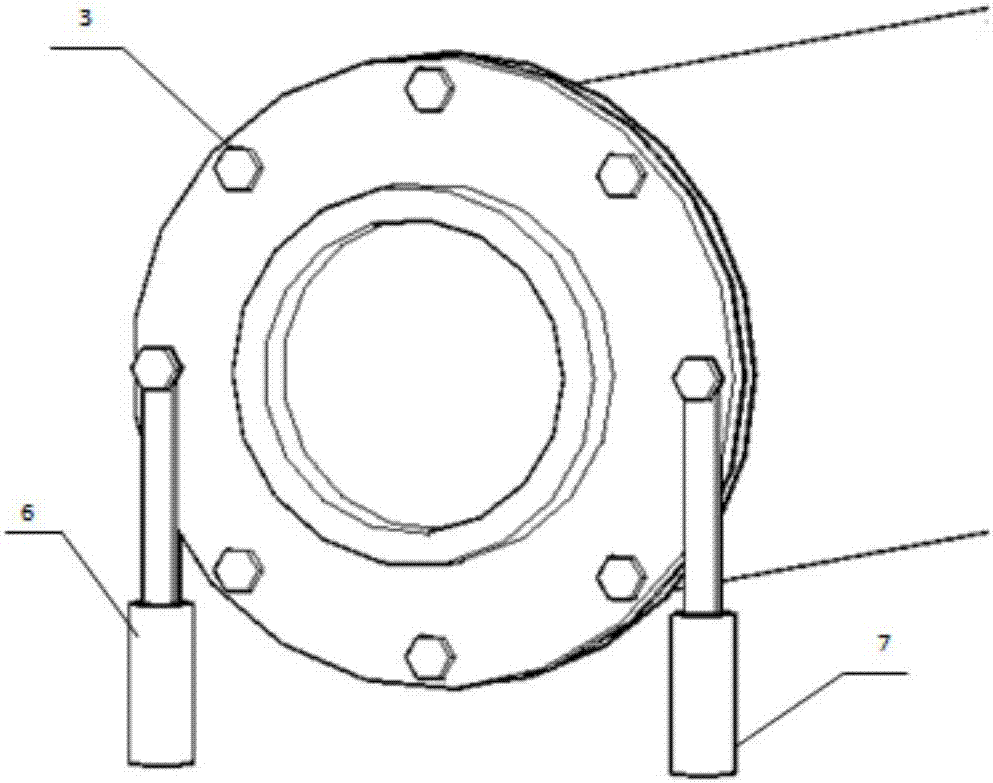

[0044] Such as figure 1 As shown, the full-scale marine engineering pipeline corrosion test equipment is mainly used to measure the state change of the full-scale experimental pipeline 8 in the seawater corrosion solution under the condition of applying complex loads, including: axial load loading devices 1, 2, 5. Torsional load loading devices 6, 7, bending load loading devices 11, 14, 15, 16, corrosion experiment water tanks 9, 10, 12, 13, pipeline fixing devices 17, 19, 20, 21, 22, 23, 24, The experimental equipment fixes the thermal insulation outer wall 18 . Among them, the corrosion test water tank 10 and the corrosion test water tank 13 are sealed and connected to the test pipeline 8 through anti-corrosion rubber gaskets, the test pipeline 8 is connected to the axial load and torsional load loading device through the flange 3 and the flan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com