Hydroxyapatite nano peanut/gelatin self-assembled nano composite material and preparation method thereof

A nanocomposite material, hydroxyapatite technology, applied in the field of biomedical materials, can solve problems such as energy consumption, weak interaction between hydroxyapatite and gelatin, and nanostructure damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Take 0.5 g of hydroxyapatite nano-peanut powder, and super-disperse it in 10 mL of water for 0.5 minutes to make a uniformly dispersed hydroxyapatite dispersion, which is ready for use;

[0026] (2) Add 0.5g of gelatin powder to the hydroxyapatite dispersion obtained in the previous step, swell at room temperature for 1 hour, then heat to 65°C, stir until the gelatin is completely dissolved, and continue to stir and homogenize for 1 hour to prepare hydroxyapatite limestone / gelatin mixture, set aside;

[0027] (3) Pour the mixture in step (2) into the mold, concentrate in vacuum at 65°C to 50% of the original weight, cool to 35°C and keep it warm for 2 hours, put it into a freeze dryer at -2 to -5°C and freeze-dry Obtain hydroxyapatite nano-peanut / gelatin self-assembled nanocomposite;

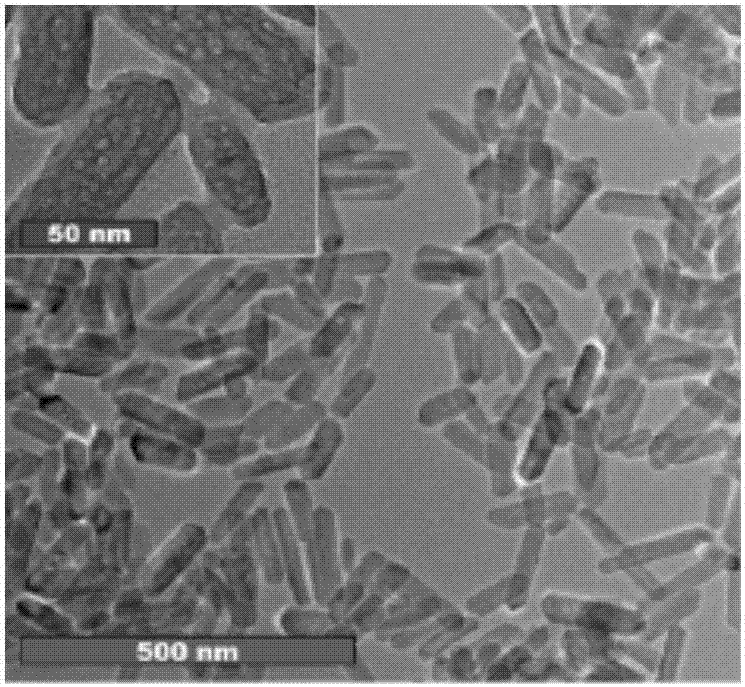

[0028] figure 1 This is the TEM photo of the hydroxyapatite nano-peanut used. The hydroxyapatite is in the shape of a nano-peanut, with a length of 50-210 nanometers and a width of ...

Embodiment 2

[0034] Increase the amount of hydroxyapatite nano-peanut powder in step (1) in Example 1 to 1 g, and the other steps are the same as in Example 1. Obtain product with embodiment 1.

Embodiment 3

[0036] The amount of hydroxyapatite nano-peanut powder in step (1) in Example 1 is reduced to 0.1 g, and other steps are the same as in Example 1. Obtain product with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com