Compound gallium nitride based semiconductor growing substrate and producing method thereof

A gallium nitride-based, growth substrate technology, applied in crystal growth, semiconductor devices, chemical instruments and methods, etc., can solve the problems of difficulty in widespread commercialization, high hardness and price, and reduced luminous efficiency of light-emitting devices. cost, quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

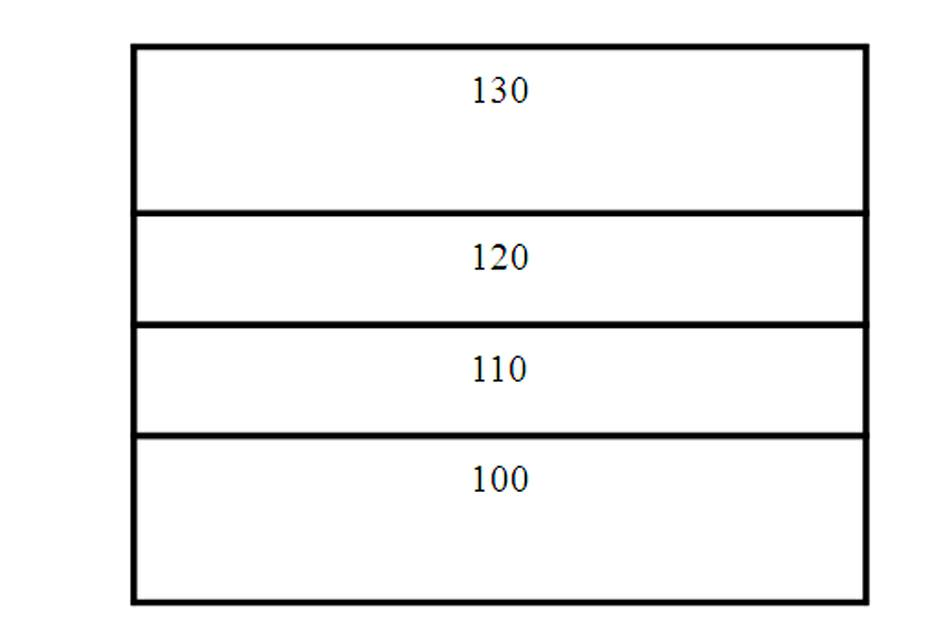

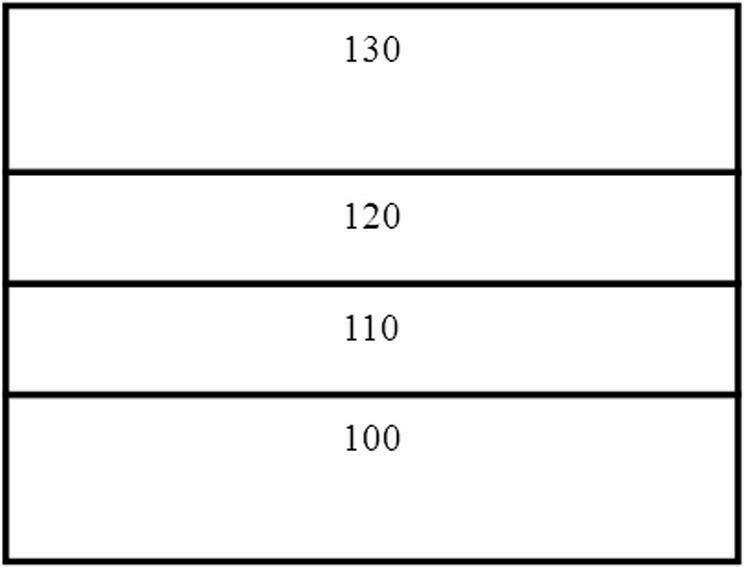

[0018] Such as figure 1 As shown, the GaN-based material layer 130 is epitaxially grown on a compound gallium nitride-based semiconductor growth substrate based on quartz glass. The composite growth substrate includes: quartz glass 100, as the substrate of the composite growth substrate; the diamond-like film layer 110 is formed on the quartz glass as a lattice buffer layer, and its material can be Si-DLC film, C- The thickness of the DLC film, Ni-DLC or titanium carbide-DLC is 1-10000 nm; the lattice conversion layer 120 is formed on the lattice buffer layer 110 . The lattice coefficient of the lattice conversion layer is between GaN and diamond-like thin films, which matches with gallium nitride-based semiconductor materials, and nitrides (such as aluminum