Athletic field synthetic surface material and preparation method thereof

A technology for sports field and surface layer material, applied in the field of plastic materials, can solve the problems of high volatility of TDI, hazards, human and environmental hazards, etc., and achieve the effects of good shock absorption, improved comfort, and reduced fatigue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

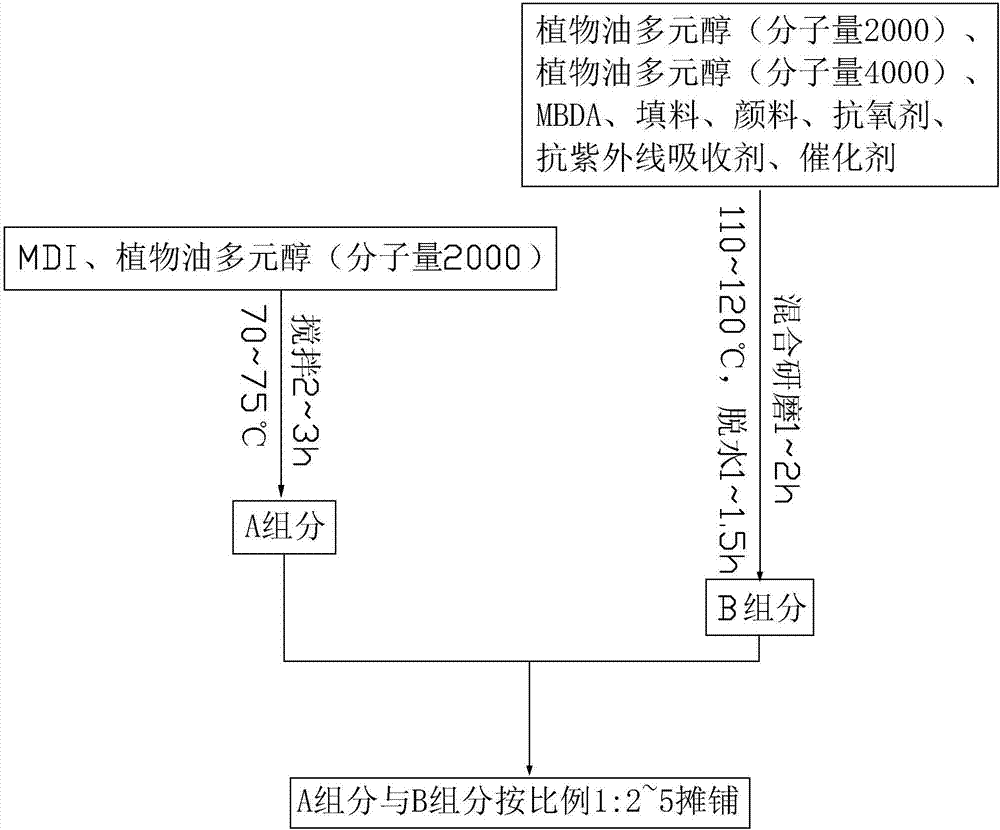

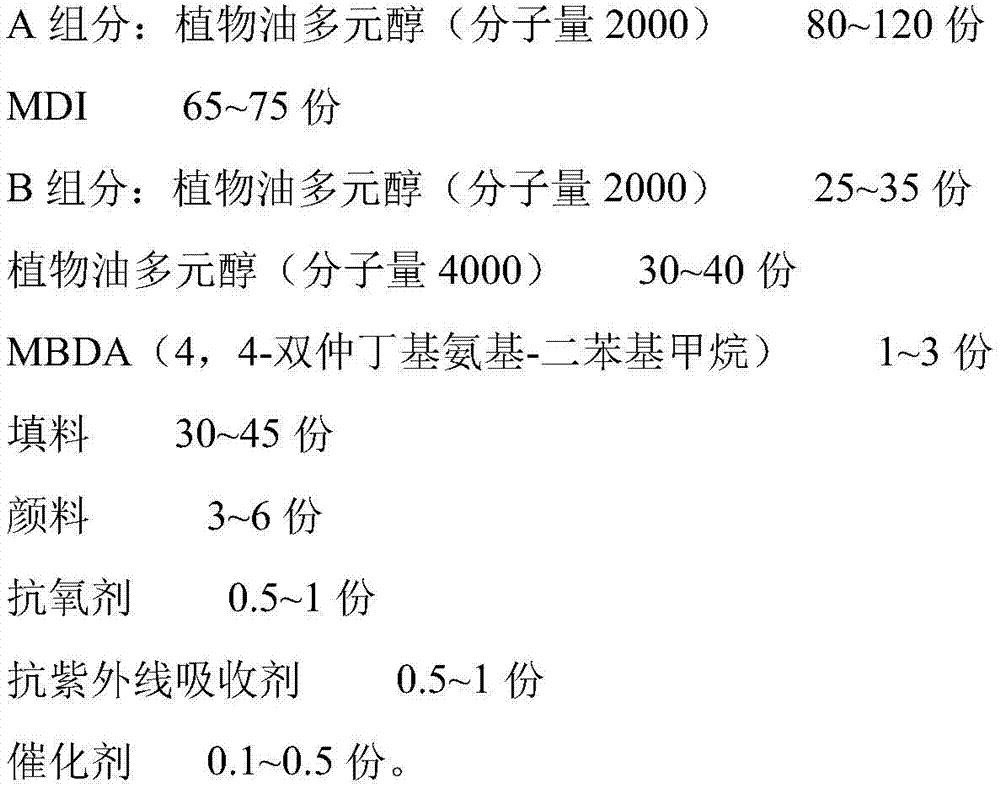

[0045] Such as figure 1 As shown, a method for preparing a synthetic surface material for a sports field is prepared according to the following mass ratio:

[0046] A component:

[0047] Soybean oil polyol (molecular weight 2000) 80kg

[0048] MDI 65kg

[0049] Add the measured amount of component A into the reactor, raise the temperature to 70°C, and stir for 2 hours to obtain component A.

[0050] B component:

[0051] Castor oil polyol (molecular weight 2000) 25kg

[0052] Castor oil polyol (molecular weight 4000) 30kg

[0053] MBDA 1kg

[0054] 400 mesh talcum powder 30kg

[0055] Iron oxide red 5kg

[0056] Antioxidant 264 0.5kg

[0057] Anti-ultraviolet absorber UV-81 0.5kg

[0058] Rare earth naphthenate 0.1kg

