Preparation and application of extremely high temperature resistant non-gelatinization egg liquid

A technology of gelling egg liquid and high temperature resistance, applied in the field of denatured protein, can solve the problems of not being eliminated, limiting the degree of protein hydrolysis, short shelf life, etc., and achieving the effects of enhanced storage, improved nutrition, and low microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

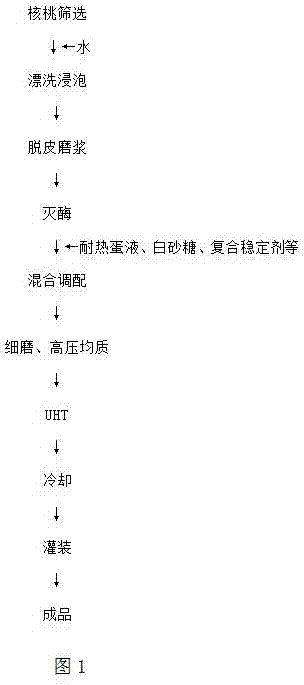

Method used

Image

Examples

Embodiment 1

[0029] Weigh 500g of egg liquid, put it in a container, adjust the pH value to 7.4 with 10% sodium carbonate solution, heat it in a water bath to 60°C, add neutral protease 5U / 100g, and react for 0.5h with 10% lemon Adjust the reaction pH to 3.5 with acid in time to inhibit the reaction of neutral protease, add carboxypeptidase to react for 4 hours, adjust the pH value to 8.0 with 10% NaOH solution, heat to extinguish the enzyme, 85°C for 1 hour, cool to obtain a semi-finished product .

Embodiment 2

[0031] Weigh 500g of egg liquid, put it in a container, adjust the pH value to 8.7 with 10% NaOH solution, heat it in a water bath to 40°C, add neutral protease 5U / 100g, and carry out the reaction. The reaction temperature is 60°C, and the reaction time is 2h. The pH value of the 10% citric acid solution reaction is 3.5, continue to carry out the carboxypeptidase reaction for 4 hours, neutralize, inactivate the enzyme, and cool to obtain a semi-finished product.

Embodiment 3

[0033] Weigh 500g of egg liquid, put it in a container, adjust the pH value to 8.2 with 10% citric acid solution, heat it in a water bath to 60°C, add 1U / 100g of neutral protease, and carry out the reaction. The reaction temperature is 55°C, and the reaction time is 1h. The pH value of the reaction with 10% citric acid solution is 3.5, continue the carboxypeptidase reaction for 4 hours, neutralize, inactivate the enzyme, and cool to obtain a semi-finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com