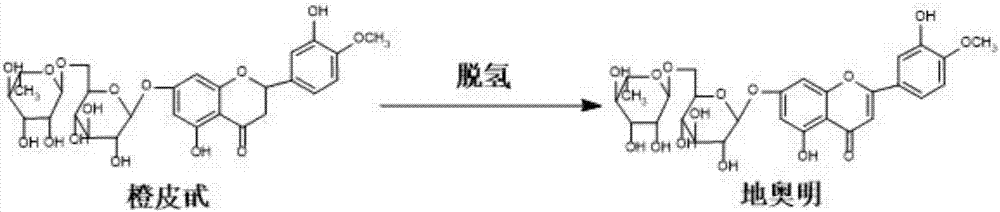

Diosmin production method based on dimethylsulfoxide system

A technology of dimethyl sulfoxide and production methods, which is applied in the direction of chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve problems such as large environmental pollution, and achieve short production cycle, low production cost, and reduced investment scale Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

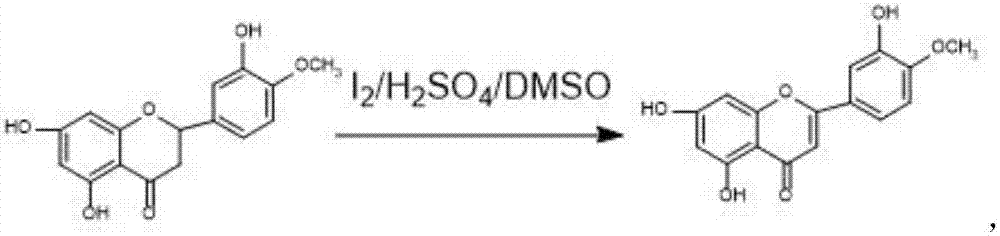

[0026] The diosmin production method based on the dimethyl sulfoxide system of the present invention comprises the following steps:

[0027] S1: Dissolve hesperidin and potassium iodide in dimethyl sulfoxide and put them into the first container, the ratio of the amount of potassium iodide to hesperidin is: 0.05-0.1:1.0, the hesperidin And the mass ratio with dimethyl sulfoxide is: 1.0-2.0:1.0;

[0028] S2: Add dimethyl sulfoxide and concentrated sulfuric acid into the second container, the mass ratio of dimethyl sulfoxide to hesperidin is 0.5:1.0, and the ratio of concentrated sulfuric acid to hesperidin is 0.1:1.0;

[0029] S3: The solution in the first container in step S1 and the solution in the second container in step S2 are fed and mixed into the reactor according to the volume ratio of the feed ratio of 2:1 to react, and the reaction temperature is 90-98 ° C, Cool down and collect the reaction solution after the reaction is complete;

[0030] S4: Transfer the reacti...

Embodiment 2

[0034] Based on Example 1, the mass ratio of potassium iodide to hesperidin in step S1 is 0.05:1.0, and the mass ratio of hesperidin to dimethyl sulfoxide is 1.0:1.0. Specifically include the following production steps:

[0035] (1) 12.5kg hesperidin and 0.17kg potassium iodide are dissolved in 12.5kg dimethyl sulfoxide and loaded into the A pump of the microreactor; (2) 6.25kg dimethyl sulfoxide is added to the B pump of the microreactor Sulfoxide and 0.2kg concentrated sulfuric acid; (3) Heat the reaction channel temperature of the microreactor to 90-98°C; (4) Adjust the feed ratio (volume: V / V) of the A pump and the B pump to 2:1 At the same time, the A pump and the B pump are turned on to mix and react, and the reaction residence time is controlled to be 6-10 seconds, and the temperature at the end of the reaction channel is controlled to 0-10°C to collect the reaction solution; In the reaction kettle, stir and control the temperature at 0-10°C, dropwise add methanol to p...

Embodiment 3

[0037] Based on Example 1, the mass ratio of potassium iodide to hesperidin in step S1 is 0.1:1.0, and the mass ratio of hesperidin to dimethyl sulfoxide is 2.0:1.0. The specific steps are as follows: (1) 12.5kg hesperidin and 0.34kg potassium iodide are dissolved with 6.25kg dimethyl sulfoxide and then loaded into the A pump of the microreactor; (2) 6.25 kg is added to the B pump of the microreactor. kg dimethyl sulfoxide and 0.2kg concentrated sulfuric acid; (3) heating the reaction channel temperature of the microreactor to 90-98°C; (4) adjusting the feed ratio (volume: V / V) of the A pump and the B pump 1 / 1, simultaneously turn on the A pump and the B pump to mix and react, and control the reaction residence time to be 6-10 seconds, and control the temperature at the end of the reaction channel to collect the reaction liquid at 0-10°C; Transfer the reaction solution to a reaction kettle, control the temperature at 0-10°C under stirring, add dropwise methanol to precipitate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com