[0059] Bismuth isooctanoate catalyst 0.1kg.

[0060] Add the measured amount of component B into the reactor, stir and mix, grind for 2 hours, raise the temperature to 110°C, and dehydrate under vacuum for 1.5 hours to obtain component B.

[0061]Wh...

Embodiment 2

[0063] A component:

[0064] Soybean oil polyol (molecular weight 2000) 90kg

[0065] MDI 67kg

[0066] B component:

[0067] Castor oil polyol (molecular weight 2000) 27kg

[0068] Castor oil polyol (molecular weight 4000) 32kg

[0069] MBDA 1kg

[0070] 400 mesh talcum powder 33kg

[0071] Iron Oxide Red 6kg

[0072] Antioxidant 264 0.6kg

[0073] Anti-ultraviolet absorber UV-81 0.6kg

[0074] Rare earth naphthenate 0.2kg

[0075] Bismuth isooctanoate catalyst 0.1kg.

Embodiment 3

[0077] A component:

[0078] Soybean oil polyol (molecular weight 2000) 100kg

[0079] MDI 69kg

[0080] B component:

[0081] Castor oil polyol (molecular weight 2000) 29kg

[0082] Castor oil polyol (molecular weight 4000) 34kg

[0083] MBDA 2kg

[0084] 400 mesh talcum powder 36kg

[0085] Iron Oxide Red 6kg

[0086] Antioxidant 264 0.7kg

[0087] Anti-ultraviolet absorber UV-81 0.7kg

[0088] Rare earth naphthenate 0.1kg

[0089] Bismuth isooctanoate catalyst 0.2kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com