Welding gun space attitude recognition method based on arc sensor

A technology of arc sensor and space attitude, which is applied in the direction of arc welding equipment, welding rod characteristics, welding equipment, etc., can solve the problems of limited space attitude of welding gun and difficult recognition of space attitude information, etc., achieve accurate recognition, avoid low recognition efficiency, and ensure The effect of efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

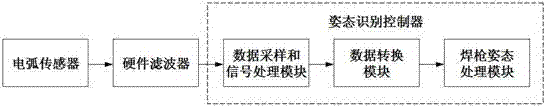

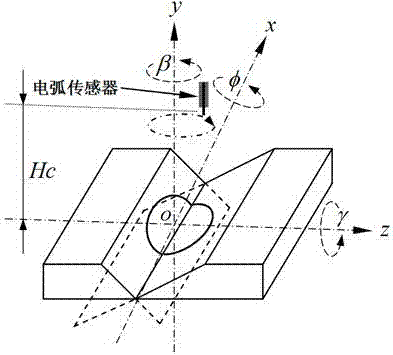

[0030] Embodiment 1: The system block diagram of a welding torch spatial posture recognition method based on an arc sensor in the present invention is as follows figure 1 As shown, it includes arc sensor, hardware filter, attitude recognition controller; the space attitude of arc sensor and weld bevel is as follows figure 2 As shown, in the welding process, the arc sensor scans the weld groove, collects the arc sensing signal reflecting the distance change of the welding torch in the weld groove scanning area relative to the workpiece weld, and passes the hardware filter to the arc sensing signal After filtering, it is sent to the attitude recognition controller. The attitude recognition controller includes a data sampling and signal processing module, a data conversion module, and a welding torch attitude processing module; through the data sampling and signal processing module, the output signal of the hardware filter is uniformly sampled and clipped and limited, and throug...

Embodiment 2

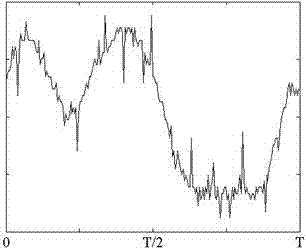

[0063] Embodiment 2: Through the method of the present invention, the arc sensor is used to scan the weld bevel during the welding process, and when welding under the welding torch space posture with deflection angle and roll angle, the output signal of the arc sensor is collected and passed through the hardware The output signal waveform after filtering by the filter is as follows: Figure 9 As shown, it can be seen that there are a small amount of pulse spikes in the arc signal;

[0064] The arc signal waveform after arc signal sampling and software filtering module processing is as follows: Figure 10 As shown, it not only eliminates and limits the pulse peak amplitude, but also maintains the overall characteristics of the original signal;

[0065] Through the data conversion module, the harmonic components containing the spatial attitude information of the welding torch are retained, and the arc signal harmonic waveform obtained after processing is as follows: Figure 11...

Embodiment 3

[0067] Embodiment 3: The present invention is also applicable to other spatial attitude recognition of welding torches based on welding seam groove scanning ranging sensors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com