Seed epitaxial growth-based controllable preparation method of single crystal gold@platinum core-shell octahedral nanoparticle

A nanoparticle and octahedral technology, which is applied in the field of controllable preparation of gold@platinum core-shell octahedral nanoparticles, can solve the problems of mismatching and immiscibility between the lattices of gold and platinum, and achieve uniform size, good stability, and high yield. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

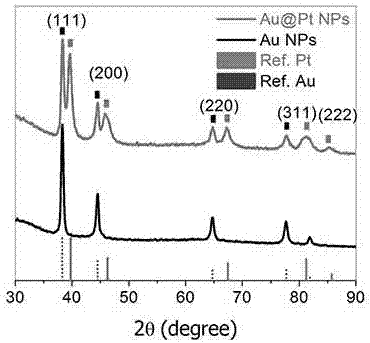

[0026] Preparation of gold@platinum core-shell octahedral nanoparticles with different platinum shell thickness

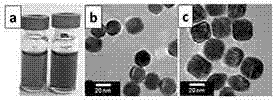

[0027] Preparation of 20 nanometer gold octahedral nanoparticles: Add polydiallyldimethylammonium chloride aqueous solution to 80 ml of ethylene glycol solution, stir well and then add chloroauric acid and sodium hydroxide aqueous solution to obtain prepared gold For the reaction precursor solution of octahedral nanoparticles, heat the reaction precursor solution in an oil bath at 200 degrees Celsius, react for 30 minutes, and cool naturally to room temperature to obtain the following: figure 1a (left) shows the colloidal solution of red gold octahedral nanoparticles with a particle size of 20 nm, such as figure 1 As shown in b, the concentrations of polydiallyldimethylammonium chloride, chloroauric acid, and sodium hydroxide in the reaction precursor are 0.02 mol / L, 0.0005 mol / L, and 0.0015 mol / L, respectively.

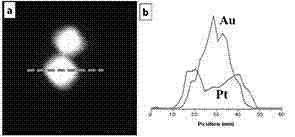

[0028] Gold@platinum core-shell octahedral nanopar...

Embodiment 2

[0030] Preparation of gold@platinum core-shell octahedral nanoparticles at 150°C: under stirring at room temperature, add 0.015 g of platinum acetylacetonate to 70 ml of prefabricated gold octahedral nanoparticle colloids with an electronic balance, stir magnetically for 30 minutes, and transfer After demagnetization, place the obtained mixed solution of platinum acetylacetonate and gold octahedral nanoparticles in an oil bath at 150 degrees Celsius for reaction. The color of the solution gradually changes from red to brown, and the reaction stops after 60 minutes. Take it out of the oil bath and let it cool naturally. After reaching room temperature, use a high-speed centrifuge at a speed of 14,000 rpm for 60 minutes, remove the colorless solution in the centrifuge tube to obtain a brown precipitated product; then ultrasonically clean the precipitated product with deionized water to obtain a product similar to Figure 8 The shown hybrid product of gold@platinum core-shell octa...

Embodiment 3

[0032] Gold@platinum core-shell octahedral nanoparticles obtained under the condition that the molar ratio of platinum to gold is 2:1: under the condition of stirring at room temperature, take 0.03 g of platinum acetylacetonate with an electronic balance and add it to 70 ml of prefabricated gold octahedral nanoparticle colloids, After magnetic stirring for 45 minutes, the magnet was removed, and the obtained mixed solution of platinum acetylacetonate and gold octahedral nanoparticles was placed in an oil bath at 230 degrees Celsius for reaction. The color of the solution gradually changed from red to brown, and the reaction stopped after 30 minutes. Take it out from the oil bath, cool it down to room temperature naturally, and centrifuge at a speed of 14,000 rpm for 60 minutes with a high-speed centrifuge, remove the colorless solution in the centrifuge tube to obtain a brown precipitated product; then ultrasonically clean the precipitated product with deionized water to prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com