Built-in very-high-frequency partial discharge detection device and method

A technology of partial discharge detection and very high frequency, which is applied in the field of high voltage electricity, can solve the problems of inability to realize real-time online monitoring of cable faults in time, inability to support signal acquisition, and non-fixed installation, etc., so as to improve accuracy and optimize installation location , the effect of eliminating interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

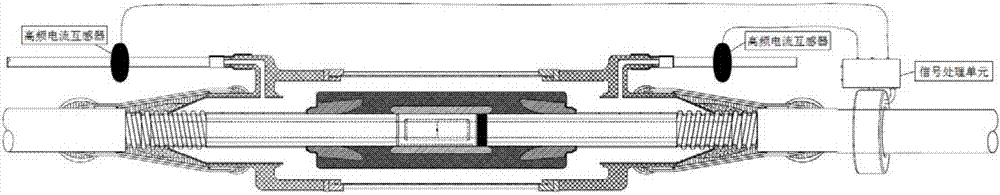

[0032] In the prior art, the cable joint is usually a high-incidence area of partial discharge, which is the weakest link that affects the overall cable work; the traditional HFCT method for partial discharge detection is high-frequency signal detection. Such as figure 1 As shown in the schematic diagram of the traditional cable partial discharge signal detection device, the traditional partial discharge detection device, the high-frequency current transformer is placed on the grounding cable, and the frequency supported by the HFCT is 1M to 20M. In the prior art, there is a certain distance between the cable joint and the grounding cable outside the cable, usually more than 1 meter, and the partial discharge signal is attenuated into a high-frequency signal (between 5 and 15M) due to the inductive effect of the grounding cable of the cable. It is meaningless to use very high frequency detection; since the frequency response of HFCT current transformer is between 1 and 20M, it...

Embodiment 2

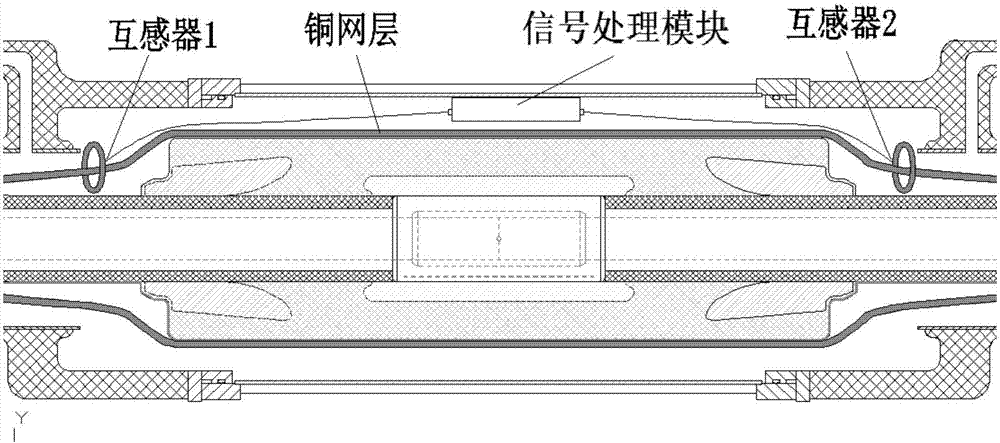

[0058] A built-in very high frequency (VHF) partial discharge detection device, the device includes a VHF current transformer, a signal acquisition module, and a signal processing module, and the VHF current transformer and signal acquisition module are installed inside the copper shell of the cable joint And through the signal line, it is connected with the signal processing module placed outside the copper shell of the cable joint.

[0059] In the built-in VHF partial discharge detection device described in the embodiment of the present invention, the VHF current transformer is a VHF current transformer made of nickel-zinc ferrite. The VHF current transformer can also be a VHF current transformer based on the Rogowski coil method. The frequency response of the VHF current transformer is 10M to 50M.

[0060] In the built-in very high frequency (VHF) partial discharge detection device described in the embodiment of the present invention, the sampling rate of the signal acquis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com