Method for laser deep penetration-brazing connection of dissimilar material

A technology of dissimilar materials and laser welding joints, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of poor mechanical properties of joints, uneven spread of solder, and reduce radiation and absorption. Improved uniformity and reduced weld spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

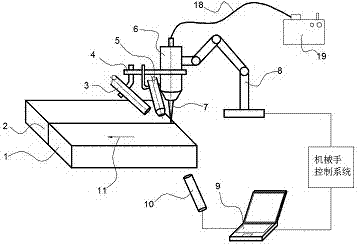

[0034] Such as figure 1 As shown, the laser welding system used in the embodiment of the present invention includes a laser generator 19, a transmission fiber 18, a welding manipulator 8, a laser welding head 6 that is connected to the laser generator 19 through the transmission fiber 18 and installed on the welding manipulator 8, a high-pressure gas Column nozzle 5 , protective gas nozzle 3 , temperature sensor 10 .

[0035] Both the high-pressure gas column nozzle and the shielding gas nozzle are connected with the laser welding head through the fixed bracket 4, so that the laser welding head, the high-pressure gas column nozzle and the shielding gas nozzle can move synchronously relative to the base metal, and the laser welding head, the high-pressure gas column nozzle and the The shielding gas nozzles are set to be aligned with the welding position.

[0036] The temperature sensor 10 is placed below the starting point of welding for real-time acquisition of the backside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com