Automatic control method for biomass suspension combustion furnace

A technology of suspended combustion and biomass, applied in the direction of controlling combustion, lighting and heating equipment, etc., to improve control accuracy and response speed, realize intelligent control, and improve heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

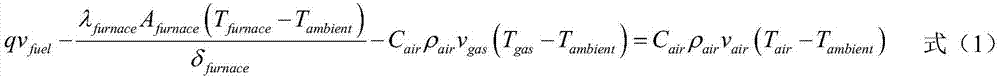

Method used

Image

Examples

Embodiment 1

[0044] A rice husk suspension combustion furnace for heating air, and an array of 10×10 steel pipes with a diameter of 10 cm and a length of 30 cm is arranged at the flue opening of the furnace. The high-temperature exhaust gas generated by combustion passes through the gaps between the steel pipe arrays, and the cold air passes through the steel pipes, and the two complete heat exchange.

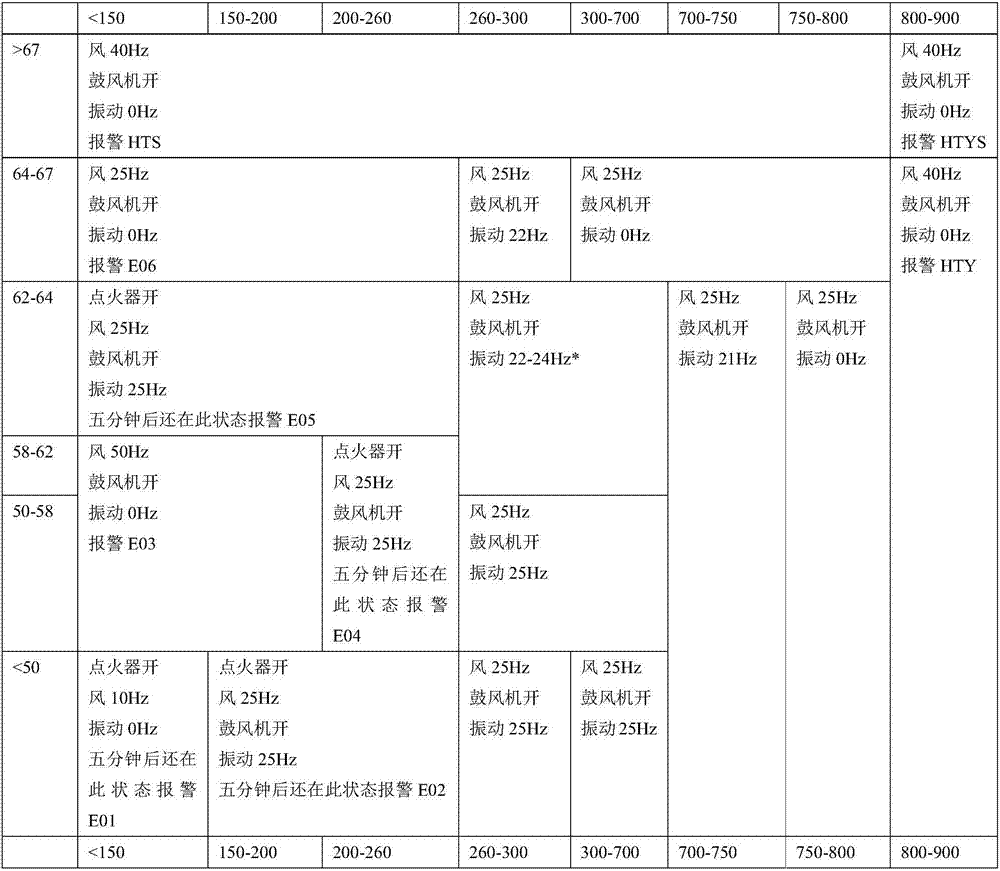

[0045] For this combustion furnace, when applying the automatic control method of the biomass suspension combustion furnace of the present invention, the input includes the flue temperature and the gas outlet temperature (hot air temperature), wherein the flue temperature is used as the horizontal coordinate axis, and the gas outlet temperature is used as the ordinate Axis; input amount, that is, in the operation of setting each state area of the N-dimensional coordinate system, the biomass feed motor is a vibration motor, and the biomass feed amount is determined by the operating freque...

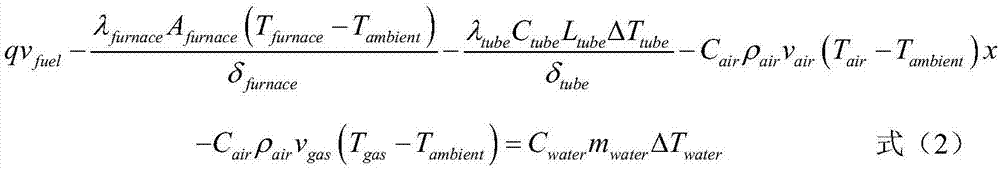

Embodiment 2

[0062] A rice husk suspension combustion furnace using water as heat transfer medium. The circulating water passes through the interlayer outside the furnace, and the high-temperature exhaust gas generated by combustion exchanges heat with the circulating water.

[0063] For this kind of combustion furnace, when applying the automatic control method of the biomass suspension combustion furnace of the present invention, the input includes flue temperature and water outlet temperature, wherein the flue temperature is used as the horizontal axis, and the water outlet temperature is used as the vertical axis. Input amount, that is, in the operation of setting each state area of the N-dimensional coordinate system, the biomass feeding motor is a vibration motor, and the biomass feeding amount is determined by the operating frequency of the vibration motor. The higher the frequency, the faster the feeding speed , the larger the feeding amount, the induced air volume should be incr...

Embodiment 3

[0071] A rice husk suspension combustion furnace using water as heat transfer medium. The circulating water passes through the interlayer outside the furnace, and the high-temperature exhaust gas generated by combustion exchanges heat with the circulating water.

[0072] For this combustion furnace, when applying the automatic control method of the biomass suspension combustion furnace of the present invention, the input includes flue temperature, water outlet temperature and water inlet temperature, wherein the flue temperature is used as the horizontal axis, and the water outlet temperature is used as the vertical axis , the temperature of the water inlet is used as the third-dimensional coordinate axis; the input amount, that is, in the operation of setting each state area of the N-dimensional coordinate system, the biomass feeding motor is a vibration motor, and the biomass feeding amount is determined by the operating frequency of the vibration motor It is determined th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com