Metallic binding agent, diamond grinder and diamond grinder preparation method

A metal bond and diamond technology, which is applied in metal processing equipment, grinding/polishing equipment, abrasives, etc., can solve the problems of not describing the service life and grinding effect of abrasive tools, complex preparation process, etc., and achieve good self-sharpening , the effect of firm combination and easy access to materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

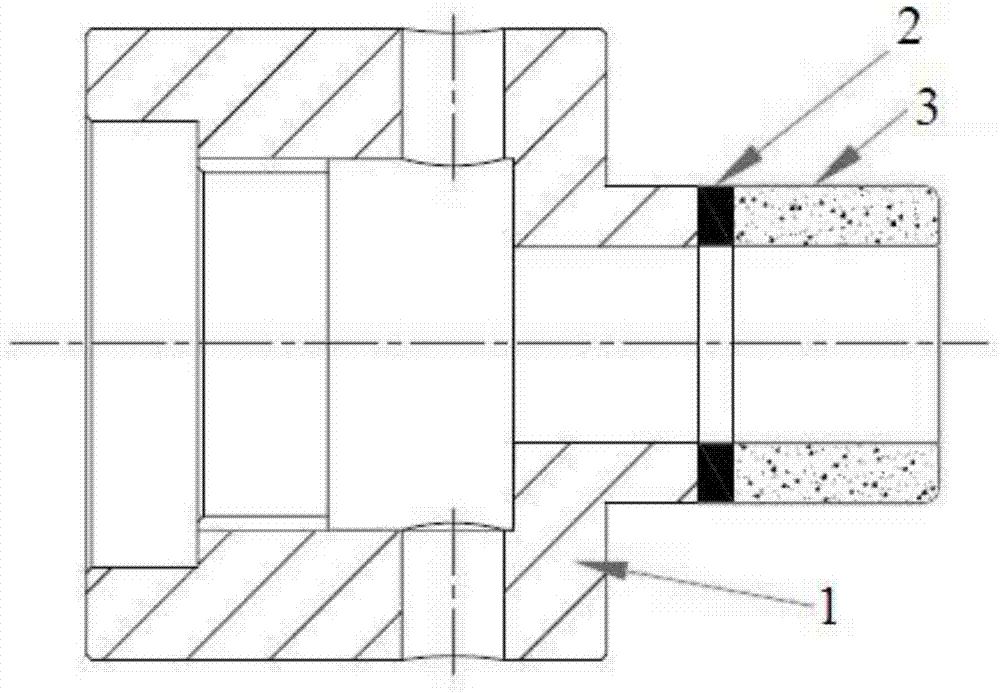

Image

Examples

Embodiment 1

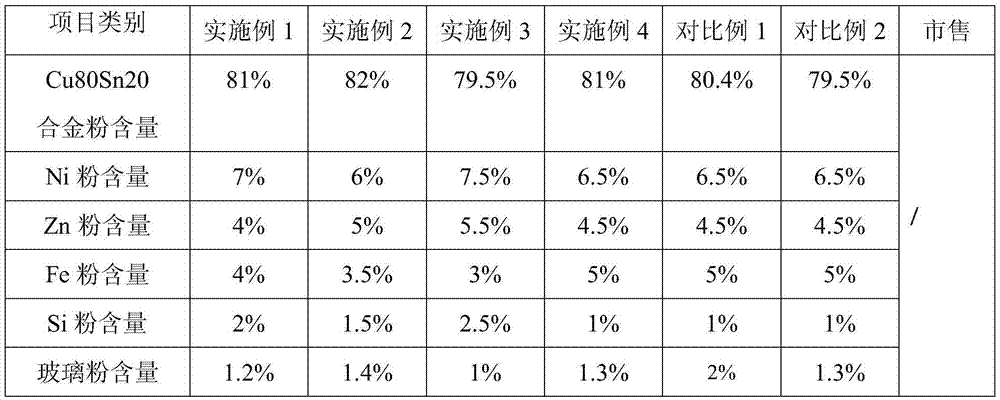

[0034] A kind of metal bonding agent, is made up of the raw material of following weight part:

[0035] Cu80Sn20 alloy powder 81 parts; Ni powder 7 parts; Zn powder 4 parts; Fe powder 4 parts; Si powder 2 parts; glass powder 1.2 parts; graphite powder 0.8 parts.

Embodiment 2

[0037] A kind of metal bonding agent, is made up of the raw material of following weight part:

[0038] Cu80Sn20 alloy powder 82 parts; Ni powder 6 parts; Zn powder 5 parts; Fe powder 3.5 parts; Si powder 1.5 parts; glass powder 1.4 parts; graphite powder 0.6 parts.

Embodiment 3

[0040] A kind of metal bonding agent, is made up of the raw material of following weight part:

[0041] Cu80Sn20 alloy powder 79.5 parts; Ni powder 7.5 parts; Zn powder 5.5 parts; Fe powder 3 parts; Si powder 2.5 parts; glass powder 1 part; graphite powder 1 part.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com