Preparation method of ZnI2-I/ZnO composite with photocatalytic antibacterial function

A composite material and photocatalytic technology, which is applied in the field of photocatalytic nanomaterial synthesis, can solve the problem that the photocatalytic antibacterial activity cannot meet the actual requirements, achieve good antibacterial and sterilizing performance, mild preparation conditions, simple equipment and process easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

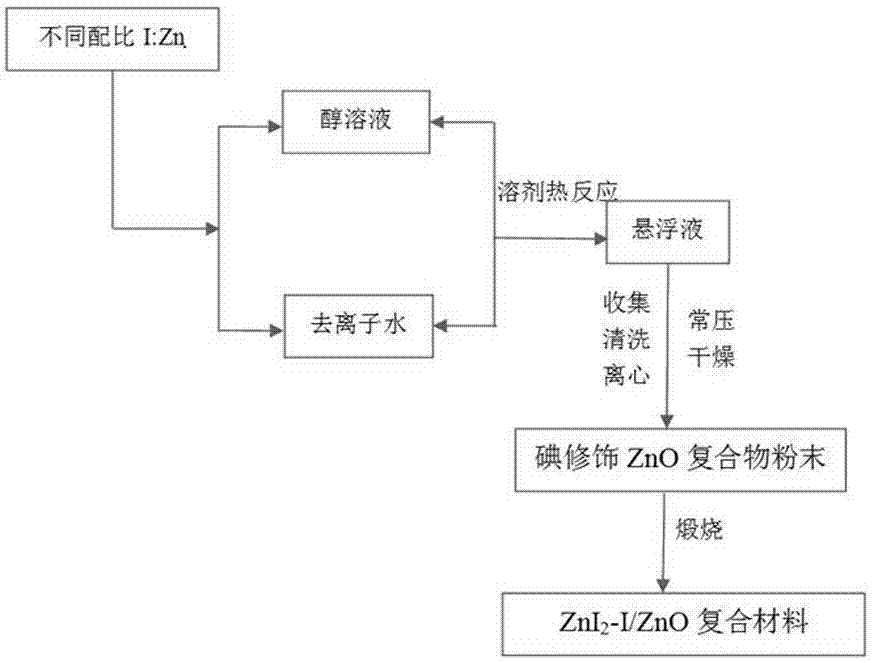

[0023] Preparation of ZnI with molar ratio I:Zn=1:4 2 -I / ZnO composite material

[0024] (1) 2.023g Zn(NO 3 ) 2 ·6H 2 O was added to a round bottom flask of 100ml deionized water, stirred until homogeneous, then 0.3g HIO was added 3 , then poured 160 mL of ethylene glycol, refluxed in an oil bath at 120 °C for 9 h, and then refluxed in an oil bath at 140 °C for 7 h, and continued magnetic stirring during the reaction.

[0025] (2) Naturally cool to room temperature after the reaction, collect the obtained suspension, wash, centrifuge, and dry under normal pressure at 60°C to obtain a yellow iodine-modified zinc oxide composite powder, which is calcined at 400°C for 2 hours.

[0026] Visible light photocatalytic sterilization performance test

[0027] The light-induced bactericidal performance test of the sample is carried out according to the following steps: first, weigh 30 mg of the above-mentioned catalyst material of Example 1, add to 40 mL (10 8 cfu / mL) in E. coli s...

Embodiment 2

[0033] Preparation of ZnI with molar ratio I:Zn=1:2 2 -I / ZnO composite material

[0034] (1) 1.012g Zn(NO 3 ) 2 ·6H 2 O was added to a round bottom flask of 100ml deionized water, stirred until homogeneous, then 0.3g HIO was added 3 , then poured 160 mL of ethylene glycol, refluxed in an oil bath at 120 °C for 9 h, and then refluxed in an oil bath at 140 °C for 7 h, and continued magnetic stirring during the reaction.

[0035] (2) Naturally cool to room temperature after the reaction, collect the obtained suspension, wash, centrifuge, and dry under normal pressure at 60°C to obtain a yellow iodine-modified zinc oxide composite powder, which is calcined at 400°C for 2 hours.

[0036] Visible light photocatalytic sterilization performance test

[0037] The light-induced bactericidal performance test of the sample is carried out according to the following steps: first, weigh 30 mg of the above-mentioned catalyst material of Example 2, add to 40 mL (10 8 cfu / mL) in E. coli s...

Embodiment 3

[0042] Preparation of ZnI with molar ratio I:Zn=1:6 2 -I / ZnO composite material

[0043] (1) 7.139g Zn(NO 3 ) 2 ·6H 2 O was added to a round-bottomed flask with 100ml of deionized water, stirred until uniform, then 0.599g of NaI was added, and then 160 mL of ethylene glycol was poured in, refluxed in an oil bath at 120°C for 9 h, and then refluxed in an oil bath at 140°C for 7 h, and the reaction Continuous magnetic stirring.

[0044] (2) Naturally cool to room temperature after the reaction, collect the obtained suspension, wash, centrifuge, and dry under normal pressure at 60°C to obtain a yellow iodine-modified zinc oxide composite powder, which is calcined at 400°C for 2 hours.

[0045] Visible light photocatalytic sterilization performance test

[0046] The light-induced bactericidal performance test of the sample is carried out according to the following steps: first, weigh 30 mg of the above-mentioned catalyst material of Example 3, add to 40 mL (10 8cfu / mL) in E....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com