nitride, aluminum gallium nitride, gallium nitride, gallium nitride, etc.) can be used Indium, indium nitride or aluminum gallium indium nitride), in this embodiment, aluminum nitride (AlN) is used, with a thickness of 10...

Embodiment 2

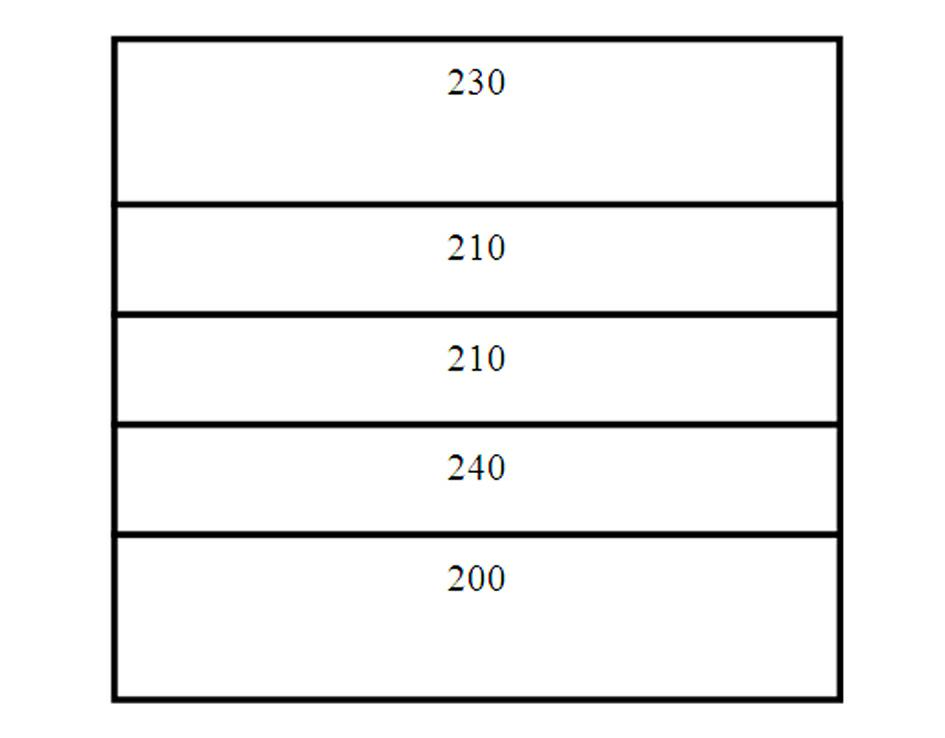

[0025] The difference from Embodiment 1 is that this embodiment uses a metal substrate as the base of the composite growth substrate, and a seed layer 240 is added between the metal substrate 200 and the lattice buffer layer 210, which acts as an epitaxy The use of the substrate enables the GaN-based material to grow smoothly through the seed layer.

[0026] Such as figure 2 As shown, the GaN-based material layer 230 is epitaxially grown on a composite GaN-based semiconductor growth substrate based on a metal substrate. The composite growth substrate includes: a metal substrate 200 , a seed layer 240 , a lattice buffer layer 210 composed of a diamond-like film, and a lattice conversion layer 220 .

[0027] The melting point of the metal substrate 200 is preferably higher than 1000°C, and a tungsten carbide substrate, tungsten substrate, silicon carbide or steel substrate can be used. The seed layer 240 is located on the metal substrate, and its material can be chromium, tit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com