High-repetition-frequency compact type industrial-level mode-locking optical fiber laser

A fiber laser, high repetition rate technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problems of laser self-starting difficulties, low mode-locking start-up threshold, etc., to improve self-starting difficulties, low lock-in The effect of modulating the start-up threshold, improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

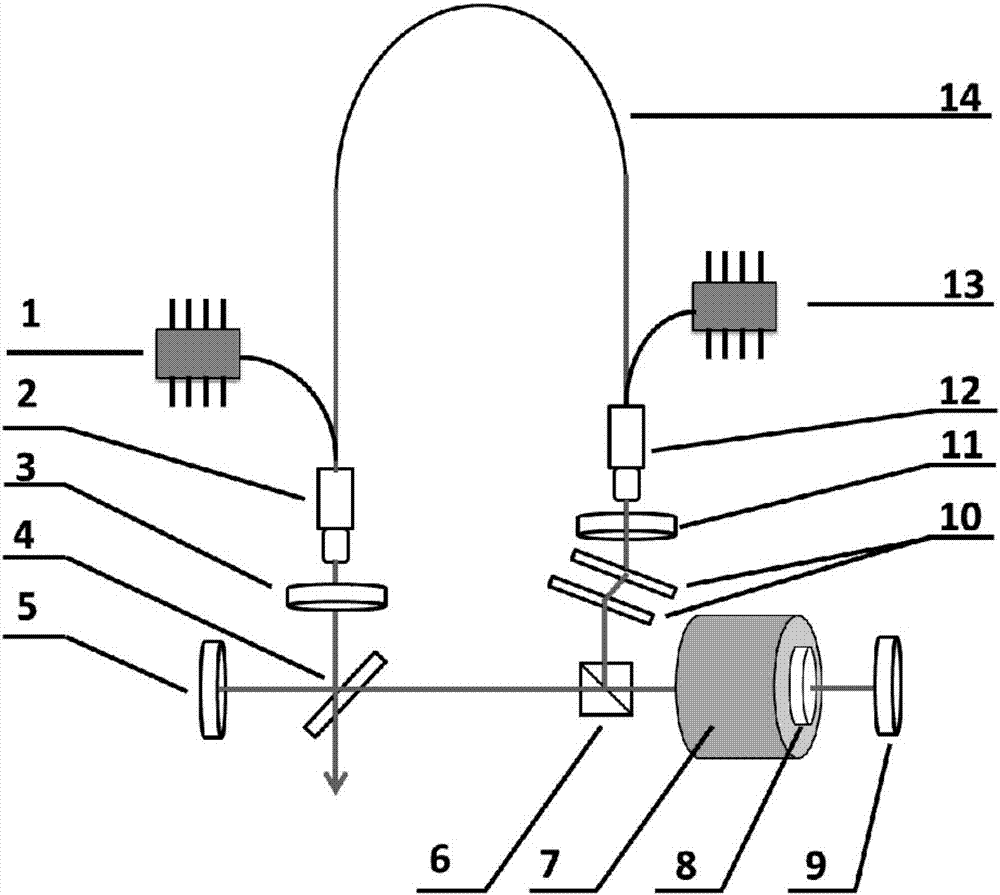

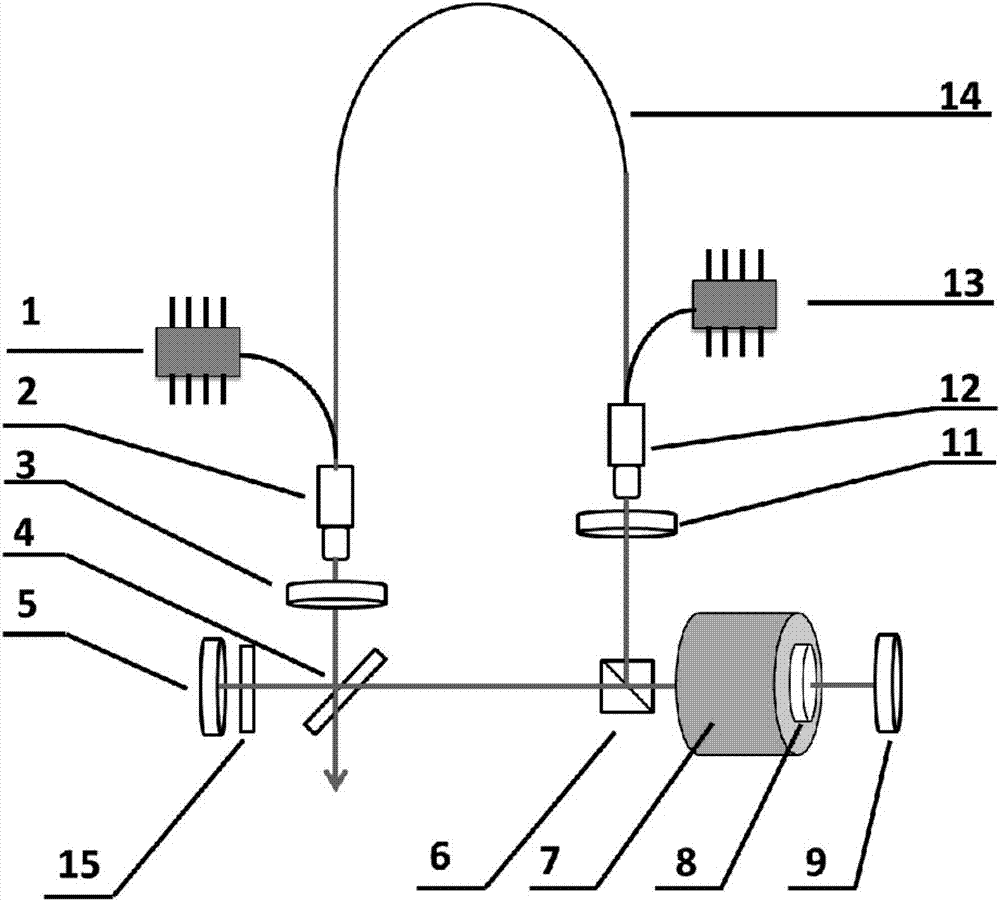

[0020] Such as figure 1 or figure 2 As shown, a high repetition rate compact industrial-grade mode-locked fiber laser includes a first pump source 1, a first wavelength division multiplexing collimator 2, a first half-wave plate 3, a beam splitter Device 4, first reflector 5, polarization beam splitter cube 6, Faraday rotator 7, one-eighth wave plate 8 on Faraday rotator 7, second reflector 9, grating pair (10), second half A wave plate 11, a second wavelength division multiplexing collimator 12, a second pumping source 13, and an optical fiber 14; the output end of the first pumping source 1 is connected to the first wavelength division multiplexing collimator The wavelength division multiplexing input terminal of 2 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com