Open-width continuous washing system

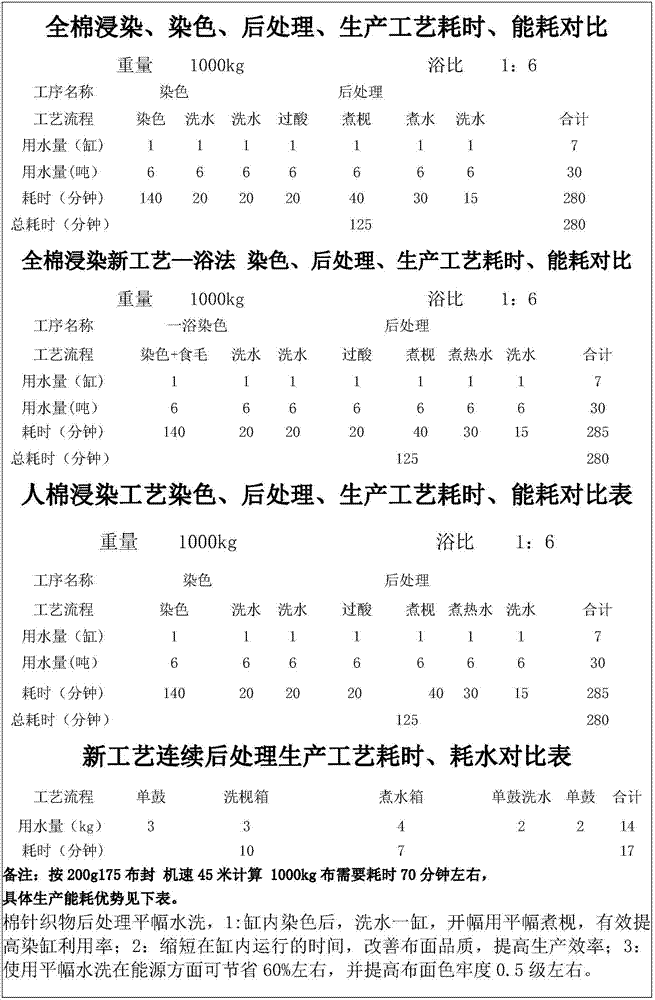

A technology of open-width water washing and water washing machine, which is applied in the continuous processing of textile materials, textile and papermaking, liquid/gas/vapor removal with squeeze rollers, etc. The fabric is easy to be scratched and other problems, to meet the requirements of the washing process, the effect of water saving and emission reduction is obvious, and the production efficiency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further clarified below in conjunction with the accompanying drawings, tables and specific examples.

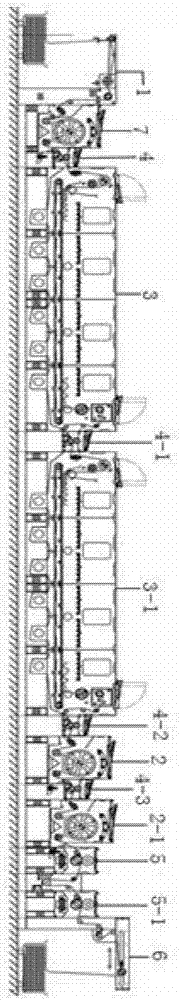

[0015] Such as figure 1 A kind of continuous open-width water washing system shown is composed of a cloth feeding assembly 1, a washing machine 7, a first washing water tank 3, a second washing water tank 3-1, a first washing water single drum box 2, a second washing water tank The washing water single drum box 2-1 and the cloth output assembly 6 are composed; the cloth feeding assembly 1 includes the cloth feeding and stacking groove, the thread separation roller and the cloth feeding and centering device; the washing machine 7 is a single drum washing machine; the first The washing water tank 3 and the second washing water tank 3-1 are mesh belt type soaping tanks respectively; the first washing water single drum box 2 and the second washing water single drum box 2-1 are respectively two-roll padding car washing tanks; Component 6 is an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com