High-gluten whitened additive-free instant wrappers and quick preparation process

A high-gluten whitening and preparation technology, which is applied in food ingredients as thickeners, food science, food preservation, etc., can solve the tedious process of noodle washing, the taste and color of dough, and reduce cooking time, ensure flavor, and change The effect of rehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

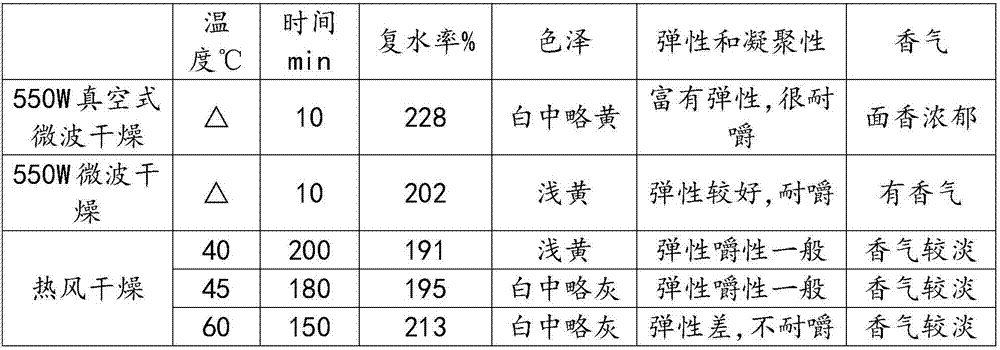

Image

Examples

Embodiment 1

[0022] A high-gluten whitening instant noodle without additives, comprising the following ingredients: 10kg of flour, 0.4g of Aspergillus oryzae protease, 0.1g of lipoxygenase, 150g of acetate starch, 200g of soybean protein isolate, 20g of table salt, and 200g of salad oil.

[0023] Dough rehydration test: Weigh 10g of instant noodles, put them in a 1000mL insulated container with a cover, add boiling water 7.5 times the weight of the dough, soak for 5min, filter and weigh 35.1g of the dough, and the rehydration rate is 251%.

[0024] A rapid preparation process of high-gluten whitening instant noodle without additives, the preparation steps are as follows:

[0025] (1) Flour mixing: put 10kg flour and 0.1g lipoxygenase into the material box, add 30kg water from the water inlet, adjust the temperature in the material box to 20°C, open the valve of the agitator, stir quickly and evenly, and then enzymatically hydrolyze 20min, then add 0.4g Aspergillus oryzae protease, adjust t...

Embodiment 2

[0029] A high-gluten whitening instant noodle without additives, comprising the following ingredients: flour 11kg, Aspergillus oryzae protease 0.6g, lipoxygenase 0.4g, phosphate monoester starch 200g, soybean protein isolate 300g, salt 25g, salad oil 300g.

[0030] Dough rehydration test: Weigh 15g of instant noodles, put them in a 1000mL insulated container with a cover, add boiling water 7.5 times the weight of the dough, soak for 5min, filter and weigh the quality of the dough to be 32.8, and the rehydration rate is 252%.

[0031] A rapid preparation process of high-gluten whitening instant noodle without additives, the preparation steps are as follows:

[0032] (1) Flour: put 11kg of flour and 0.4g of lipoxygenase into the material box, add 31kg of water from the water inlet, adjust the temperature in the material box to 30°C, open the valve of the agitator, stir quickly and evenly, and then enzymatically hydrolyze 30min, then add 0.6g Aspergillus oryzae protease, adjust t...

Embodiment 3

[0036] A high-gluten whitening instant noodle without additives, comprising the following ingredients: 12kg of flour, 0.7g of Aspergillus oryzae protease, 0.5g of lipoxygenase, 300g of hydroxypropyl starch, 500g of soybean protein isolate, 30g of table salt, and 400g of salad oil.

[0037] Dough rehydration test: Weigh 20g of instant noodles, put them in a 1000mL insulated container with a cover, add boiling water 7.5 times the weight of the dough, soak for 5min, filter and weigh 65.5% of the dough, and the rehydration rate is 228%.

[0038] A rapid preparation process for high-gluten whitening instant noodles without additives, the preparation steps are as follows:

[0039](1) Flour preparation: put 12kg of flour and 0.5g of lipoxygenase into the material box, add 32kg of water from the water inlet, adjust the temperature in the material box to 30°C, open the valve of the agitator, stir quickly and evenly, and then enzymatically hydrolyze 30min, then add 0.7g Aspergillus oryz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com